A brush roller system for automatic replacement of brush rollers

An automatic replacement and brush roller technology, which is applied to the cleaning of boots and shoes, cleaning equipment, household appliances, etc., to achieve the effect of compact structure, reliable function, and convenient automatic replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

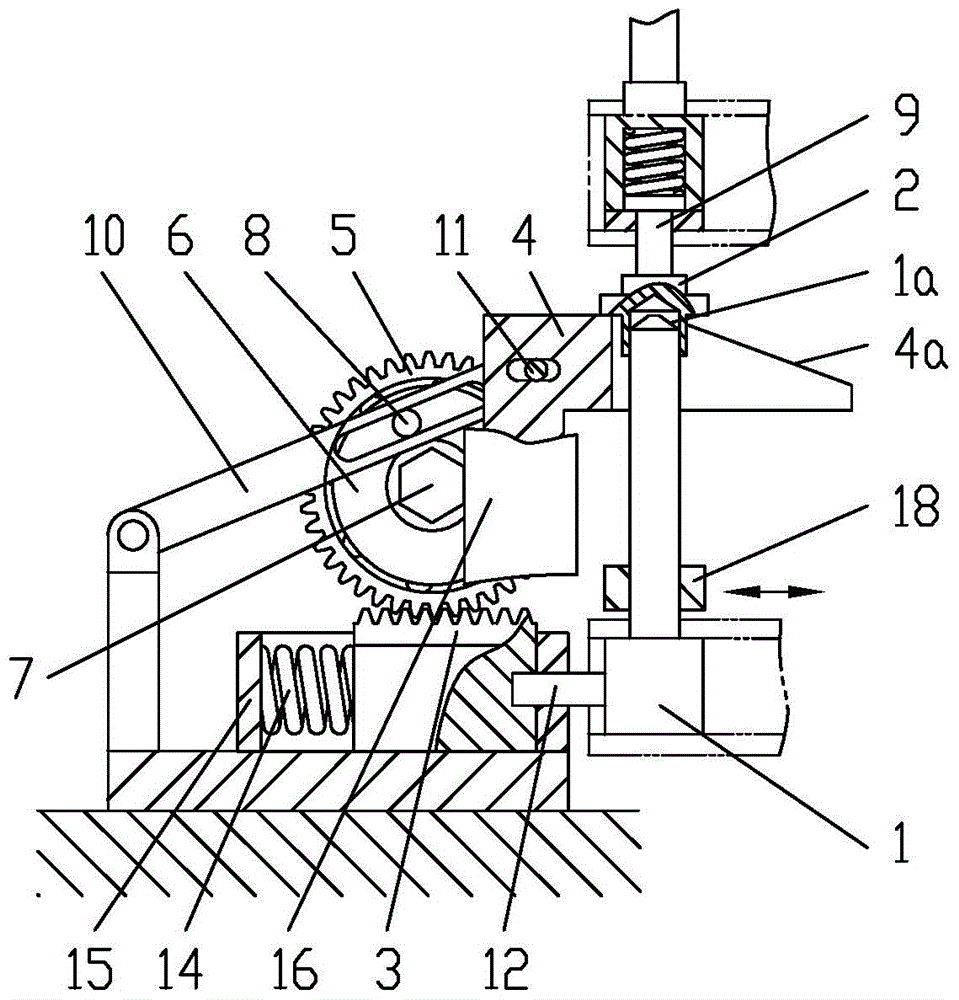

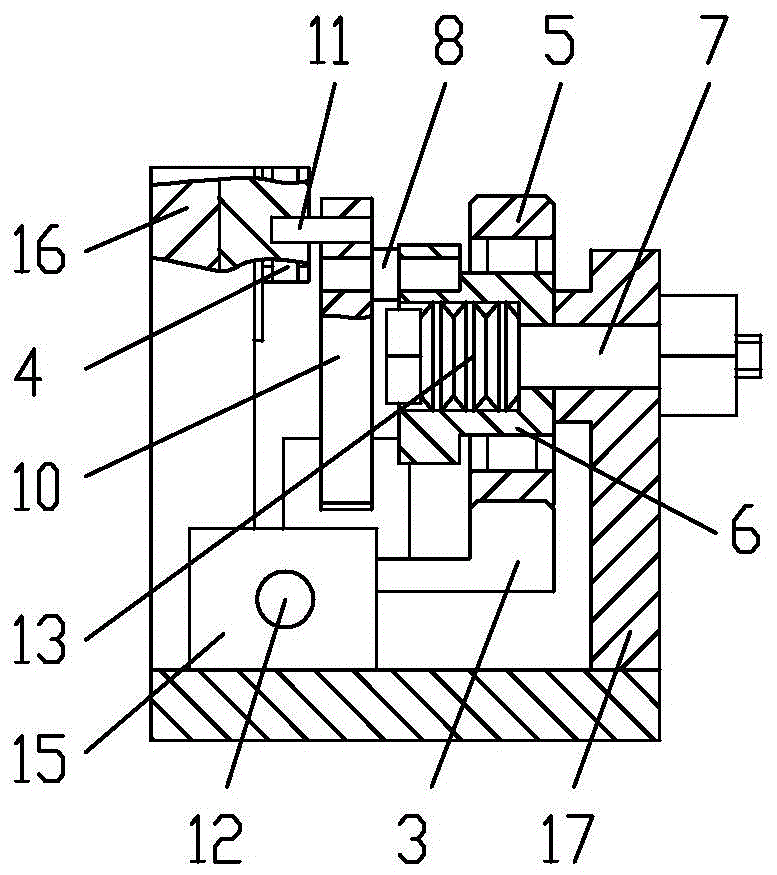

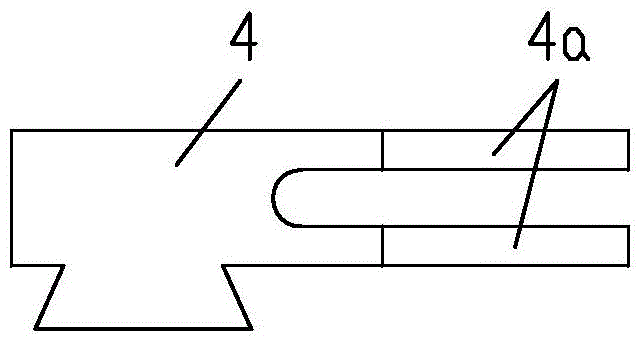

[0020] see figure 1 , figure 2 , image 3 , a brush roller system for automatic replacement of brush rollers for reciprocating brush rollers, including two-stage detachable brush rollers, and a brush roller separation mechanism for brush roller separation; the shoe polisher is equipped with a brush roller The guide groove for the roller to move and guide has a double-layer structure; the brush roller is composed of a brush roller working section and a brush roller connecting section 1, and the brush roller working section includes a supporting body 9, and the lower end of the supporting body 9 is used for rubbing The upper guide groove of the shoe machine is matched, and the lower end of the support body 9 is coaxially connected with the self-resetting telescopic joint 2 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com