A device for drying plant fibers

A plant fiber and equipment technology, applied in the field of drying equipment, can solve problems such as uneven distribution of materials, and achieve the effects of avoiding dust diffusion, improving resource utilization, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

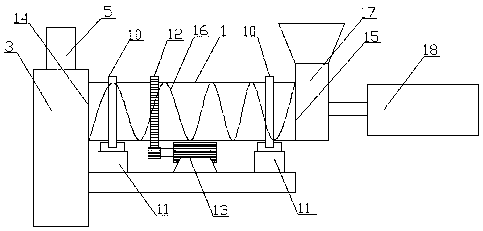

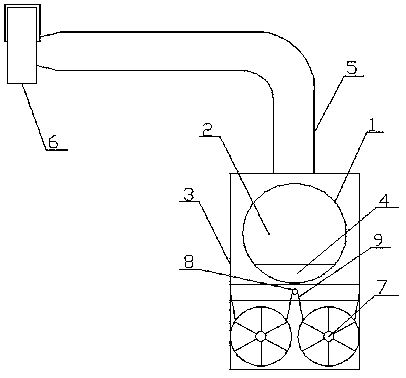

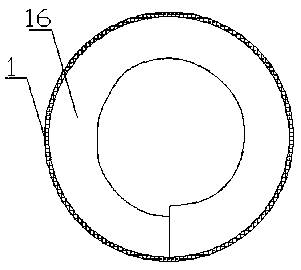

[0013] Embodiments of the present invention: a kind of equipment for drying plant fiber, as attached Figure 1-3 As shown, a drying cylinder 1 is included, and the outer wall of the drying cylinder 1 is provided with a support ring 10 and a toothed ring 12, wherein the support ring 10 is arranged on the support seat 11 below it, and the toothed ring 12 and the motor 13 on one side thereof connection; one end of the drying drum 1 is provided with a feed port 15, and the other end is provided with a discharge port 14, and the inner wall of the drying drum 1 between the feed port 15 and the discharge port 14 is provided with a spiral material guide plate 16. The feeding device 17 and the hot blast stove 18 are connected to the feeding port 15.

[0014] When the present invention works, at first the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com