AlGaInP red light-emitting diode device structure with composite reflector

A compound mirror and red light-emitting technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of sacrificing the reflectivity of the mirror layer, the light output efficiency of the device, and insufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

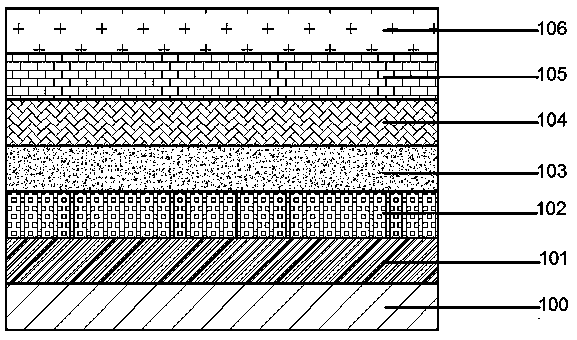

[0040] 1. Epitaxial growth: First, on the GaAs substrate 100, a GaInP etch stop layer 101, a GaAs ohmic contact layer 102, an n-type AlGaInP main layer 103, an active layer 104, a p-type AlGaInP main layer 105, and a p-type GaP ohmic contact are sequentially grown on the GaAs substrate 100. Layer 106, such as figure 1 shown;

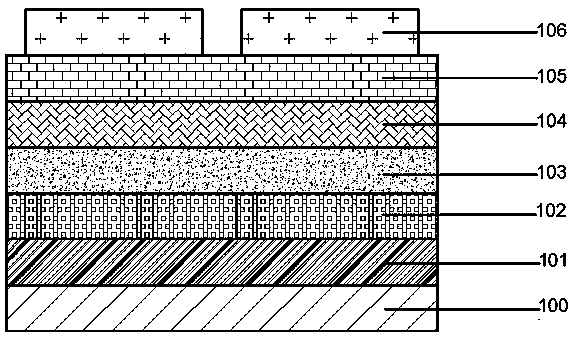

[0041]2. Current blocking photolithography: etching the p-type GaP ohmic contact layer 106 in the area directly under the edge and the designed n-electrode 113 to expose the p-type AlGaInP main layer 105, such as figure 2 As shown, the remaining thickness of the p-type semiconductor layer is 0.5 μm-2.5 μm, and the doping concentration of the p-type AlGaInP main layer 105 exposed after etching is less than 1×10 19 / cm 3 ;

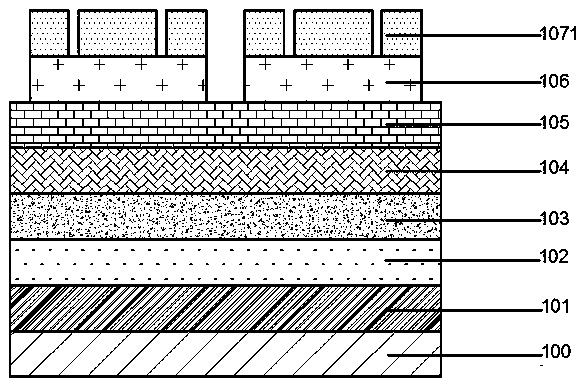

[0042] 3. Preparation of dielectric layer 1071: grow a layer of SiO by plasma-assisted chemical vapor deposition (PECVD) 2 The dielectric layer 1071 as the composite mirror layer has a thickness of 50-500 nm; in the reserved area ...

Embodiment 2

[0048] 1. Epitaxial growth: First, on the GaAs substrate 100, a GaInP etch stop layer 101, a GaAs ohmic contact layer 102, an n-type AlGaInP main layer 103, an active layer 104, a p-type AlGaInP main layer 105, and a p-type GaP ohmic contact are sequentially grown on the GaAs substrate 100. Layer 106, such as figure 1 shown.

[0049] 2. Current blocking lithography: etching the p-type GaP ohmic contact layer 106 at the edge and the area directly under the designed n-electrode 113 to expose the p-type AlGaInP main layer 105. After etching, the remaining thickness of the p-type semiconductor layer is 0.5μm-2.5μm, such as figure 2 shown;

[0050] 3. Preparation of the dielectric layer 1071: a layer of SiO is grown on the p-type GaP ohmic contact layer 106 by PECVD 2 The dielectric layer 1071 as a composite mirror layer has a thickness of 90 nm-120 nm; in the reserved area of the p-type GaP ohmic contact layer 106, SiO 2 A round hole is photoetched to expose the p-type GaP ...

Embodiment 3

[0057] 1. Epitaxial growth: First, on the GaAs substrate 100, a GaInP etch stop layer 101, an n-type GaAs ohmic contact layer 102, an n-type AlGaInP main layer 103, an active layer 104, a p-type AlGaInP main layer 105, and a p-type GaP are sequentially grown on the GaAs substrate 100 ohmic contact layer 106, such as figure 1 shown;

[0058] 2. The first transfer: the wafer is transferred to the temporary substrate 116 with wax or other easily removable materials 115; the temporary substrate 116 is sapphire or silicon or other materials that can provide support, such as Figure 11 shown;

[0059] 3. Remove the substrate and cut-off layer: use NH 3 .H 2 O:H 2 o 2 =1:3 or other concentrations that can corrode the GaAs substrate 100, remove the GaAs substrate 100, the temperature is 20-30°C, and the time is 20 min-60 min; use HCl:H3PO4=2:1, remove the GaInP etch stop layer 101 , the temperature is 20-30°C, the time is 1 min-5 min, such as Figure 12 shown;

[0060] 4. Alig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com