A kind of jelly and preparation method thereof

A production method and technology of jelly, applied in food ingredients as thickeners, food ingredients as emulsifiers, food homogenization, etc., can solve problems such as spoilage, denaturation, and flocculation in appearance, and achieve high fat content and increased The effect of increasing nutrition and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

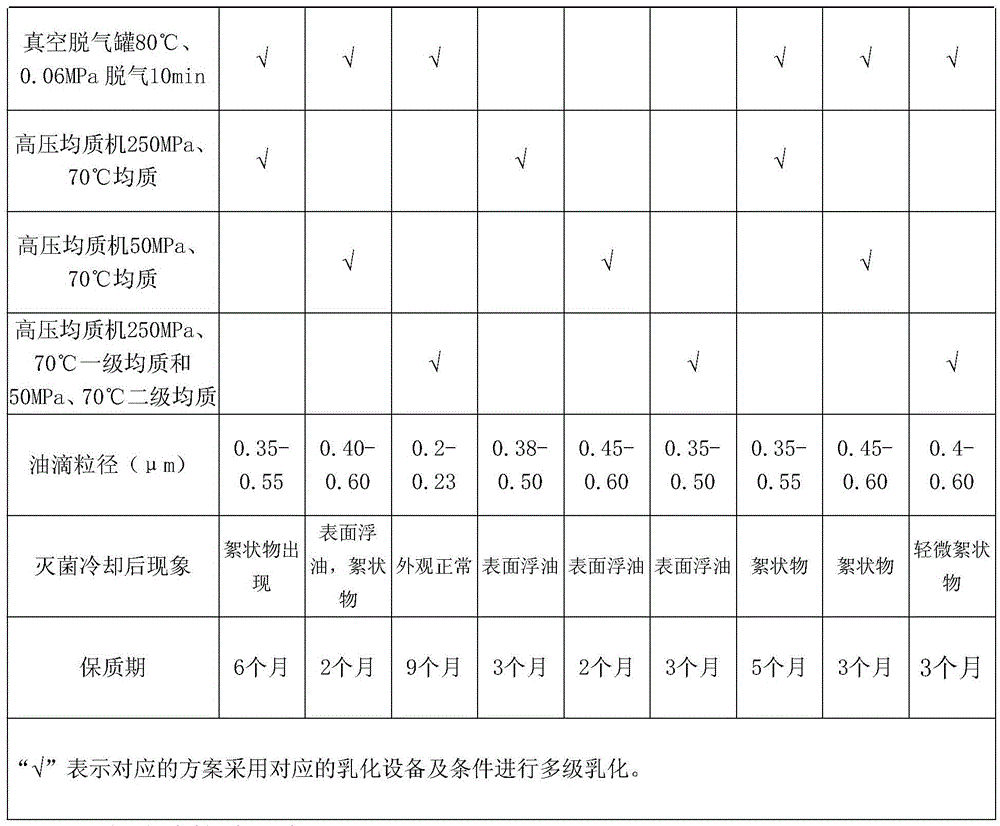

[0026] Dry the cleaned jujubes in an environment with a temperature of 40-50°C and a relative humidity of 50-60% for 24 hours, cut into 0.3-0.5cm jujube grains for later use; put 8-11 parts of milk powder, 60-65°C in an emulsification tank Mix 64-88 parts of process water in a ratio of 1:8, emulsify and shear at a shear speed of 2000r / min for 8-10min to form a preliminary emulsion, then add 0.1-0.15 parts of emulsifier, 6-10 parts of oil, Emulsify and shear at a shear speed of 2000r / min to form a uniform emulsion; heat 6-12 parts of process water, 0.3-0.4 parts of thickener, and 10-15 parts of white sugar to 85°C and mix and stir for 10 minutes in a cooking tank. Then pump the emulsion in the emulsification tank to the cooking tank, stir and mix at a stirring speed of 60r / min for 30 minutes, add baking soda to adjust the pH of the mixture to 6.5-7.0; pump the adjusted pH to In the emulsification shear pump, keep warm at 85°C for 10min at a shear stirring speed of 2000r / min, ke...

Embodiment 2

[0028] Dry the cleaned jujubes in an environment with a temperature of 40-50°C and a relative humidity of 50-60% for 24 hours, cut into 0.3-0.5cm jujube grains for later use; put 8-11 parts of whole milk powder, 60- Mix 64-88 parts of process water at 65°C in a ratio of 1:8, emulsify and shear at a shear speed of 2000r / min for 8-10 minutes to form a preliminary emulsion, then add 0.1-0.15 parts of emulsifier, 6-10 parts Grease, emulsified and sheared into a uniform emulsion at a shear speed of 2000r / min; heat 6-12 parts of process water, 0.3-0.4 parts of thickener, and 10-15 parts of white sugar in a cooking tank to 85 ° C and mix and stir After 10 minutes, pump the emulsion in the emulsification tank to the cooking tank, stir and mix at a stirring speed of 60r / min for 30 minutes, add baking soda to adjust the pH of the mixture to 6.5-6.8; Pumped to the emulsification shear pump and kept at 85°C for 10min at a shear stirring speed of 2000r / min, kept at 80°C for 10min at a vacu...

Embodiment 3

[0031] Dry the cleaned jujubes in an environment with a temperature of 40-50°C and a relative humidity of 50-60% for 24 hours, cut into 0.3-0.5cm jujube grains for later use; put 8 parts of whole milk powder, 60-65°C in an emulsification tank Mix 64 parts of process water, emulsify and shear at a shear speed of 2000r / min for 8min to form a preliminary emulsion, then add 0.15 parts of monoglyceride and 6 parts of coconut oil, emulsify and shear at a shear speed of 2000r / min to form a uniform Emulsion: Heat 6 parts of process water, 0.3 parts of guar gum, and 10 parts of white sugar in the cooking tank to 85°C and mix and stir for 10 minutes, then pump the emulsion in the emulsification tank to the cooking tank at a rate of 60r / After stirring and mixing at a stirring speed of min for 30 minutes, add sodium bicarbonate to adjust the pH of the mixed material liquid to 6.5; pump the pH-adjusted material liquid to an emulsifying shear pump in turn and keep it warm at 85°C with a she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com