Dies for forming machines for wound socket joints

A technology for forming equipment and socket joints, which is applied in the field of molds for winding-type socket joint forming equipment, can solve the problems of large changes in the outer diameter of the mold, errors in socket openings, and large changes in the fixed position of pipes, etc., and achieve small errors, The effect of high stability and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The mold used for forming equipment for winding socket joints according to the present invention will be further described in detail through specific examples below.

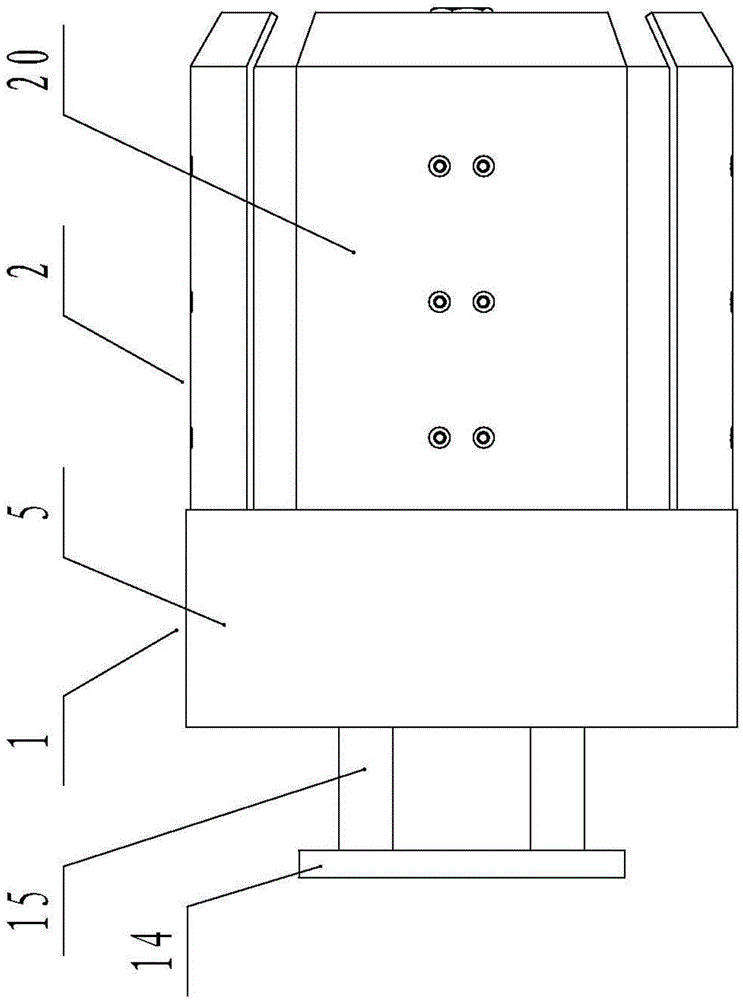

[0017] Such as figure 1 and figure 2 As shown, a mold for winding socket joint forming equipment includes a mold body 1 and a mold clamping part 2 designed in one piece. The outer diameter of the mold body 1 is fixed, and the outer diameter of the mold clamping part 2 can be adjusted. Change, the mold body 1 includes a base 3 and a partition 4 oppositely arranged, a closed ring 5 is arranged between the base 3 and the partition 4, the closed ring 5 connects the outer edge of the base 3 and the partition 4, and the outer wall of the closed ring 5 The mold clamping part 2 made of non-metallic material is arranged on the front end of the base 3, the front end surface of the base 3 is provided with a central shaft 6 perpendicular to the base 3, the front end of the central shaft 6 is provided with a top pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com