A Ring Processing System

A processing system and ring technology, applied in metal processing, manufacturing tools, and other manufacturing equipment/tools, etc., can solve problems such as poor working conditions, low production efficiency, and loose fixation, and achieve high production efficiency, convenient operation, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

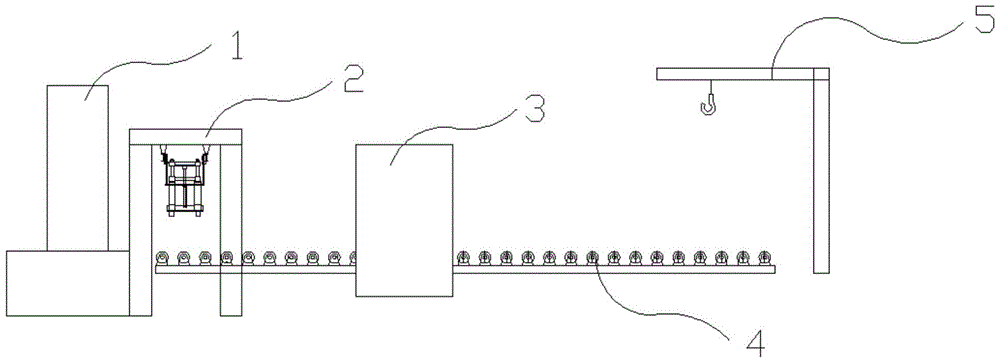

[0035] A ring processing system to achieve, the ring processing system such as figure 1 As shown, it includes a press, a ring rolling machine 1, a thermal printer 3, a cantilever crane 5, a heat treatment furnace, and also includes a ring unloading device 2 and a conveying roller table 4. The arrangement order of each link in the ring processing system is press, Ring rolling machine 1, conveying roller table 4, cantilever crane 5 and heat treatment furnace; ring rolling machine 1 and conveying roller table 4 are connected by a ring piece unloading device 2, and the height of conveying roller table 4 is lower than that of the exit of ring rolling machine 1 Height; Thermal printer 3 is located on conveying roller table 4.

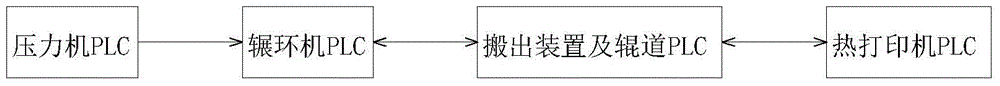

[0036] The press machine is controlled by the press machine PLC, the ring rolling machine 1 is controlled by the ring rolling machine PLC, the thermal printer 3 is controlled by the thermal printer PLC, the ring piece unloading device 2 and the conveying roll...

Embodiment 2

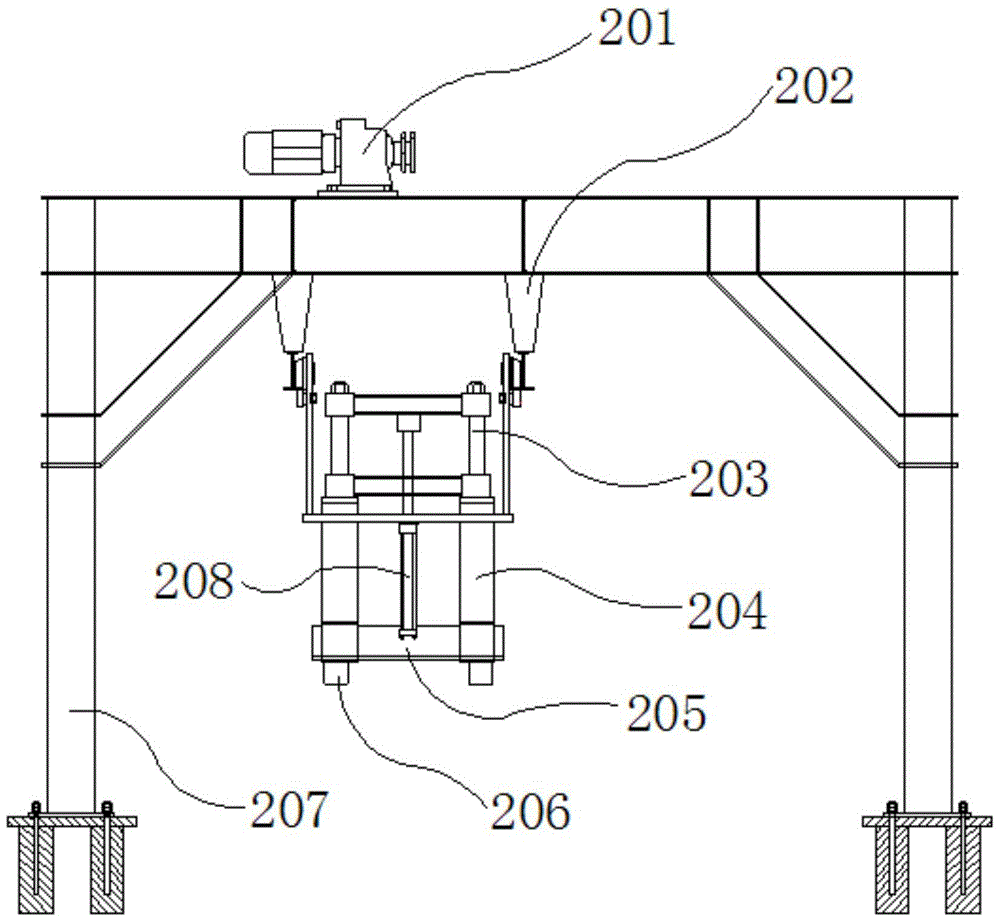

[0048] With embodiment 1, the difference is that one end of the hydraulic cylinder 208 is connected with the lower connecting rod 205 at the bottom end of the telescopic rod 203; Figure 5 As shown, the number of rollers 206 is two. The motor 201 drives the movement of the control device through chain transmission. Then, the same as in Embodiment 1, the hydraulic cylinder 208 drives the telescopic rod 203, the upper link and the roller 206 to move up and down. The expansion and contraction of the hydraulic cylinder 208 drives the roller 206 to move up and down. When the roller 206 reaches the center of the ring, the hydraulic cylinder 208 is extended, and the telescopic rod 203, the upper link, the lower link 205 and the roller 206 are all downward. movement, the roller 206 is inserted into the ring, and the motor 201 is started at this time, and the motor 201 drives the movement of the control device, thereby achieving the effect of moving the ring from the ring rolling mach...

Embodiment 3

[0050] Same as embodiment 1, the difference is that the number of rollers 206 can be five.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com