Charging machine for fly maggot large-scale faming

A feeder and fly maggot technology, applied in transportation and packaging, loading/unloading, animal husbandry, etc., can solve the problems of high labor intensity, time-consuming and laborious, and poor working environment for workers, so as to reduce labor intensity of workers and improve feeding. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

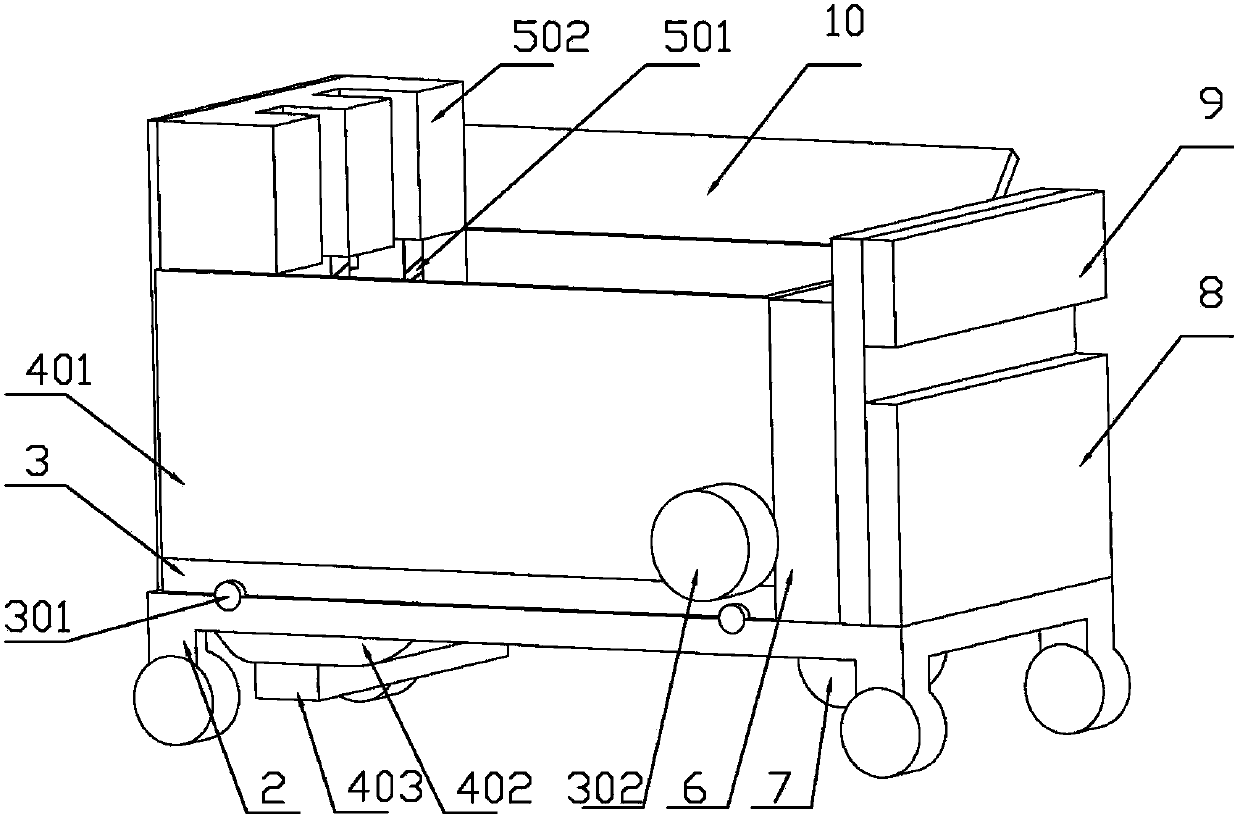

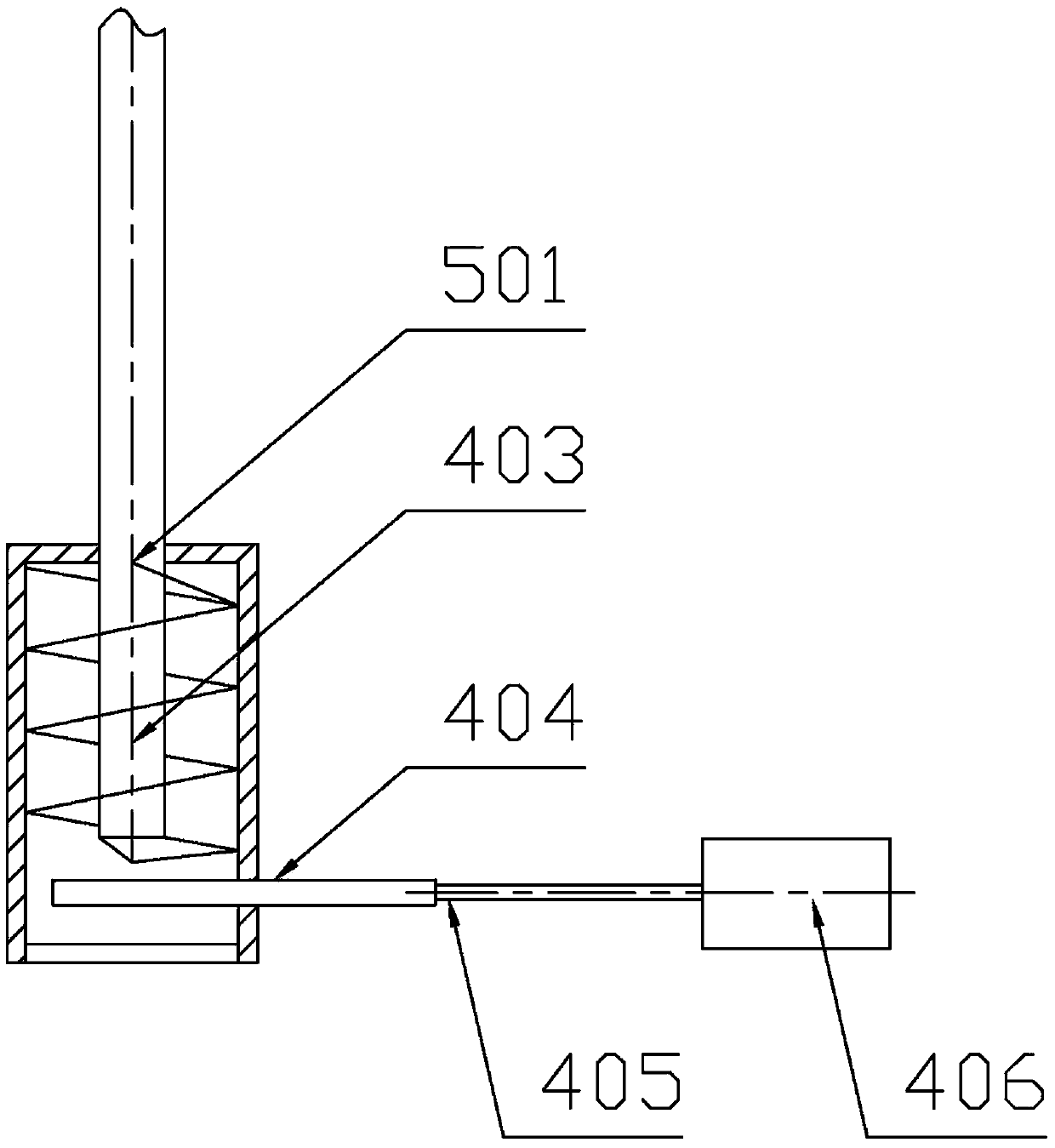

[0022] See figure 1 , a feeder, the feeder includes a track and a rail car 2 moving on the track, the rail car 2 is provided with a mobile platform 3 that can move perpendicular to the direction of movement of the rail car, and the mobile platform 3 is provided with There is a mounting hole, a hopper 401 is detachably plugged into the mounting hole, at least one sub-hopper 402 is connected to the lower bottom of the hopper 401, and a material nozzle 403 is detachably connected to the sub-hopper 402, and the material A feeding mechanism is coaxially provided in the mouth 403 . According to different installation methods of the nozzle 403, the connection and installation positions of the feeding mechanism and the rail car are different. For details, see Embodiment 2 and Embodiment 3

Embodiment 2

[0022] See figure 1 , a feeder, the feeder includes a track and a rail car 2 moving on the track, the rail car 2 is provided with a mobile platform 3 that can move perpendicular to the direction of movement of the rail car, and the mobile platform 3 is provided with There is a mounting hole, a hopper 401 is detachably plugged into the mounting hole, at least one sub-hopper 402 is connected to the lower bottom of the hopper 401, and a material nozzle 403 is detachably connected to the sub-hopper 402, and the material A feeding mechanism is coaxially provided in the mouth 403 . According to different installation methods of the nozzle 403, the connection and installation positions of the feeding mechanism and the rail car are different. For details, see Embodiment 2 and Embodiment 3

[0023] See figure 1 , the rail car 2 is also provided with a control device 6 . The control device 6 is used to control the operation of the whole rail car.

[0024] See figure 1 The bottom of...

Embodiment 3

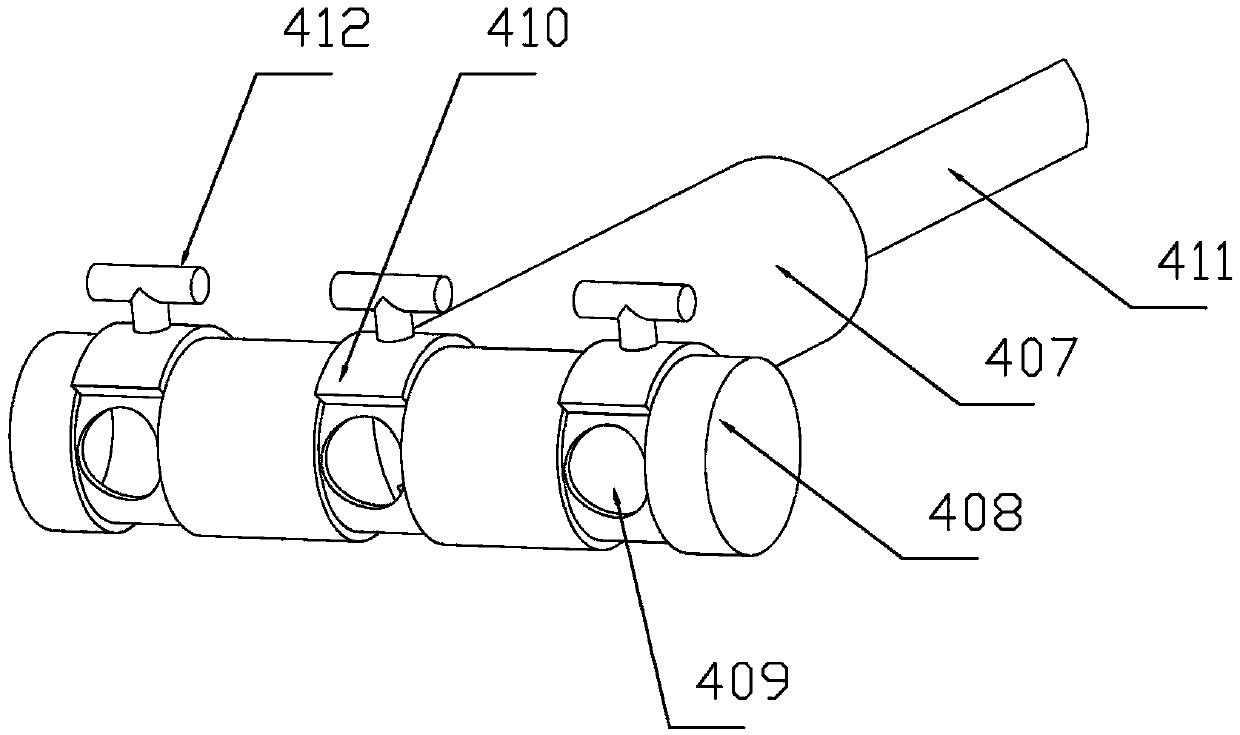

[0033] See figure 1 and Figure 4 , the other structures of the feeder are the same as in Embodiment 1, only the installation positions of the feed nozzle and the corresponding feeding mechanism are different, and the second feed nozzle includes a connector 412 and a corrugated bendable 360-degree bendable corrugated joint connected to it. The hose 413 is also inserted with an auger (not shown in the figure) in the connector 412 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com