Production process of abelmoschus esculentus(L) Moench scented tea

A technology for making sunflower tea, which is applied in the field of making okra flower tea, can solve the problems of exhaustion, dim color of okra flowers, and influence on sales, so as to reduce the loss of nutrients, reduce the cost, and avoid deterioration and the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

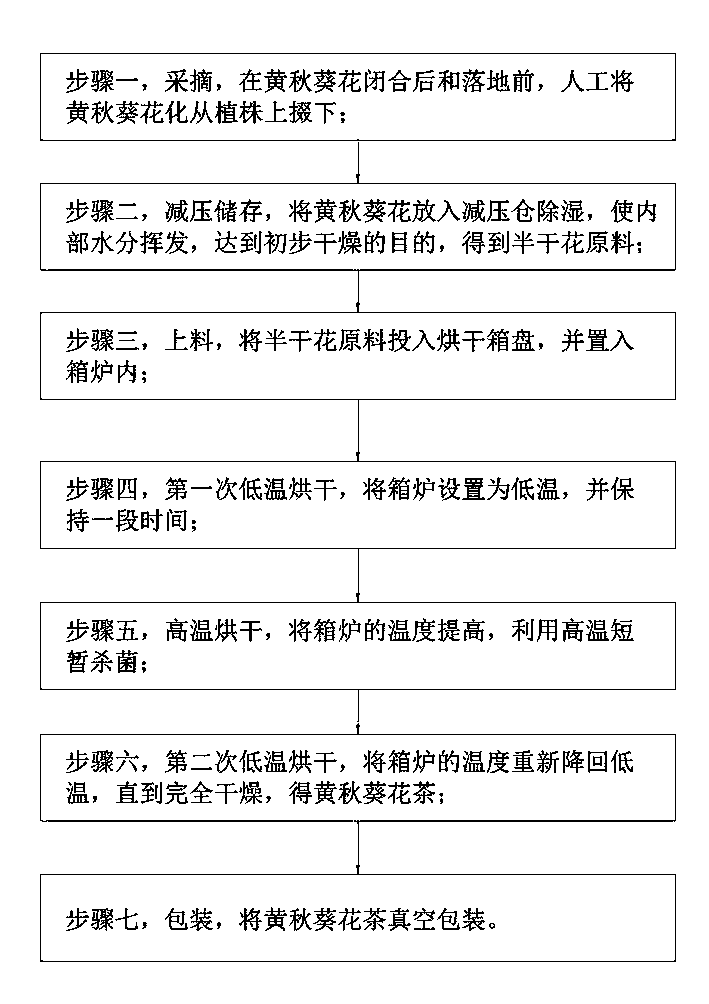

[0024] refer to figure 1 , the preparation technology of okra scented tea provided by the invention comprises the following steps:

[0025] Step 1, picking. After the okra flowers are closed and before they fall to the ground, the okra flowers are artificially removed from the plants;

[0026] Step 2, store under reduced pressure, put the okra flowers into the decompression chamber to dehumidify, so that the internal moisture is volatilized, and the purpose of preliminary drying is achieved, and the semi-dried flower raw material is obtained;

[0027] Step 3, feeding, put the semi-dried flower raw material into the drying box and put it into the box furnace;

[0028] Step 4, the first low-temperature drying, set the oven to low temperature, and keep it for a period of time;

[0029] Step 5, drying at high temperature, increasing the temperature of the box furnace, and using high temperature for short-term sterilization;

[0030] Step 6, drying at low temperature for the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com