A kind of neutral milk pudding and preparation method thereof

A milk pudding technology and a production method are applied in the directions of food ingredients as thickeners, food ingredients as emulsifiers, oil-containing food ingredients, etc., and can solve problems such as spoilage, denaturation, appearance flocculation, etc., and achieve high fat content, The effect of increasing nutrition and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

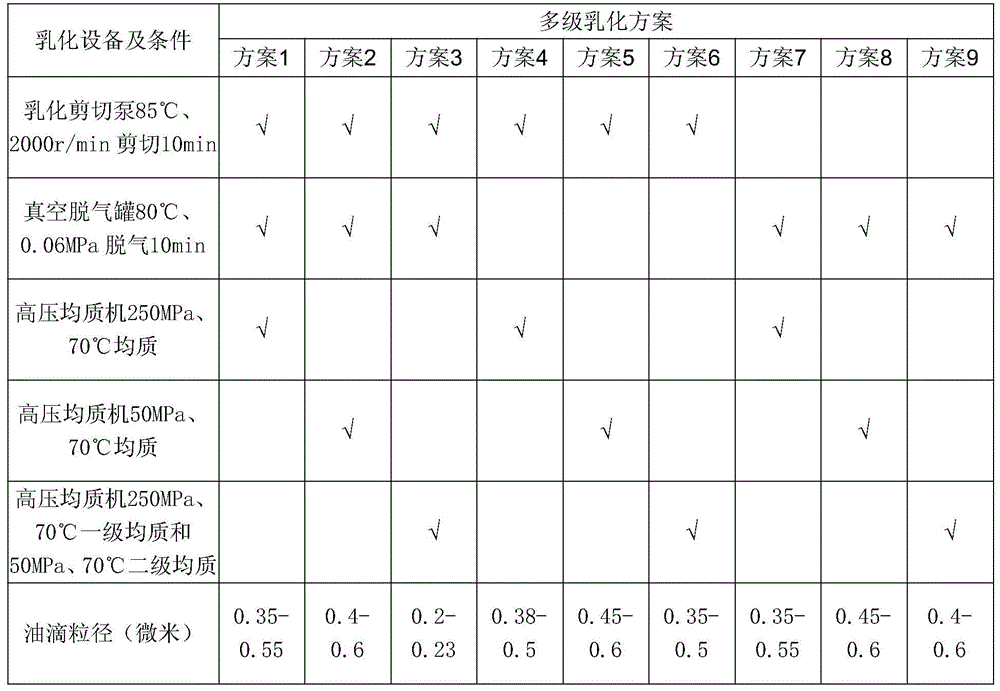

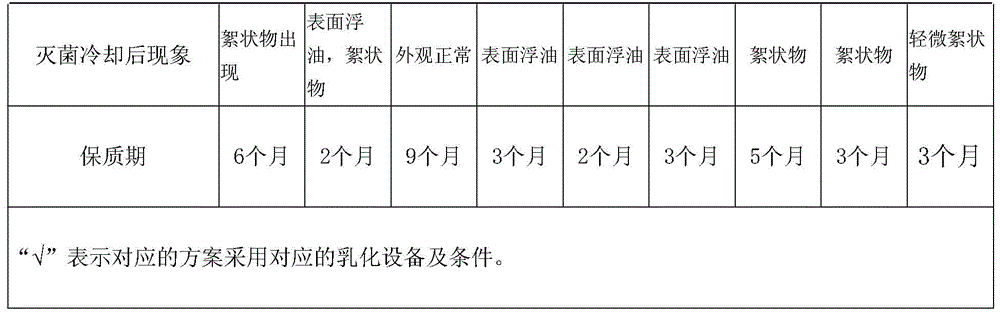

[0024] In the emulsification tank, mix 8-11 parts of milk powder and 64-88 parts of process water at 60-65 ° C in a ratio of 1:8, and emulsify and shear at a shear speed of 2000r / min for 8-10min to form a preliminary emulsion. Then add 0.1-0.15 parts of emulsifier, 6-10 parts of oil, emulsify and cut into a uniform emulsion at a shear speed of 2000r / min; put 6-12 parts of process water and 0.3-0.4 parts of thickener in the cooking tank 1. Heat 10-15 parts of white sugar to 85°C and mix and stir for 10 minutes, then pump the emulsion in the emulsification tank to the cooking tank, stir and mix at a stirring speed of 60r / min for 30 minutes, add baking soda to adjust the pH of the mixture to 6.0-7.0; the feed liquid with adjusted pH is sequentially pumped to the emulsification shear pump and kept at 85°C for 10 minutes at a shear stirring speed of 2000r / min, and kept at a vacuum degree of 0.06MPa for 80 Degassing at ℃ for 10 minutes, first-stage homogenization at 65-80°C and pres...

Embodiment 2

[0026] In the emulsification tank, mix 8-11 parts of whole milk powder and 64-88 parts of process water at 60-65°C in a ratio of 1:8, emulsify and shear at a shear speed of 2000r / min for 8-10min, and form a preliminary milky state Add 0.1-0.15 parts of emulsifier, 6-10 parts of oil, and emulsify and cut into a uniform emulsion at a shear speed of 2000r / min; add 6-12 parts of process water and 0.3-0.4 parts of Thickener, 10-15 parts of white sugar, heated to 85°C, mixed and stirred for 10 minutes, then pumped the emulsion in the emulsification tank to the cooking tank, stirred and mixed at a stirring speed of 60r / min for 30 minutes, then added baking soda to dissolve the mixture Adjust the pH to 6.5-6.8; pump the pH-adjusted feed liquid to the emulsification shear pump in turn, keep it warm at 85°C for 10 minutes at a shear stirring speed of 2000r / min, and put it in a vacuum degassing tank at a vacuum degree of 0.06MPa Insulate at 80°C and degas for 10 minutes, first-stage homo...

Embodiment 3

[0029] Mix 8 parts of whole milk powder with a protein content of 30% and 64 parts of process water at 60°C in an emulsification tank, emulsify and shear at a shear speed of 2000r / min for 8 minutes to form a preliminary emulsion, and then add 0.15 parts of monoglycerides Ester, 6 parts of coconut oil, emulsified and sheared at a shear speed of 2000r / min to form a uniform emulsion; heat 6 parts of process water, 0.3 parts of guar gum, and 10 parts of white sugar to 85°C in a cooking tank and mix and stir After 10 minutes, pump the emulsion in the emulsification tank to the cooking tank, stir and mix at a stirring speed of 60r / min for 30 minutes, add baking soda to adjust the pH of the mixture to 6.5; pump the adjusted pH to In the emulsification shear pump, keep warm at 85°C for 10min at a shear stirring speed of 2000r / min, keep warm at 80°C for 10min at a vacuum degree of 0.06MPa in a vacuum degasser, and degas at 80°C for 10min at a vacuum degree of 0.06MPa, and in a high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com