Crystal light-emitting SMD LED lamp bead and preparation method thereof

A technology of LED lamp beads and crystal light emitting, which is applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., and can solve the problem of color consistency of LED patch lamp beads and unsatisfactory spot effects, uneven mixing of phosphor powder and silica gel, and fluorescent Inconsistency in powder precipitation and other problems, to achieve the effect of protecting the gold wire structure inside the LED, reducing the process of light and color separation, and good color consistency in batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

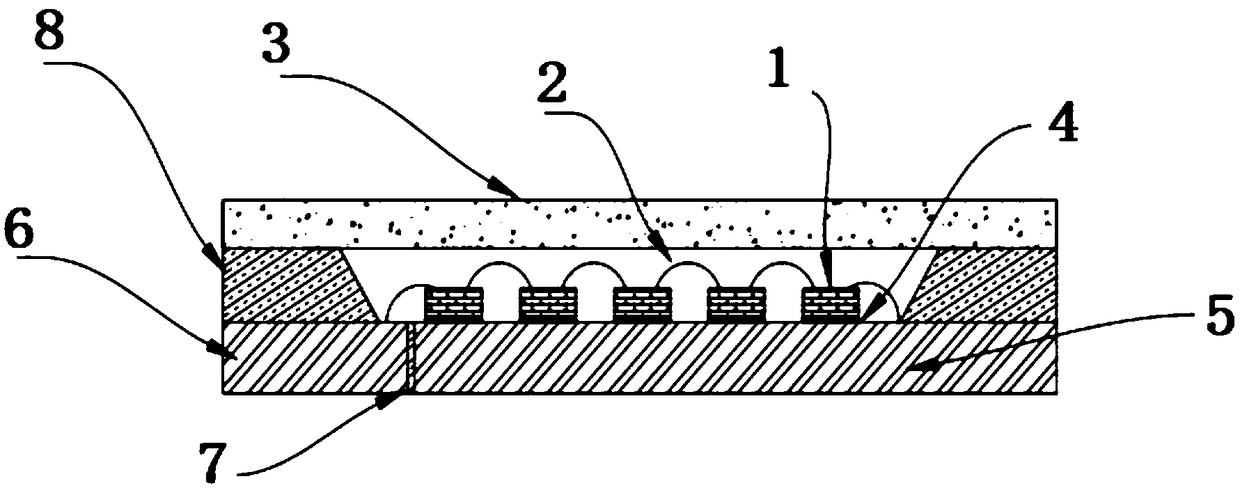

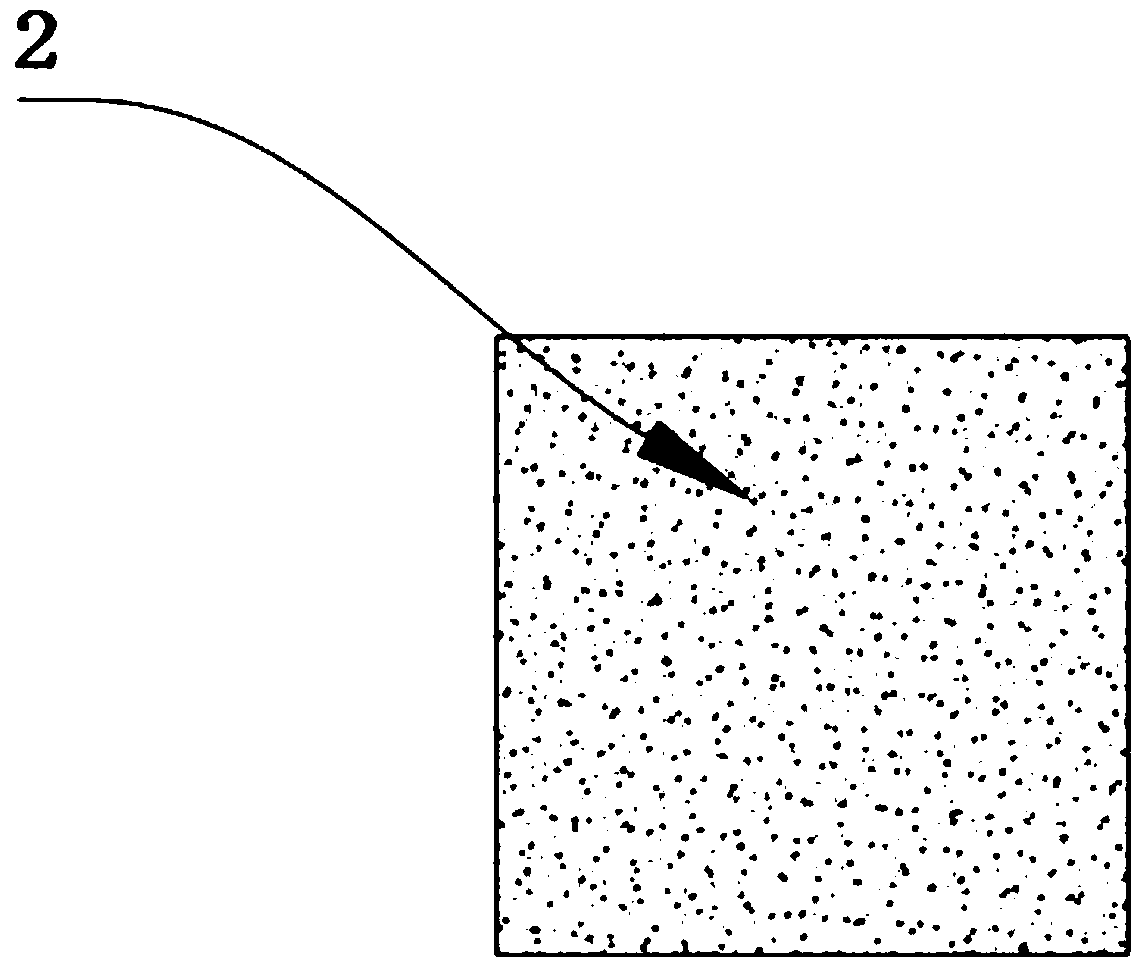

[0021] In this example, if figure 1 , figure 2 As shown, the present invention provides a crystal light-emitting patch LED lamp bead, which includes an LED chip 1, a gold wire 2, a crystal sheet 3 and a bracket, and the gold wire 2 is a conductive wire. The bracket adopts a cup-shaped structure, and the LED chips 1 are arranged at intervals inside the cup-shaped structure of the bracket through the crystal-bonding glue 4. Each LED chip 1 is connected in series through the gold wire 2, and one end of the outermost LED chip 1 is connected to the bracket through the gold wire 2. The other end of the LED chip 1 is connected to the adjacent LED chip 1 via a gold wire. A crystal sheet 3 is arranged on the top of the cup-shaped structure of the bracket, and the LED chip 1 is enclosed in the bracket by the crystal sheet 3 to form an LED lamp bead.

[0022] In the above embodiment, the support includes a conductive positive electrode 5 , a conductive negative electrode 6 , an insula...

Embodiment 2

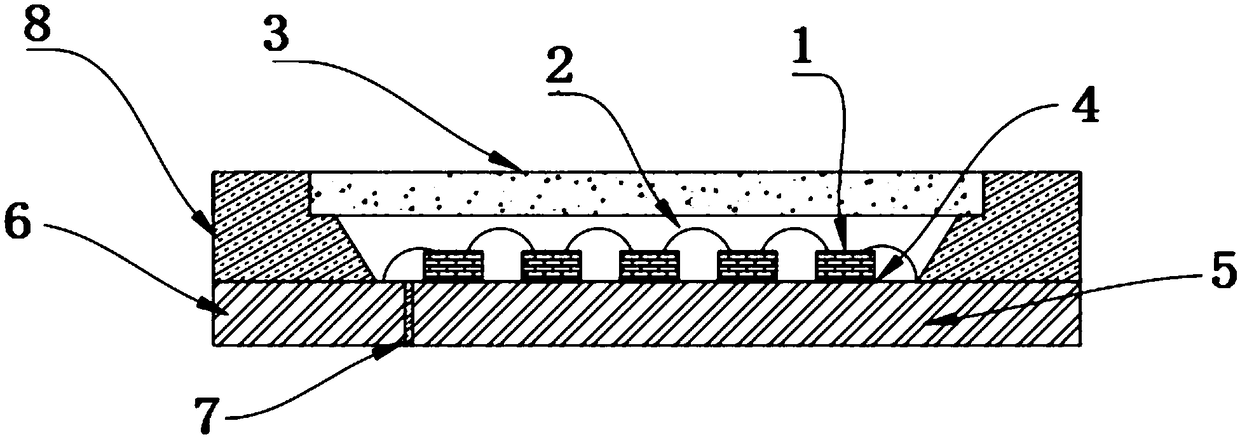

[0026] Such as image 3 , Figure 4 As shown, the structure of the crystal light-emitting patch LED lamp bead provided in this embodiment is basically the same as that in Embodiment 1. The difference is that in this embodiment, the inner wall of the top of the reflector cup 8 of the bracket is provided with a groove. The crystal piece 3 is embedded in the groove, so that the upper surface of the crystal piece 3 and the upper surface of the bracket are located at the same horizontal line.

[0027] In the above-mentioned embodiments, the crystal plate 3 adopts the structure of the crystal plate in the authorized announcement number CN106270523B.

[0028] The present invention also provides a method for preparing a crystal light-emitting patch LED lamp bead, which includes the following steps:

[0029] 1) Fix the LED chip 1 on the bottom of the reflective cup 8 with crystal bonding glue 4 in the reflective cup 8 of the bracket through a crystal bonder; wherein, the size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com