Bionic jellyfish robot driven by parallelly connected mechanical arms

A technology of mechanical arms and robots, which is applied in the direction of manipulators, water action propulsion components, ship propulsion, etc., can solve the problems of small driving force, small movement range, and unsuitability for complex marine environments, so as to reduce the weight of the whole machine and reduce the deformation range. Control, improve the effect of operability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

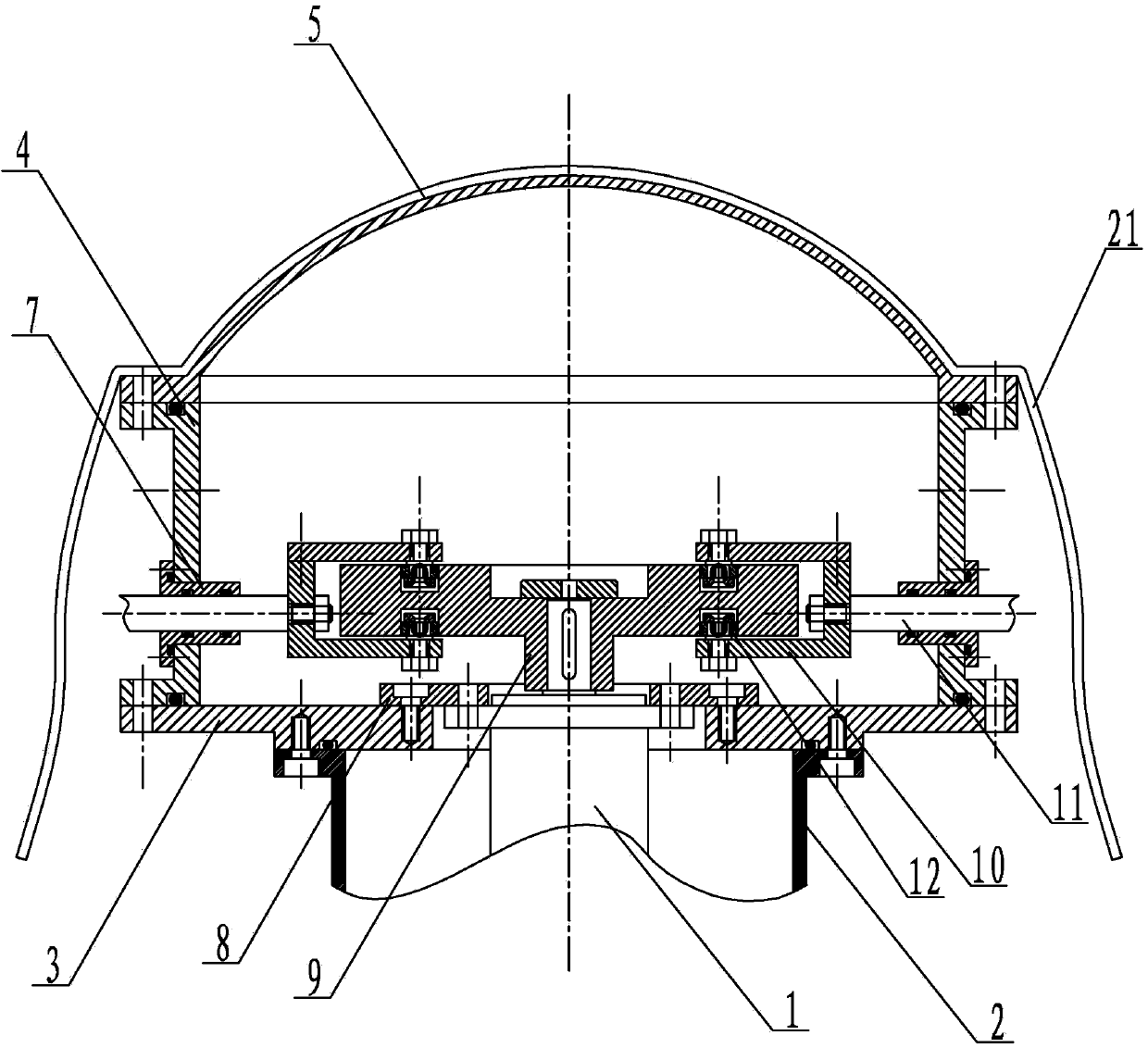

[0016] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, a bionic jellyfish robot driven by a parallel mechanical arm in this embodiment includes a drive unit 1, a base 2, a base 3, a sleeve 4, a streamlined end cover 5, a motor connecting plate 8, a cam drive plate 9, A plurality of sliding connection seats 10, a plurality of mechanical arm driving rods 11, a plurality of driving rod guide flanges 7, a plurality of roller shaft parts 12 and a plurality of flexible mechanical arms, a streamlined end cover 5, a sleeve 4, a base 3 and The base 2 is connected sequentially from top to bottom, one end of the drive unit 1 is connected through the motor connection plate 8 installed on the base 3, the cam drive disc 9 is set on the output shaft of the drive unit 1 in the sleeve 4, and the cam drive disc 9 A track groove is respectively provided along the outer contour line on the upper and lower end faces of the upper and lower ends, and the contou...

specific Embodiment approach 2

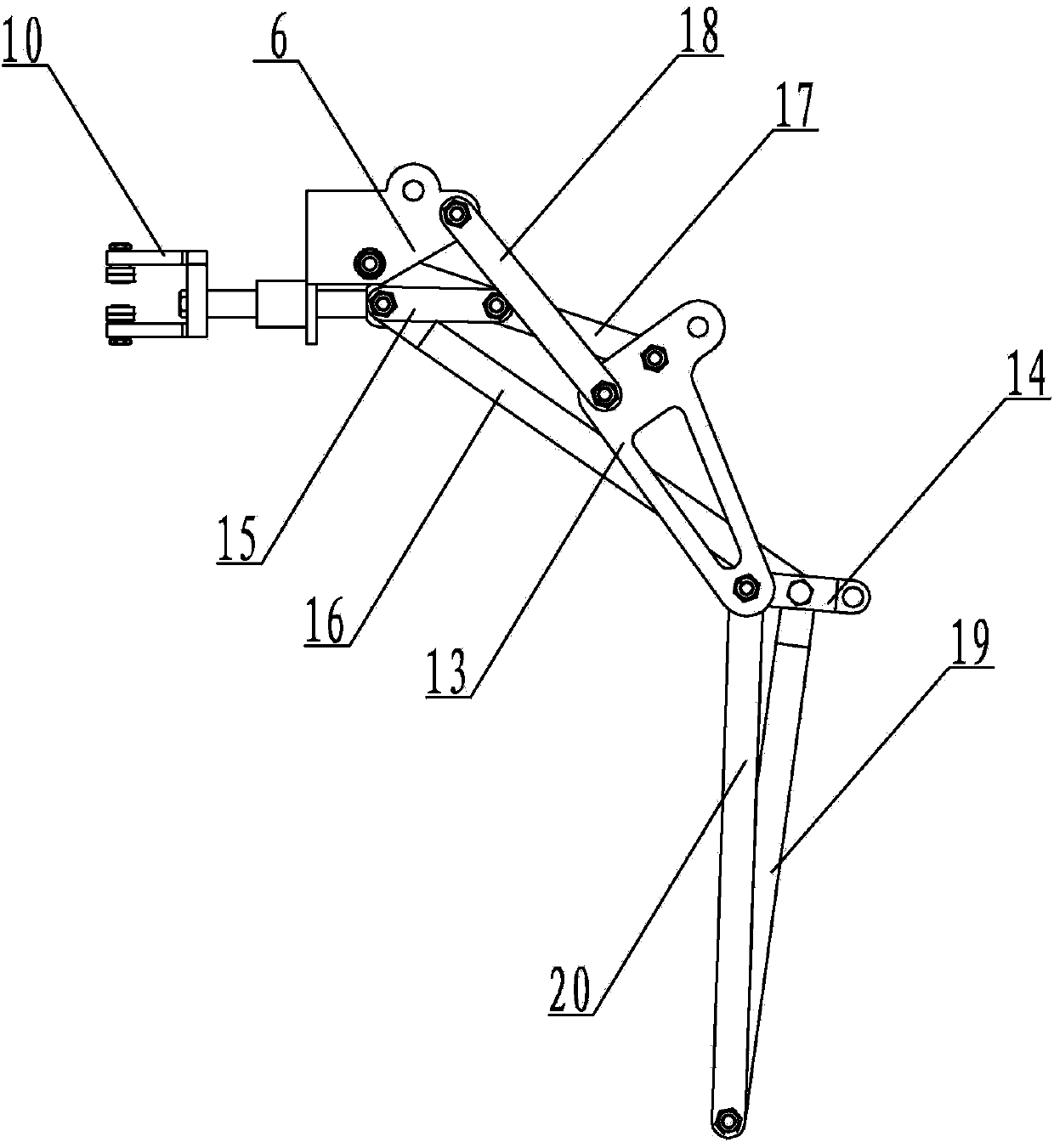

[0019] Specific implementation mode two: combination Image 6 To illustrate this embodiment, the bionic jellyfish robot of this embodiment also includes a plurality of horn bases 6 , and each flexible robotic arm is connected to each mechanical arm driving rod 11 through a horn base 6 . With such a setting, the movement is more flexible. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

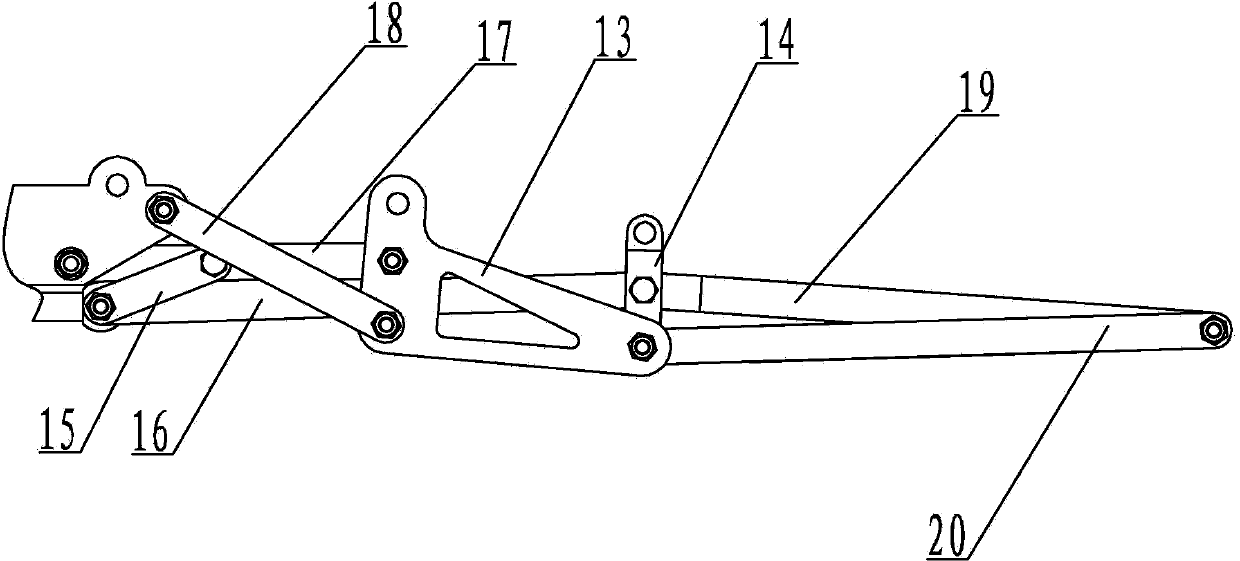

[0020] Specific implementation mode three: combination Figure 2-Figure 3 This embodiment will be described. The plurality of flexible robotic arms in this embodiment are all single-degree-of-freedom three-joint series mechanisms. So set, the movement is flexible. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com