Fat edge detection device for rail

A detection device and a technology for rails, which are used in railway vehicle shape measuring instruments, transportation and packaging, and railway vehicle body parts, etc., can solve the problems of high equipment operating costs, biased detection data, time-consuming and labor-intensive, etc., and achieve low equipment manufacturing costs. , Easy to operate, easy to polish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing of description, the present invention will be further described.

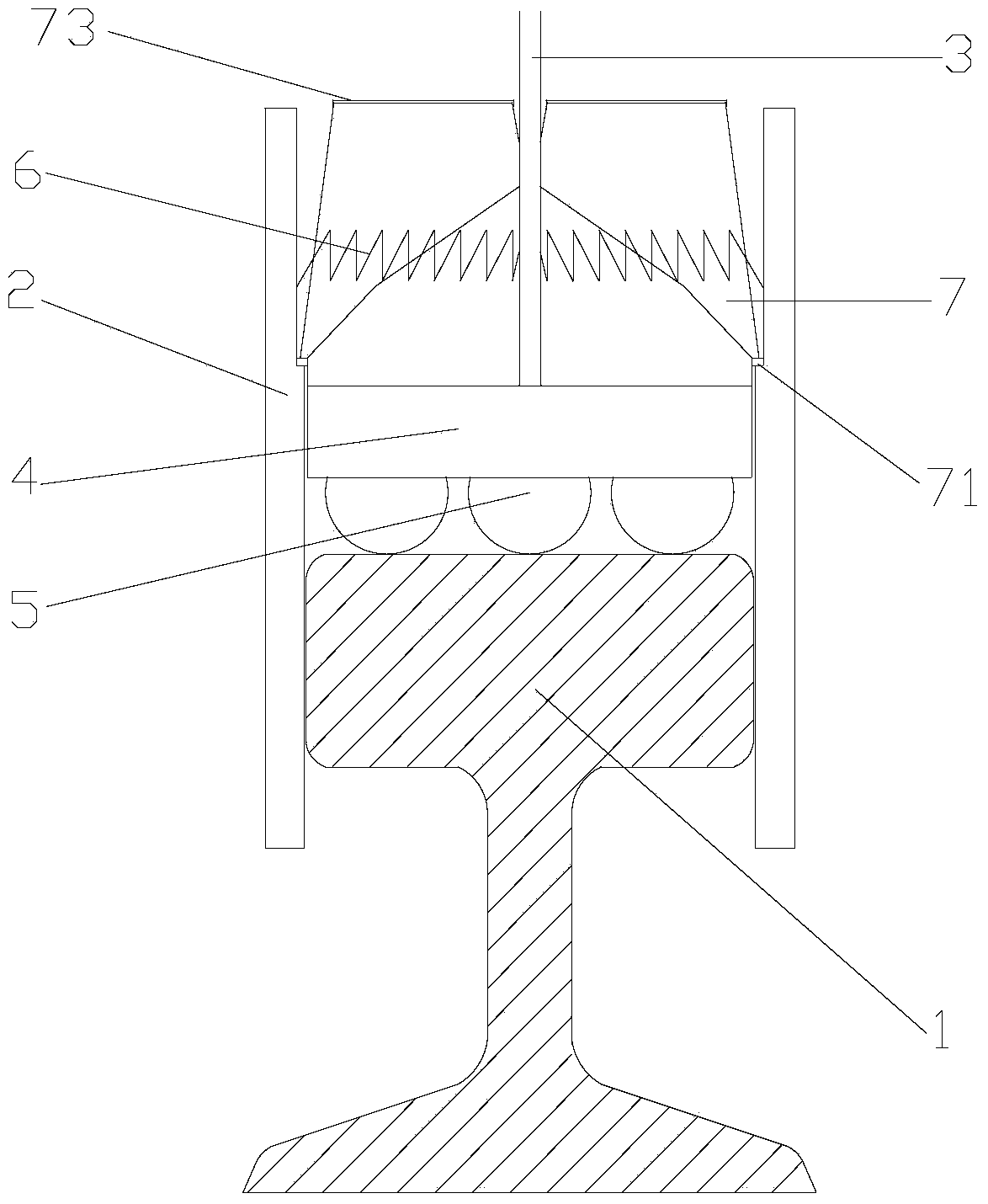

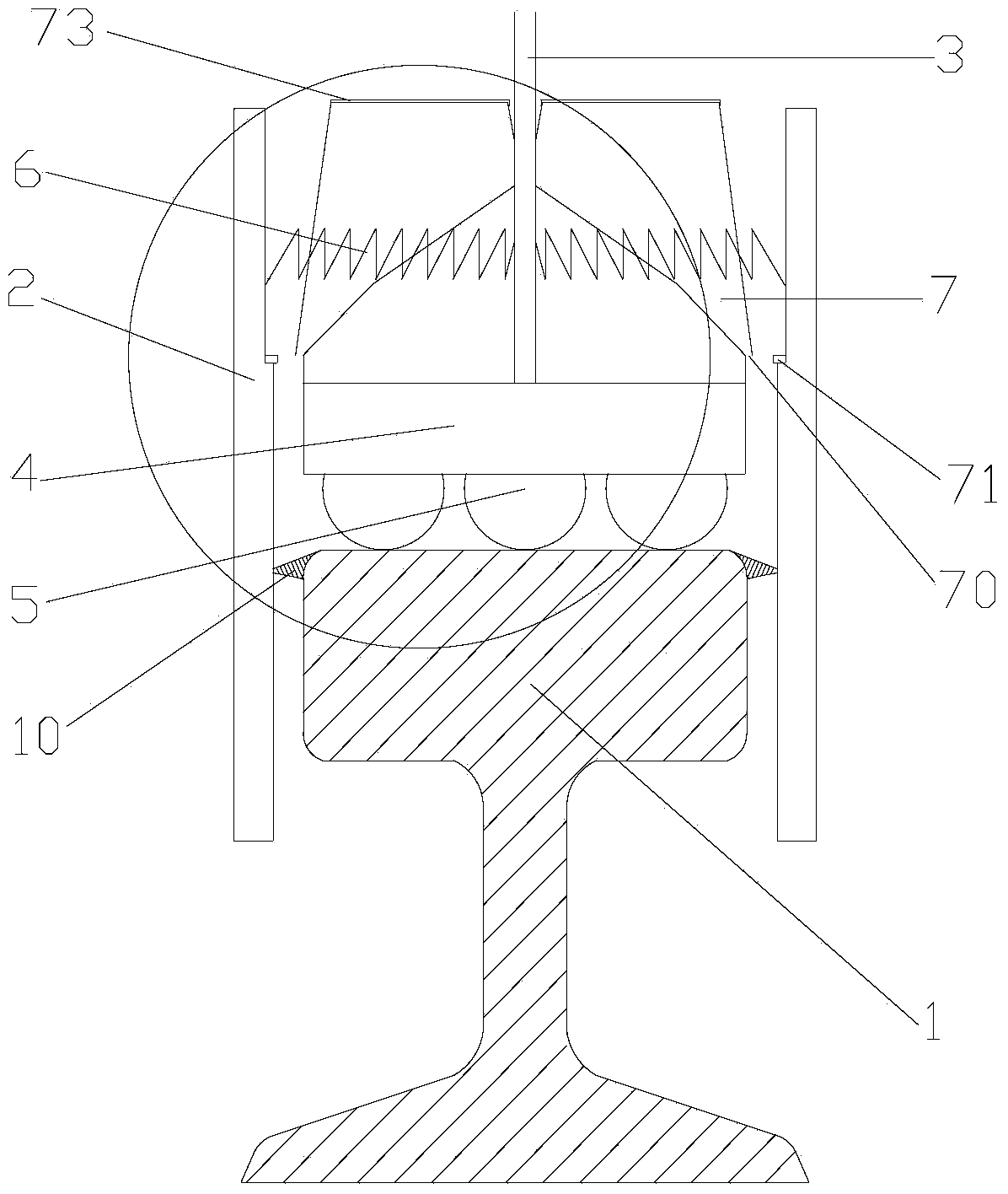

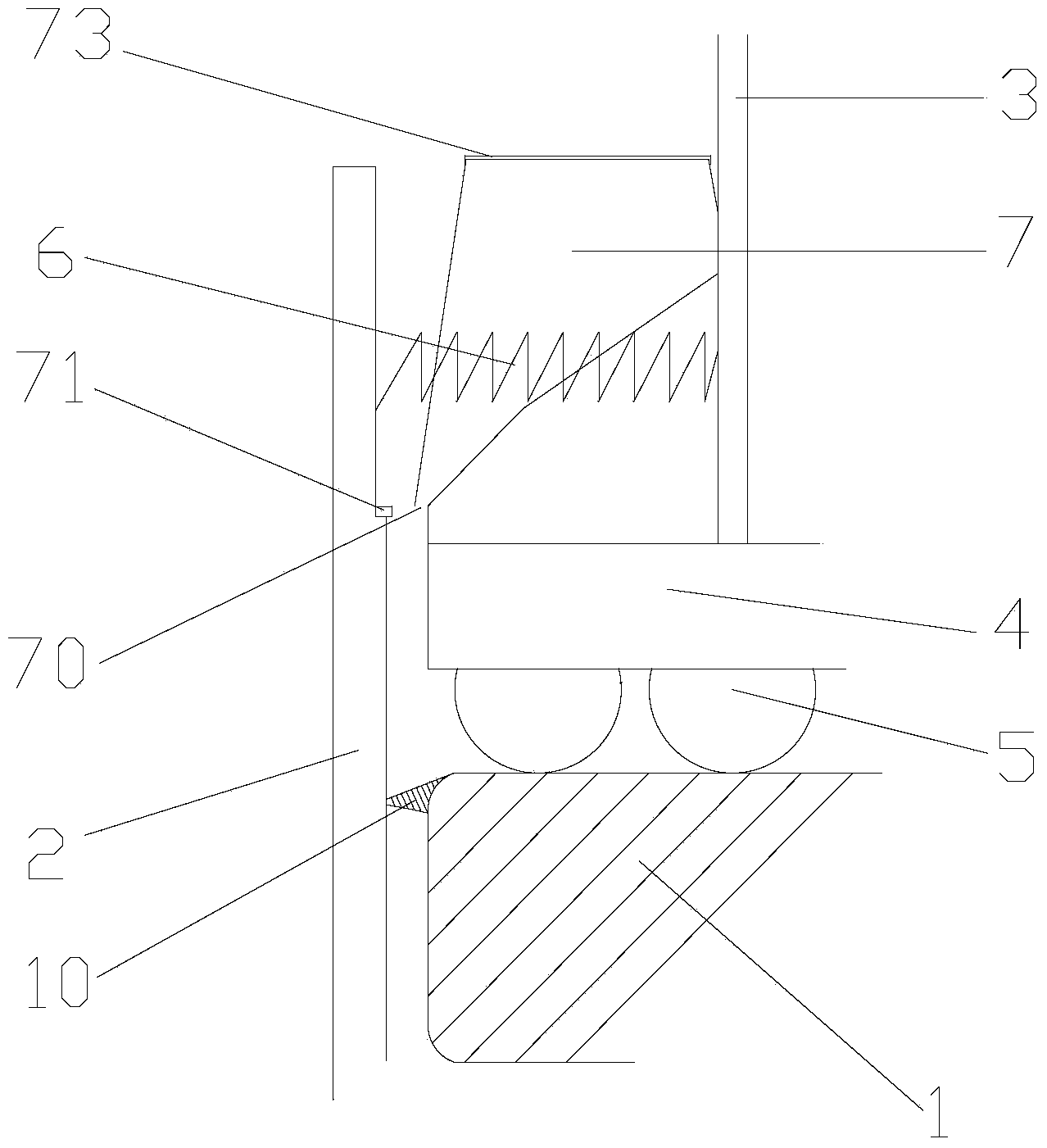

[0021] Such as figure 1 , figure 2 and image 3 As shown, a rail fat edge detection device includes a rail roller that can roll along the rail surface 1 and a splint 2 for clamping the two sides of the rail roller and the two sides of the rail 1, the rail The width of the roller is consistent with the width of the rail surface 1 without fat edge, and the upper end surface of the rail roller is provided with a connecting rod 3; the rail roller includes a cover plate 4 connected with the connecting rod 3 and a Evenly arranged balls 5 under the cover plate 4. The splint 2 is connected to the connecting rod 3 through the spring 6, and the splint 2 can be stretched when clamping the rail surface 1 with the fat edge 10 through the spring 6; the connecting rod 3 is arranged on the top of the cover plate 4 At the center of the surface, the axial direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com