Instruction self-inspection method for improving reliability of electronic time fuse

A technology of reliability and instruction, applied in fuzes, weapon accessories, offensive equipment, etc., can solve problems such as the inability to reflect the working status of fuzes, and achieve the effect of high reliability, widespread promotion, and solving limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

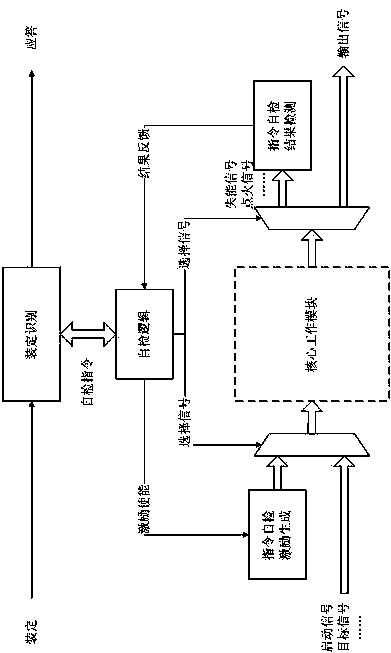

[0021] The method block diagram of command self-test is as follows: figure 1 shown. The instruction self-inspection method is mainly realized by several modules such as a setting recognition module, a self-inspection logic module, an instruction self-inspection incentive generation module, and an instruction self-inspection result detection module. Firstly, add the design operation instruction - self-inspection instruction in the setting instruction set; when the setting identification module receives the self-inspection command, it will send it to the self-inspection logic module after identification, and the self-inspection logic module will enable the instruction self-inspection incentive ge...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap