Production process of hard toffee with high milk content

A production method and milk quantity technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of poor milk taste, insufficient milk taste concentration, and delicate taste, and achieve high milk content and taste. Smooth, glossy soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

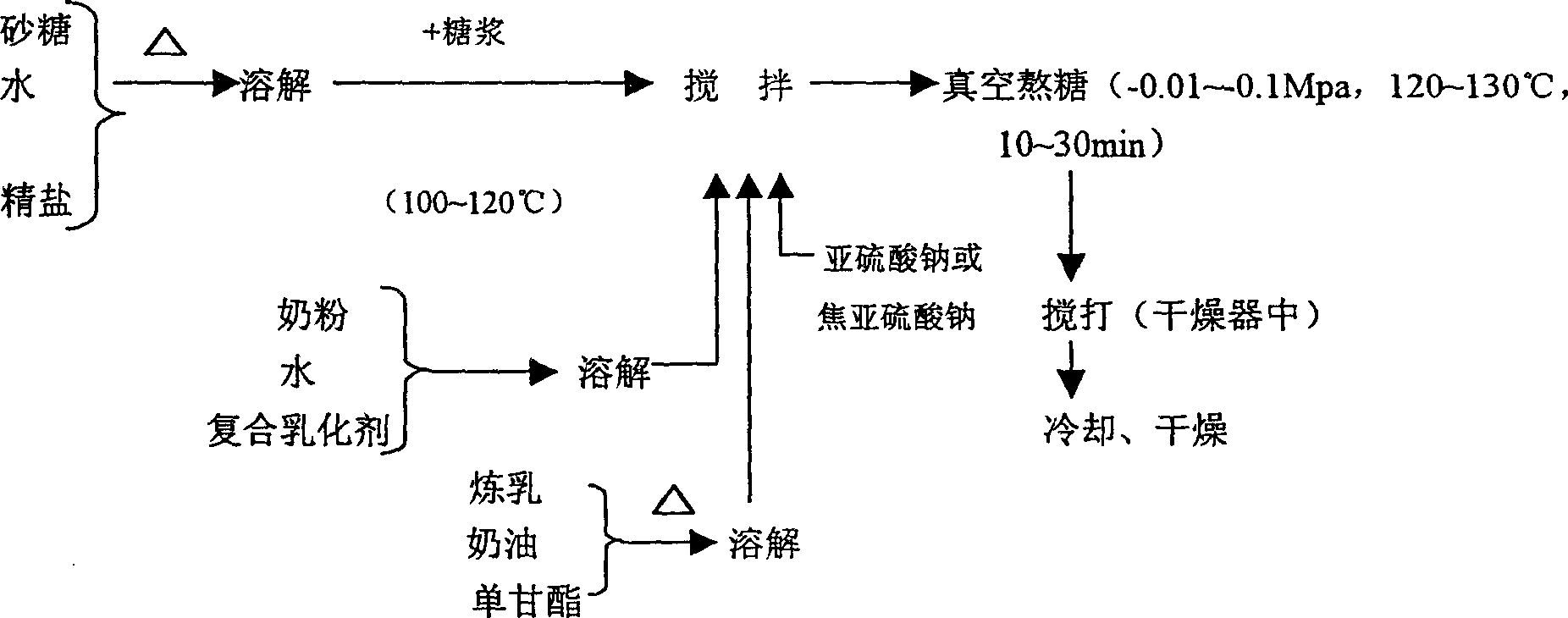

[0035] figure 1 For the process flow diagram of the present invention, toffee is produced according to its process steps, namely:

[0036] (1) Add 0.03 g of sucrose ester, 0.06 g of diacetyl tartrate monoglyceride, and 4 g of milk powder into 1.5 g of water, and stir until dissolved while adding the milk powder;

[0037] (2) Mix 3 grams of condensed milk, 0.5 grams of cream, and 0.001 grams of monoglyceride, and heat to dissolve;

[0038] (3) Heat 6 grams of refined sugar and 0.01 grams of refined salt, dissolve them thoroughly in 1.5 grams of water, then add 10 grams of syrup, heat, and control the temperature between 100 and 120°C, then add the milk powder of (1) and (2) and cream, and 0.005 g of sodium sulfite or sodium metabisulfite, stirred;

[0039] (4) Vacuum boiling sugar: the massecuite obtained in (3) is evacuated and heated and boiled, the vacuum degree is -0.05 MPa, the temperature is 125 ° C, and the time is 20 minutes;

[0040] (5) Stirring: put the boiled mas...

Embodiment 2

[0043] Produce toffee by the technique of embodiment 1, difference is to take following operation respectively:

[0044] (1) No emulsifier added;

[0045] (2) Add sucrose ester: 0.1 g;

[0046] (3) Add sucrose ester: 0.01 g, diacetyl tartrate monoglyceride: 0.09 g

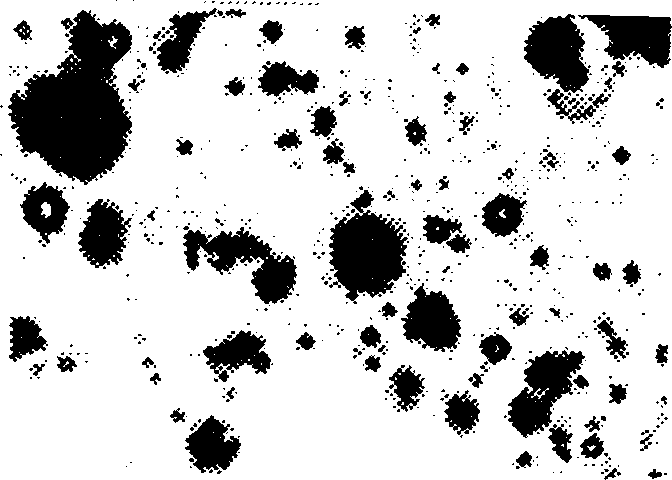

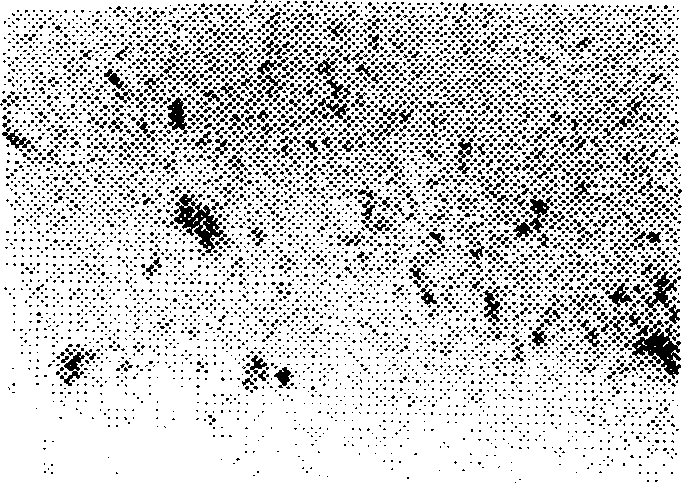

[0047] The toffee produced respectively is observed under a microscope, and it is observed that (1) the result of the toffee produced is as follows: figure 2 As shown, the result of the toffee produced in (2) is as image 3 As shown, the result of the toffee produced in (3) is as Figure 4 shown. The results indicated that the effect of compound emulsifier was better than that of single use, and the distribution of each phase of the system was uniform. It can be seen that appropriate emulsifiers and appropriate amounts can greatly improve the internal structure of sugar bodies. The evaluation of the toffee produced in (3) is as follows: strong milky aroma, moderate sweetness, smooth texture, non-greasy, soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com