The process of smelting stainless steel by electric arc furnace returning to oxygen blowing method

A stainless steel, oxygen blowing technology, applied in electric furnace, process efficiency improvement, furnace and other directions, can solve the problems of unreasonable use of voltage and current, unguaranteed tapping liquid composition, low alloy recovery rate, etc., to reduce production costs The effect of reducing the labor intensity of workers, avoiding the erosion and damage of the furnace lining, and shortening the oxygen blowing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Adopt electric arc furnace of the present invention to return to the process of smelting stainless steel by oxygen blowing method, production product model: DN400 2500lb, material: CF8C, gross weight: 4300kg, liquid weight: two castings of 9350kg, concrete implementation method is as follows:

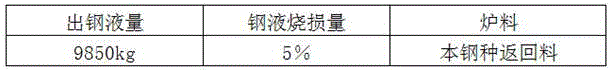

[0034] 1. Smelting technical requirements:

[0035]

[0036] 2. Ingredients: total amount of ingredients W = casting liquid weight + remaining steel + alloy + burning loss = 10360kg, ingredient list:

[0037]

[0038] Composition of returned material of this steel type: (%)

[0039] C: 0.10, Si: 0.70, Mn: 0.90, S: 0.025, P: 0.030, Cr: 18.3, Ni: 9.5, Nb: 0.49, and the rest: Fe.

[0040] Include the following steps:

[0041] Step 1. Ingredients: 90% of the charge is made of high-alloy steel of this steel type, and if there is a large charge, it is cut into small pieces; FeSi with a weight of 1.0-1.5% of the molten steel is added to the bottom of the furnace before charging,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com