Folded scanning optical system based on mems micromirror

An optical system and folding technology, applied in the field of optics, can solve the problem of small scanning field of view and achieve the effect of small spot, large scanning field of view and fast scanning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

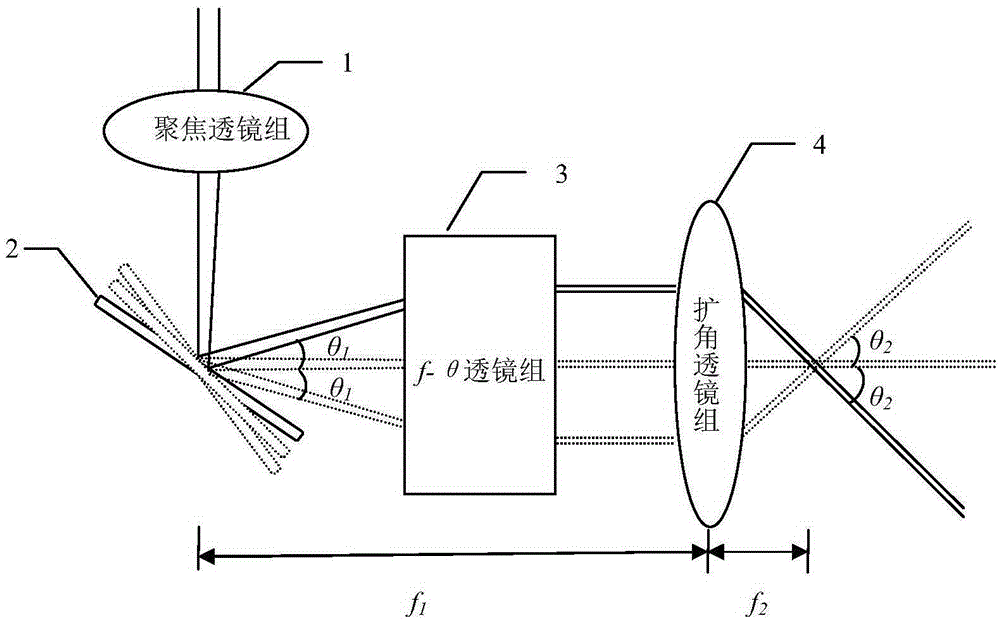

[0024] Specific implementation mode one: see figure 1 Illustrate this embodiment, the MEMS micromirror folding type scanning optical system based on this embodiment, it comprises focusing lens group 1, MEMS micromirror 2, f-θ lens group 3 and angle-expanding lens group 4;

[0025] After the incident light is transmitted by the focusing lens group 1, and then reflected by the MEMS micromirror 2, it enters the f-θ lens group 3, and after being transmitted by the f-θ lens group 3, it enters the angle-expanding lens group 4, and passes through the angle-expanding lens The angle between the transmitted light of group 4 and the optical axis of the system is θ 2 ,and f 2 less than f 1 ;

[0026] Among them, θ 1 is the angle between the light reflected by the MEMS micromirror 2 and the optical axis of the system, f 2 Indicates the effective image square focal length of the expander lens group, f 1 Indicates the focal length of the f-θ lens group 3;

[0027] The mechanical def...

specific Embodiment approach 2

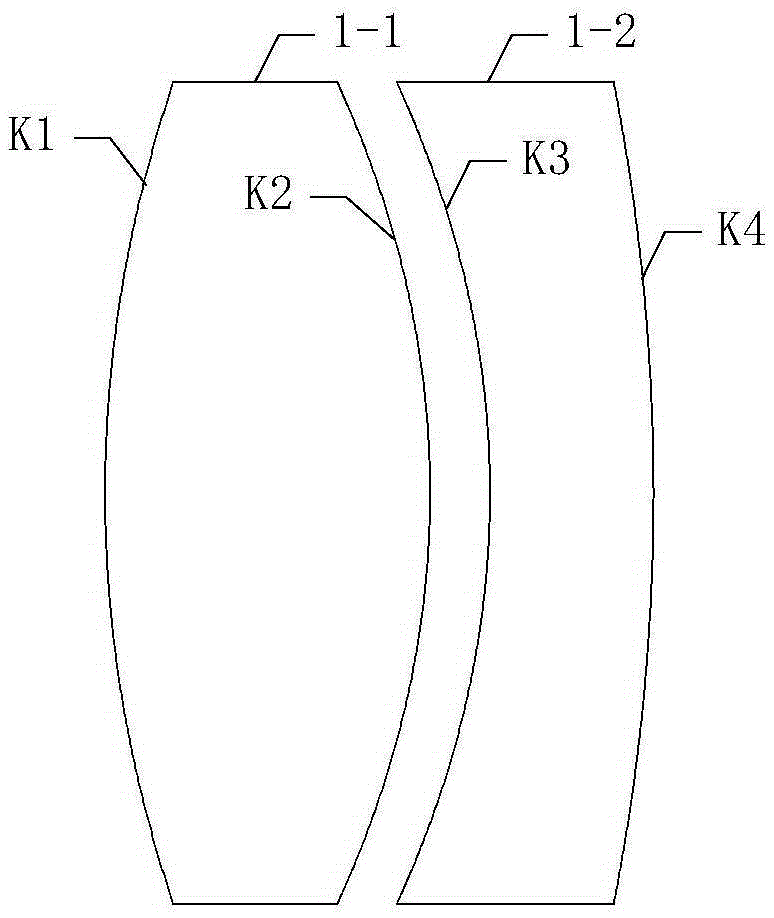

[0039] Specific implementation mode two: see figure 1 and 2 Describe this embodiment, the difference between this embodiment and the MEMS micromirror folded scanning optical system described in the first embodiment is that the focusing lens group 1 is a two-piece front positive lens group, and the two-piece The front positive lens group includes a coaxial No. 1 convex lens 1-1 and a No. 1 concave lens 1-2, and the incident surface of the No. 1 convex lens 1-1 is the incident surface of the two-piece front positive lens group. The materials of the No. 1 convex lens 1-1 and the No. 1 concave lens 1-2 are different, and both are suitable for laser with a wavelength of 1550nm.

[0040] In this embodiment, as figure 2 As shown, the focusing lens group composed of the No. 1 convex lens 1-1 and the No. 1 concave lens 1-2 in front of the MEMS, the focal length of the focusing lens group 1 can be designed to be 100 mm. It consists of two different infrared refractive index material...

specific Embodiment approach 3

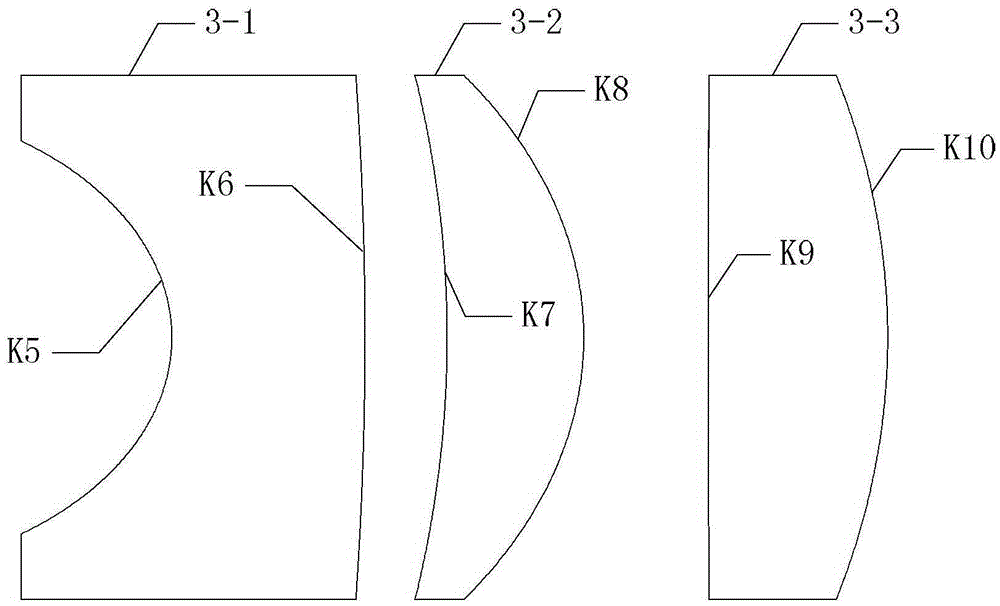

[0041] Specific implementation mode three: see figure 1 and 3 Describe this embodiment, the difference between this embodiment and the MEMS micromirror folded scanning optical system described in the second embodiment is that the f-θ lens group 3 is a three-piece f-θ lens, and the The three-piece f-θ lens comprises three coaxial lenses, and the three coaxial lenses are sequentially No. 2 concave lens 3-1, No. 2 convex lens 3-2, No. 3 convex lens 3-3, and 2 The incident surface of No. concave lens 3-1 is the incident surface of f-θ lens group 3.

[0042] In this embodiment, as image 3As shown, the three-piece f-theta lens is composed of three lenses, and the best focal length of the three-piece f-theta lens is 100mm. The three lenses are successively No. 2 concave lens 3-1, No. 2 convex lens 3-2, and No. 3 convex lens 3-3, and their materials are respectively fused silica glass F_SILICA, SF18, and SF18. The lens curve of No. 2 concave lens 3-1 towards the incident beam sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com