Method and device for shooting images of inner and outer walls of circular-hole workpiece

A technology of image capture, inner and outer walls, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems that need to be further improved, the detection results are affected by artificial factors, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

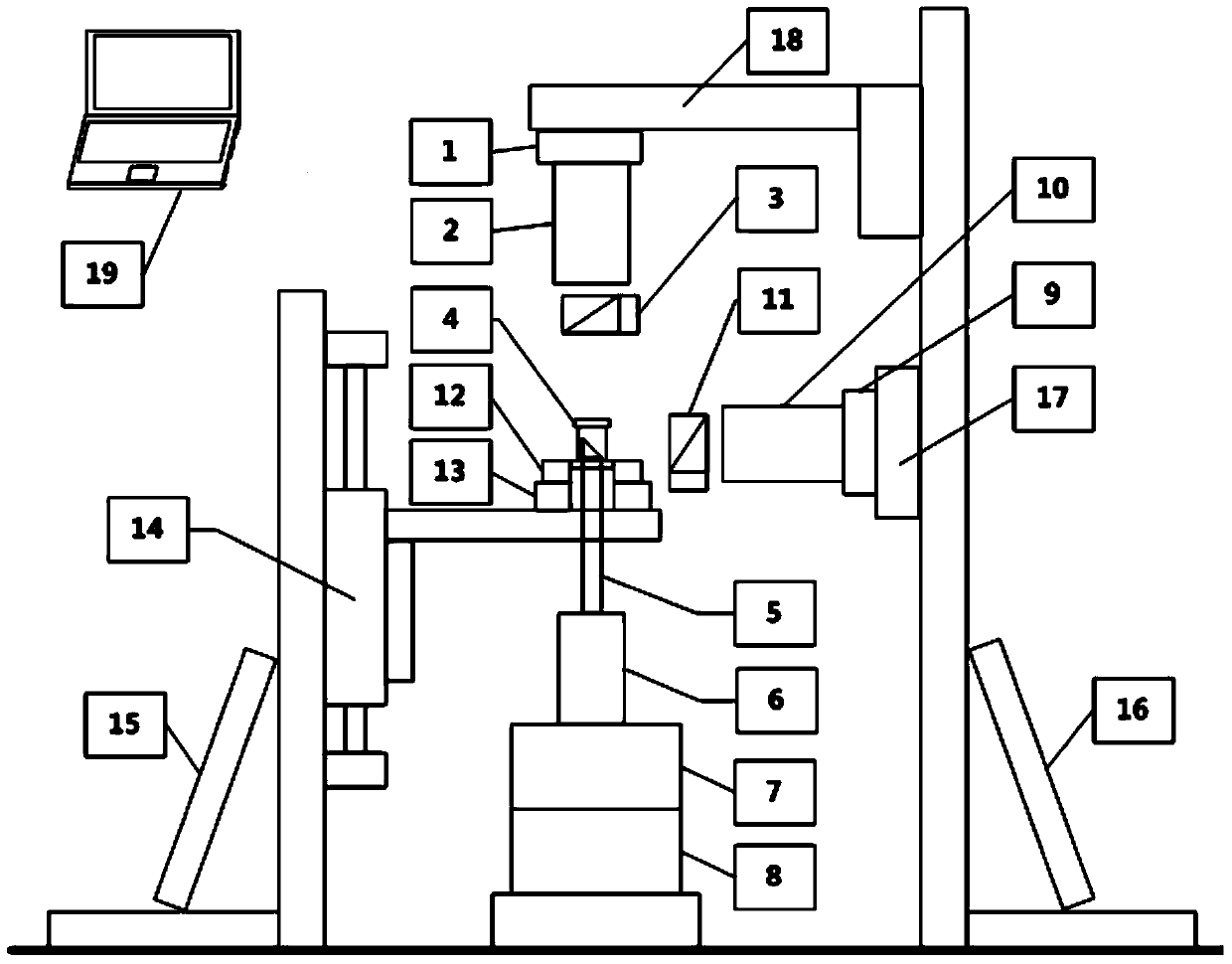

[0044] This embodiment provides a device for taking images of the inner and outer walls of a circular hole workpiece, and the structural schematic diagram of the device is as follows figure 1 As shown, it includes: inner wall camera 1, inner wall telecentric lens 2, inner wall light source 3, round hole workpiece 4, plane mirror 5, mirror sleeve 6, manual horizontal rotary table 7, manual XY sliding table 8, outer wall camera 9 , outer wall telecentric lens 10, outer wall light source 11, workpiece fixture 12, rotary motion platform 13, linear motion platform 14, motor support 15, visual system support 16, outer wall camera support 17, inner wall camera support 18 and processor 19.

[0045] In practical applications, the above-mentioned inner wall CCD camera 1 and outer wall CCD camera 9 may be CCD (Charge-coupled Device, charge-coupled device) cameras or digital cameras. The above-mentioned plane reflector 5 may be a plane reflector with an inclination, such as a 45-degree pl...

Embodiment 2

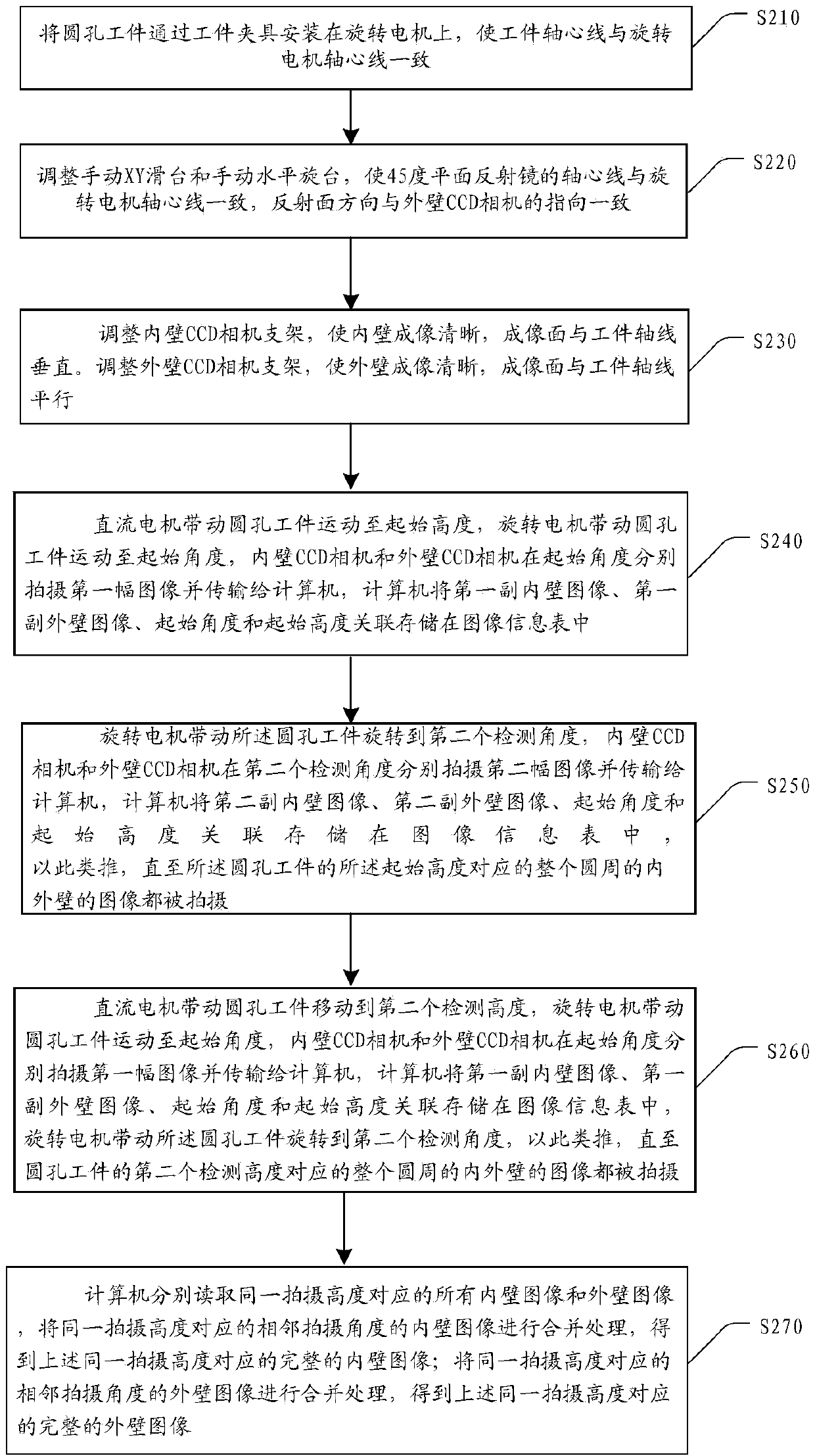

[0074] based on figure 1 As shown in the device for capturing images of the inner and outer walls of a circular hole workpiece, the processing flow of a method for capturing images of the inner and outer walls of a circular hole workpiece provided by this embodiment is as follows figure 2 As shown, the following processing steps are included:

[0075] Step S210 , installing the workpiece with the round hole on the rotary motion platform through the workpiece fixture, so that the axis line of the workpiece coincides with the axis line of the rotary motion platform.

[0076] Step S220, adjust the manual XY slide table so that the axis line of the 45-degree plane mirror is consistent with the axis line of the rotary motion platform; adjust the manual horizontal rotation table so that the direction of the reflection surface of the 45-degree plane mirror is in line with the direction of the CCD camera on the outer wall Consistent, that is, parallel to the axis of the circular hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com