System and method for adjusting common optical axis of off-axis optical system

An optical system and adjustment system technology, applied in optics, optical components, installation, etc., can solve the problems of low adjustment accuracy and complicated process of the common optical axis, and achieve the effect of convenient adjustment of the common optical axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

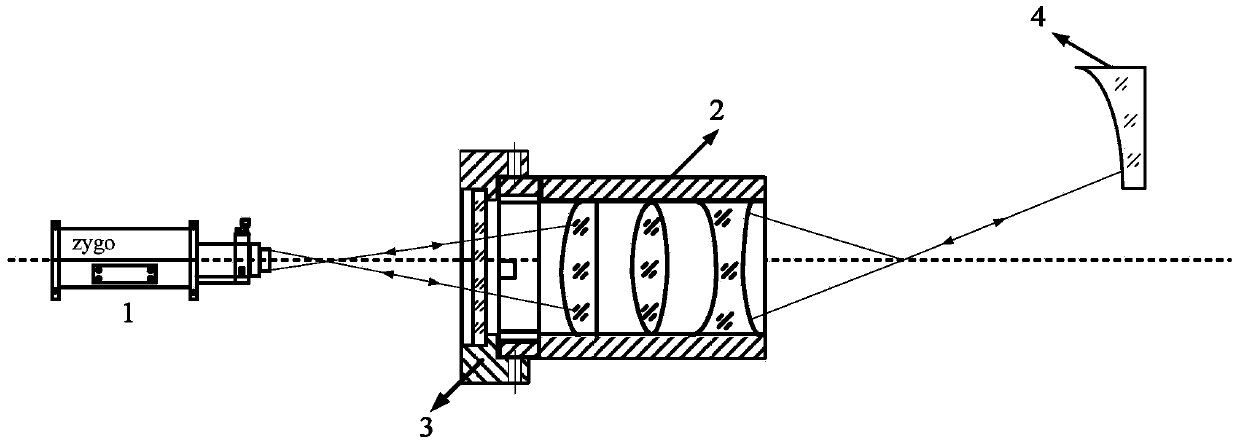

[0033] The invention provides an adjustment system for realizing the common optical axis of the off-axis optical system. The adjustment system for realizing the common optical axis of the off-axis optical system includes an interferometer 1, a compensator optical system 2, a cross reticle assembly and a plane reflector 5. The cross reticle assembly is set at the end of the compensator optical system 2; the interferometer 1, the cross reticle assembly, the compensator optical system 2 and the plane mirror 5 are sequentially arranged on the same optical path.

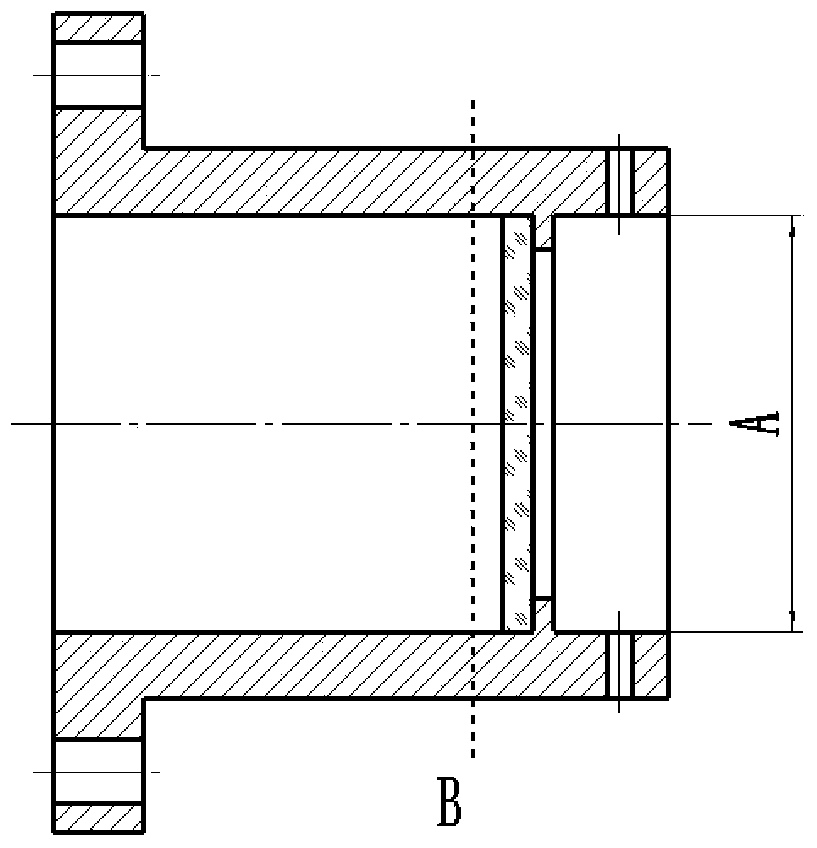

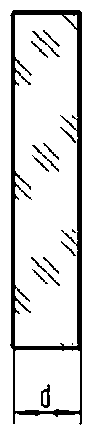

[0034] In order to accurately calibrate the optical axis of the compensator, a cross reticle fixture 3 is designed. Cross reticle tooling 3 is a cross reticle assembly processed through optical centering, its structure diagram is shown in figure 2 As shown, the cross reticle is as image 3 as well as Figure 4 shown. exist figure 2 Among them, A represents the size of the inner circle of the tooling frame, and surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com