Compact concrete slab and manufacturing method thereof

A concrete and plate technology, applied in the field of building materials, can solve problems such as the lack of rapid development of the industry, high damage rate, and low qualified rate of finished products, and achieve sustainable promotion and application of energy saving, low carbon and environmental protection, strong impact resistance, and comprehensive The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The thickness of the dense smooth concrete slab to be manufactured in this embodiment is 5mm, and the length and width are 3*3mm.

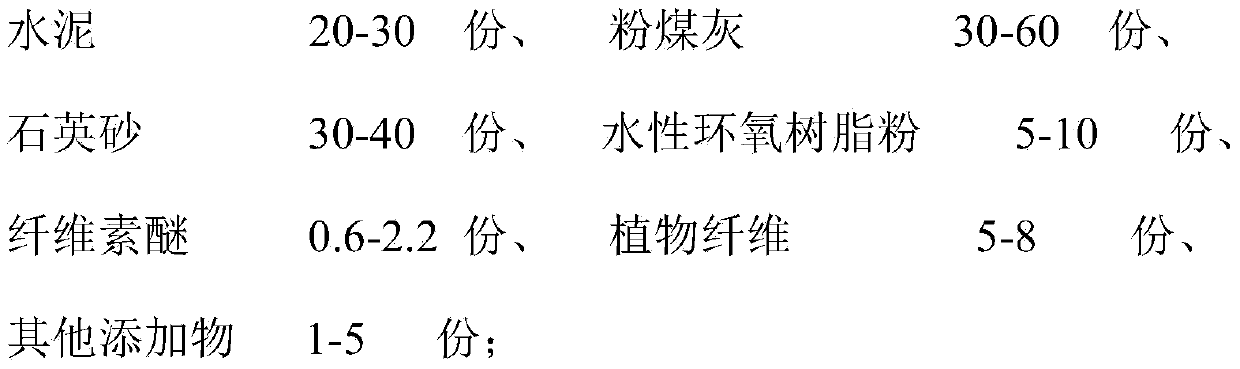

[0025] Its raw material composition and parts by weight are:

[0026]

[0027] During preparation, the raw materials are first added to the mixer for the first dry mixing and mixing, and then 13 parts of water are added for the second mixing and mixing, and then the vacuum extruder plus adjustable extrusion The green body is spirally extruded by the die nozzle to obtain the initial thickness green body; then the green body is rolled and stretched by the roller calender through the wet plastic material to obtain the final thickness green body with the thickness dimension; finally, the hob type The vertical and horizontal cutting machine obtains the final green product of dense smooth concrete slabs with the required length and width.

[0028] In the process steps, some of the equipment involved in the spiral extrusion molding of the init...

Embodiment 2

[0034] The dense smooth concrete slab to be manufactured in this embodiment has a thickness of 6mm and a length and width of 3*3mm.

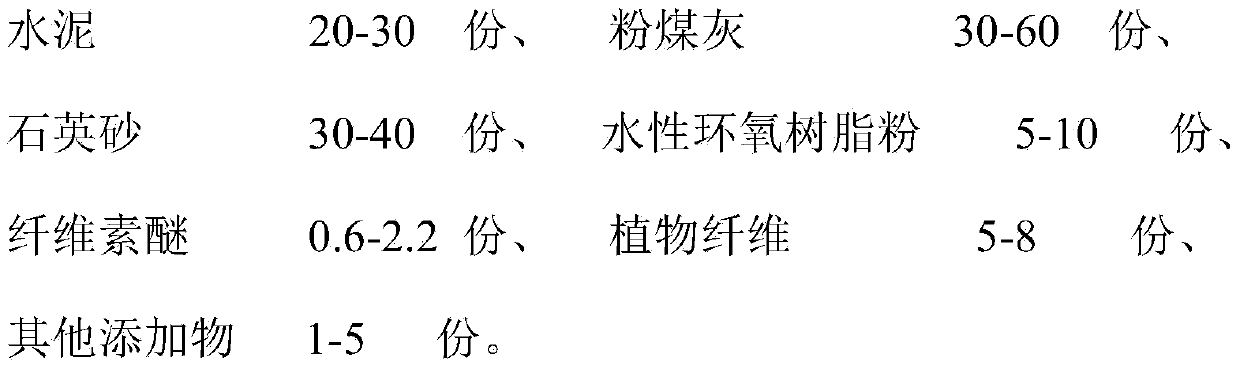

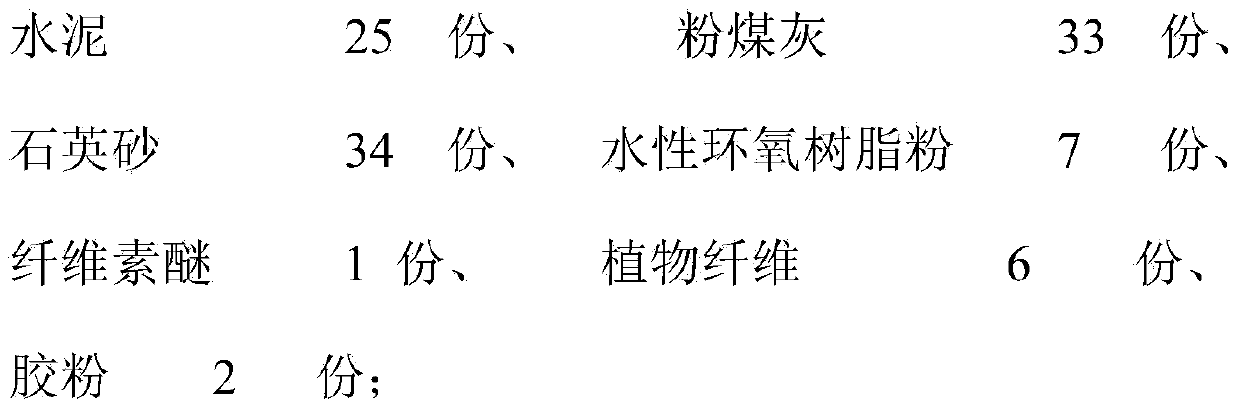

[0035] Its raw material composition and parts by weight are:

[0036]

[0037]

[0038] During preparation, the raw materials are first added to the mixer for the first dry mixing and mixing, then 15 parts of water is added for the second mixing and mixing, and then the vacuum extruder and adjustable extrusion The green body is spirally extruded by the die nozzle to obtain the initial thickness green body; then the green body is rolled and stretched by the roller calender through the wet plastic material to obtain the final thickness green body with the thickness dimension; finally, the hob type The vertical and horizontal cutting machine obtains the final green product of dense smooth concrete slabs with the required length and width.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com