Automatic stone removing, slicing and classifying integrated machine for hawthorns

An all-in-one machine and hawthorn core technology, which is applied in the field of hawthorn automatic pitting and slicing sorting machine, can solve the problems of large size difference, uneven thickness, and low utilization rate of hawthorn slices, achieve consistent size and thickness, and improve profitability , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

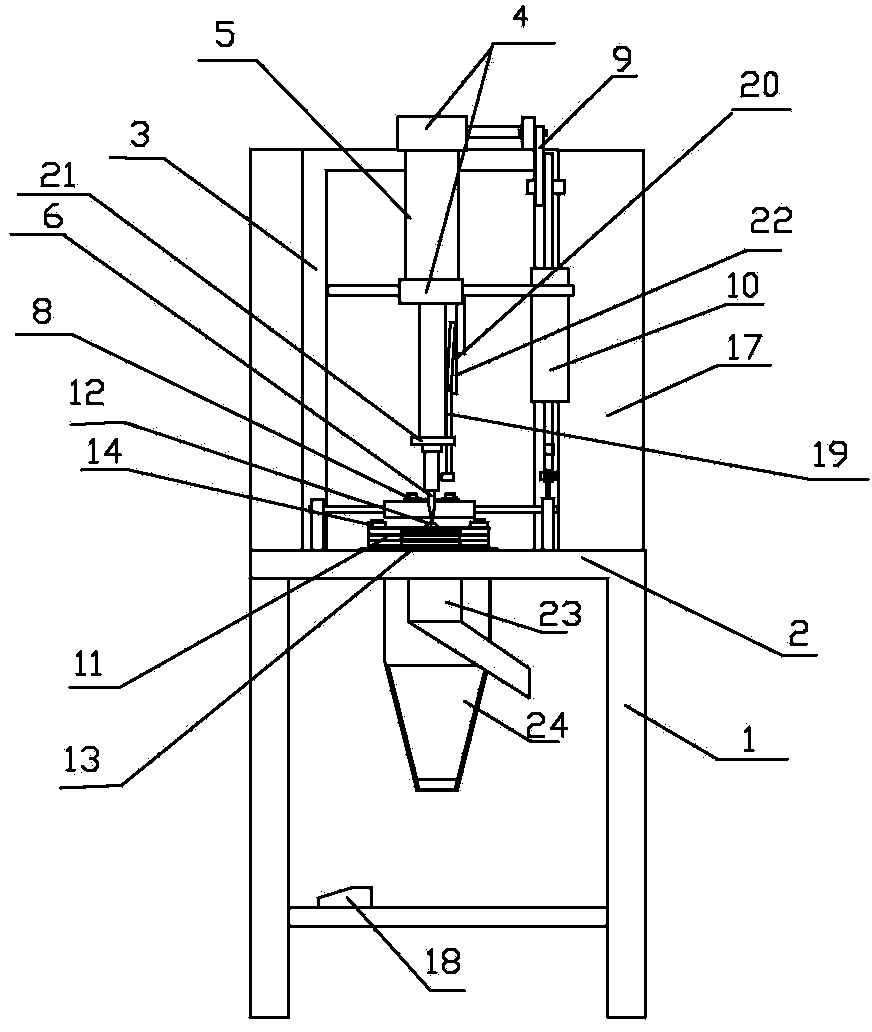

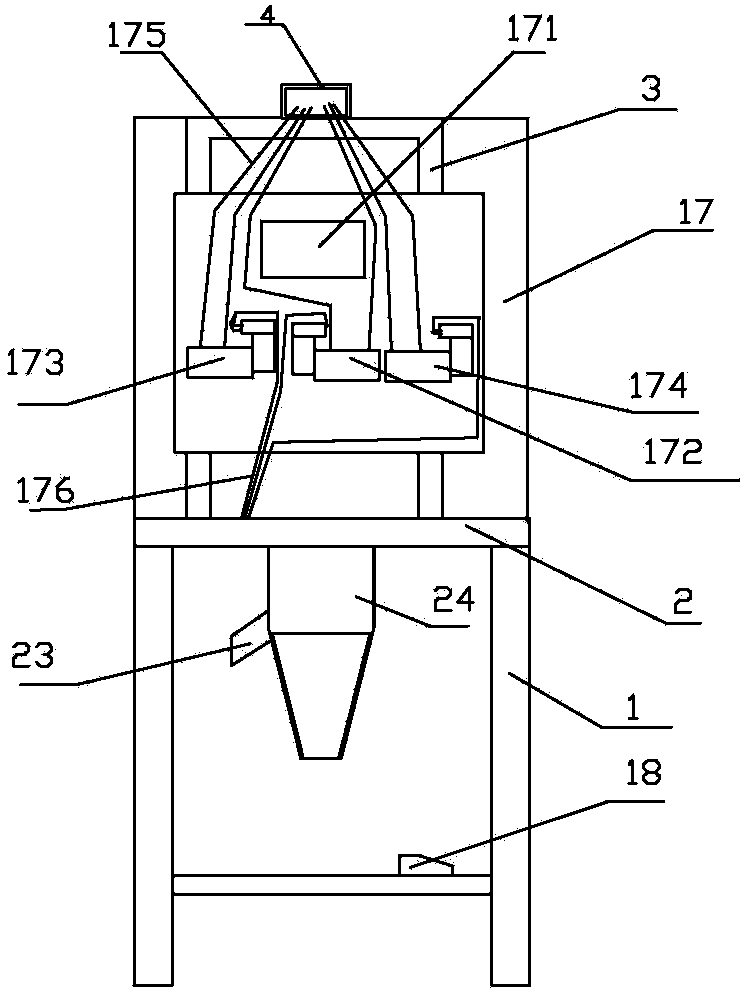

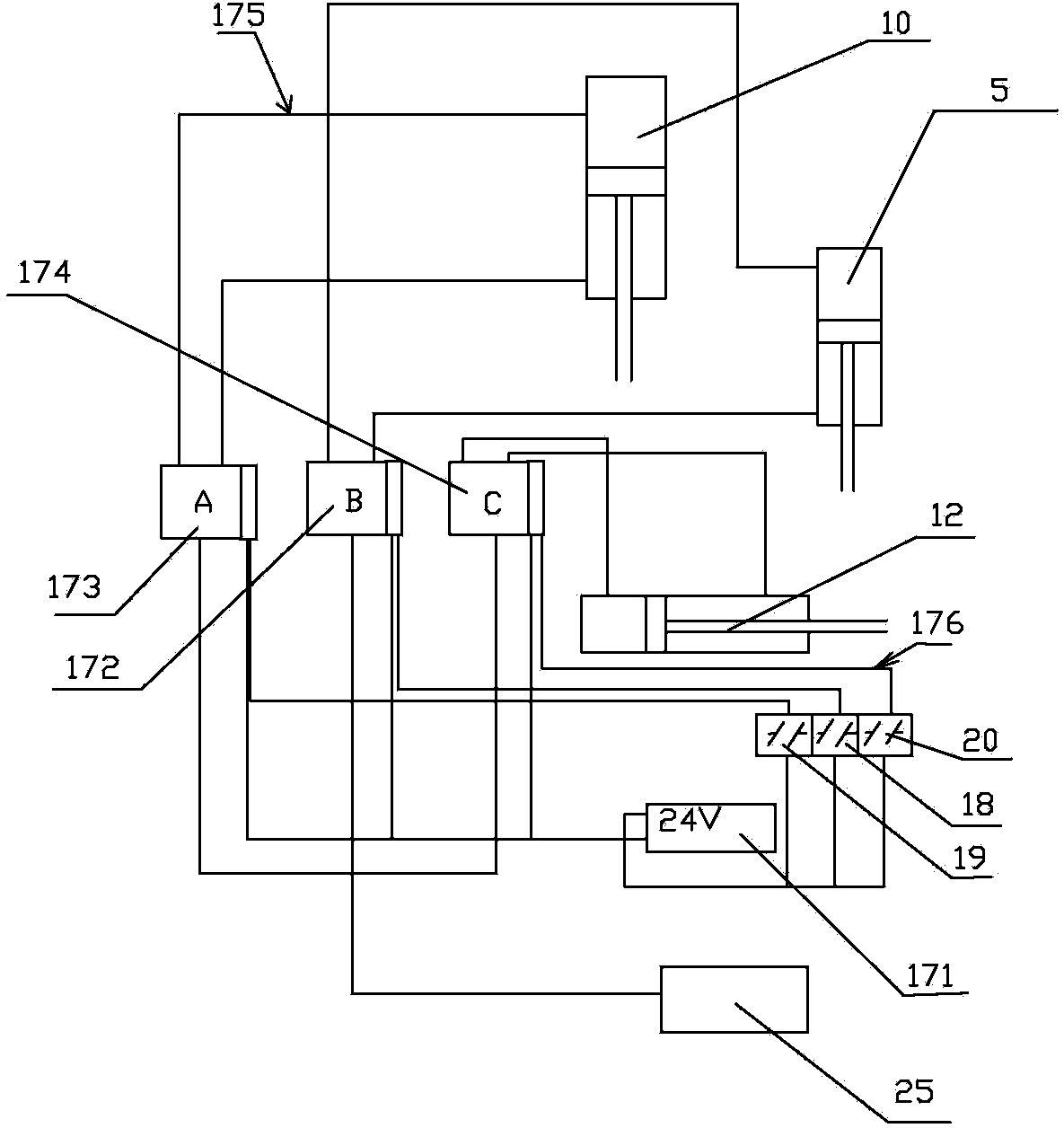

[0024] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 An example is given. refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8Make the invention. The hawthorn automatic pitting and slicing sorting machine includes frame legs 1 and a horizontal operating platform 2, the horizontal operating platform 2 is arranged on the upper end of the frame supporting legs 1, and a rectangular vertical frame 3 is arranged at the rear of the horizontal operating platform 2 , in the middle of the upper end of the rectangular vertical frame 3 and in the middle of the waist crossbeam of the rectangular vertical frame 3, a forward-stretching square tube 4 is provided, and it is characterized in that: the end of the forward-stretching square tube 4 is provided with a vertical top core cylinder 5, The end of the piston rod of the vertical top core cylinder 5 is provided with a hawthorn posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com