led luminaire with plate radiator

A technology of LED lamps and heat sinks, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problem of heat dissipation of the shell, poor heat conduction effect of heat conduction silica gel, can not meet heat dissipation requirements, reduce LED Problems such as high lighting temperature and increased manufacturing difficulty achieve good heat conduction and heat dissipation effects, low manufacturing difficulty, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

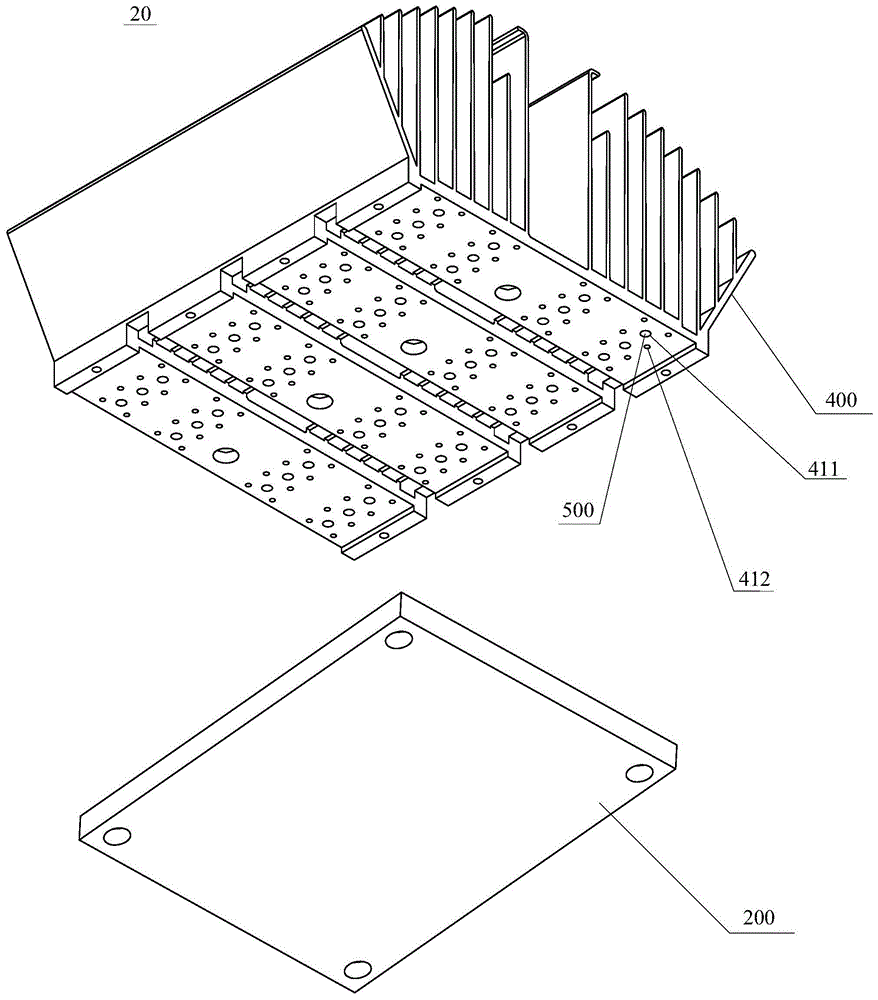

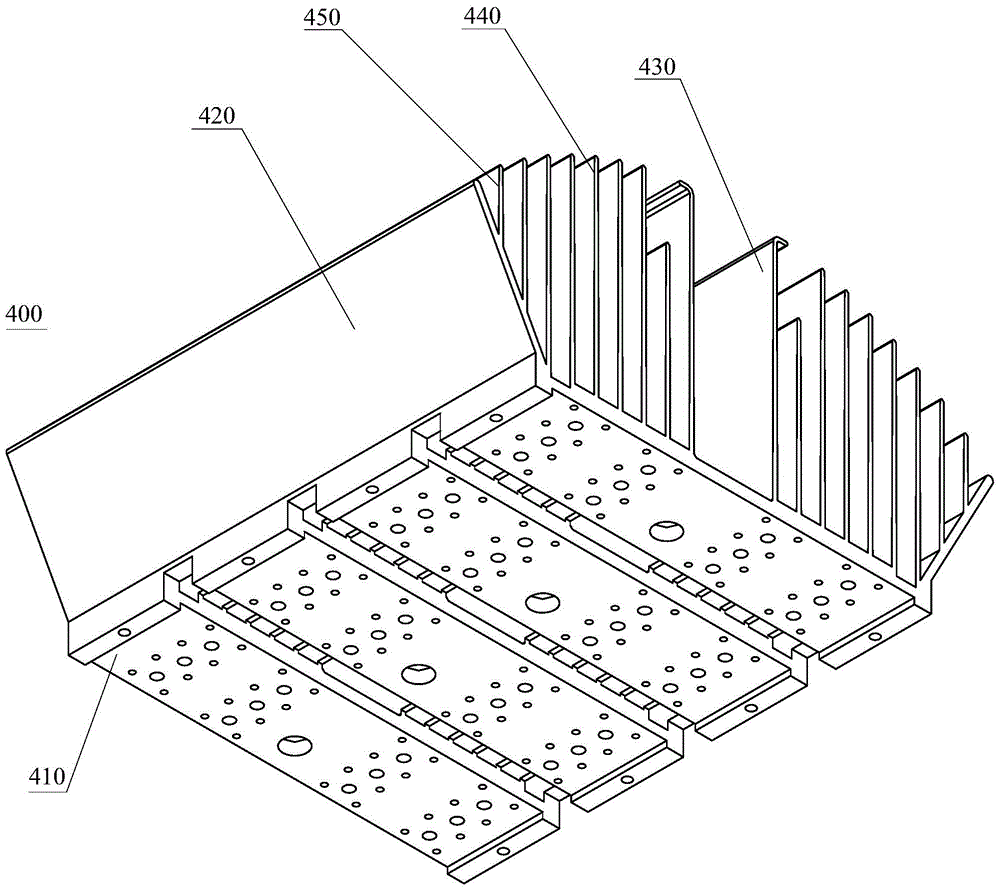

[0037] see figure 2 , the LED lamp with a plate heat sink is an LED lamp 20 with a flat heat sink, which includes a flat heat sink 400 , several LED chips (Chip) 500 and a diffusion plate 600 . A plurality of LED chips 500 and a scattering plate 600 are all disposed on the flat heat sink 400 . By directly disposing the LED chip 500 on the flat heat sink 400, the heat dissipation effect is better, which can satisfy the use of high-power LED lamps. In addition, compared with the traditional LED lamps, it is necessary to add a cooling device to the housing, the flat radiator 400 of the LED lamp 20 of the above-mentioned flat radiator can be directly used as a housing, and has excellent heat conduction and heat dissipation effects, making the Less difficult and less expensive.

[0038] see Figure 3 to Figure 5 , which is figure 2 The shown structural schematic diagrams of the flat heat sink 400 in three different directions. The flat heat sink 400 includes several heat con...

Embodiment 2

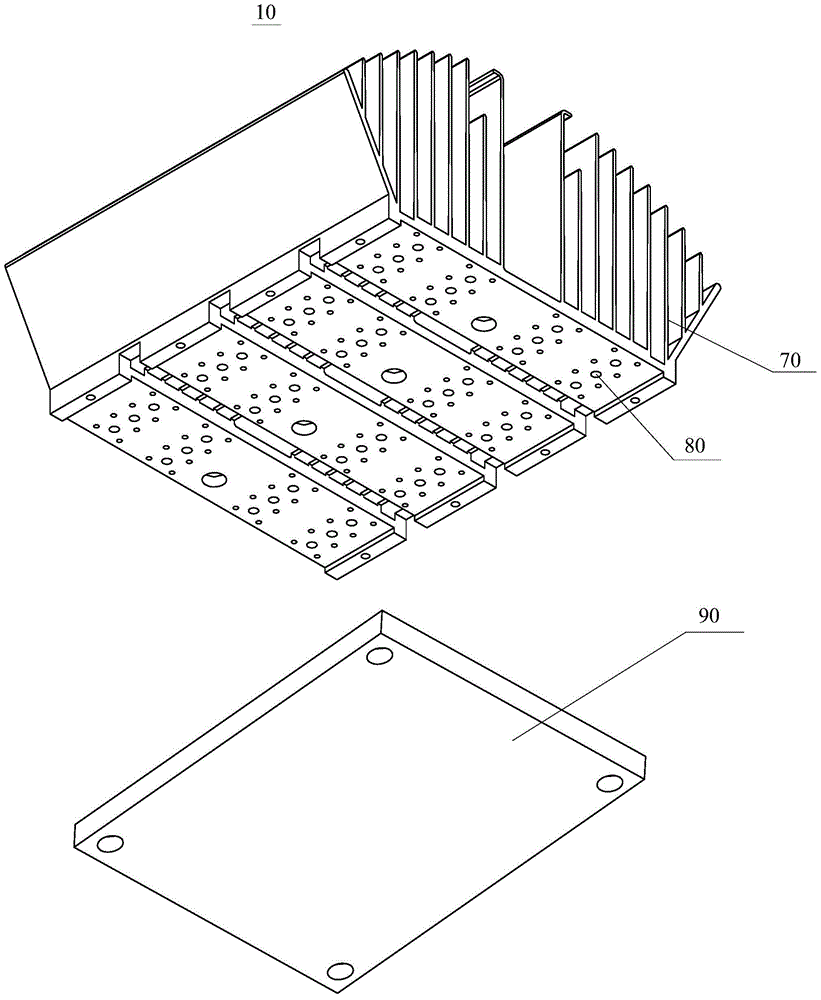

[0055] see Figure 6 and Figure 7 , an LED lamp 30 with a plate heat sink, which includes a plate heat sink 700 , several LED chips 800 and a diffusion plate 900 . A plurality of LED chips 800 and a scattering plate 900 are all disposed on the plate heat sink 700 . By directly disposing the LED chip 800 on the plate radiator 700, the heat dissipation effect is better, which can satisfy the use of high-power LED lamps. In addition, compared with the traditional LED lamps, it is necessary to add a cooling device to the shell. The plate radiator 700 of the LED lamp 30 of the above-mentioned plate radiator can be used directly as a shell, and has excellent heat conduction and heat dissipation effects, and is more difficult to manufacture. Low, lower cost.

[0056] see Figure 6 , the plate radiator 700 includes an aluminum substrate 710 , two cooling fins 720 , several fixed cooling columns 730 , several main cooling columns 740 and several auxiliary cooling columns 750 . Th...

Embodiment 3

[0076] see Figure 9 , the LED lamp 50 with a plate heat sink includes a heat sink 100 , several LED chips 200 and a diffusion plate 300 . Several LED chips 200 and the diffusion plate 300 are all disposed on the heat sink 100 . By directly disposing the LED chip 200 on the heat sink 100, the heat dissipation effect is better, which can satisfy the use of high-power LED lamps. In addition, compared with traditional LED lamps, it is necessary to add a cooling device to the housing. The heat sink 100 of the above-mentioned LED lamp 20 can be directly used as a housing, and has excellent heat conduction and heat dissipation effects, and is less difficult to manufacture. lower cost

[0077] see Figure 9 The heat sink 100 includes several substrates 110 , two heat dissipation fins 120 , two fixed heat dissipation fins 130 , several main heat dissipation fins 140 and several auxiliary heat dissipation fins 150 . The heat dissipation fins 120 , the fixed heat dissipation fins 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com