Angle steel back chipping machine facilitating scrap iron collection

An angle steel and root cleaning technology, applied in metal processing machinery parts, milling machine equipment details, maintenance and safety accessories, etc., can solve the problems of noise from the transmission mechanism, affecting the transmission effect, and iron filings retention, etc., to achieve a clean working environment, collection And the effect of cleaning iron filings quickly and easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

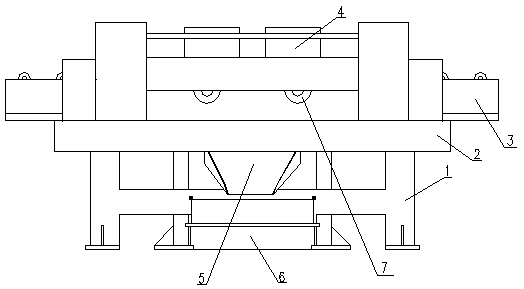

[0009] An angle steel root cleaning machine that is convenient for collecting iron filings, including a frame 1, a worktable 2, a material supporting mechanism 3 and a pressing mechanism 4, the working platform 2 is located at the upper end of the frame 1, and the material supporting mechanism 3 is located at the working The upper end of the table 2, the pressing mechanism 4 is located above the material supporting mechanism 3, and two sets of cutter heads are arranged in the supporting mechanism 3, and the lower end of the working table 2 is provided with a chip collecting bucket 5 which communicates with the upper surface of the working table 2, so that The bottom of the chip collecting bucket 5 is provided with a chip collecting groove 6 welded on the frame 1 .

[0010] The two groups of cutterheads described in the present invention are all plane milling cutterheads 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com