Automatic solder paste printing machine

A solder paste printing machine, fully automatic technology, applied to printing machines, rotary printing machines, screen printing machines, etc., can solve problems such as low production efficiency, increased labor intensity, and inability to adjust the pressure of the scraper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention. In the following detailed description, certain exemplary embodiments of the invention are described by way of illustration only. Needless to say, those skilled in the art would realize that the described embodiments can be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims.

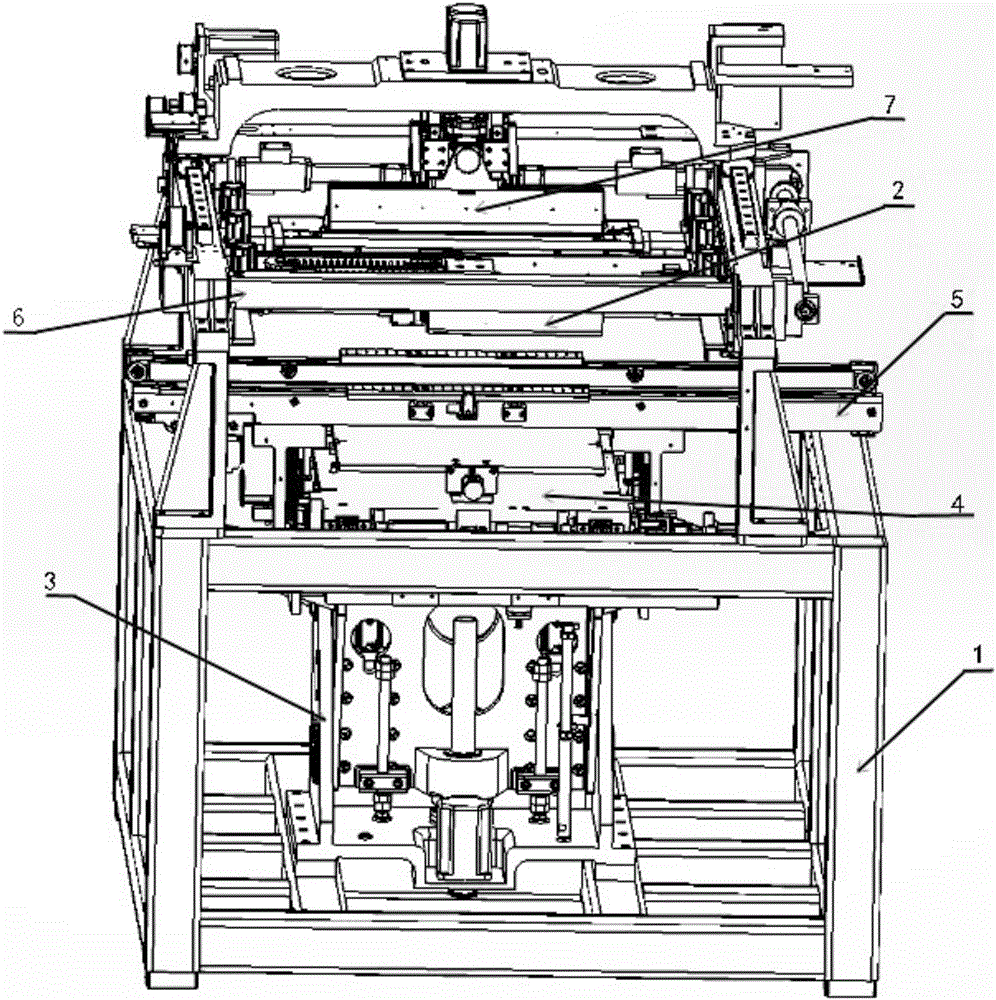

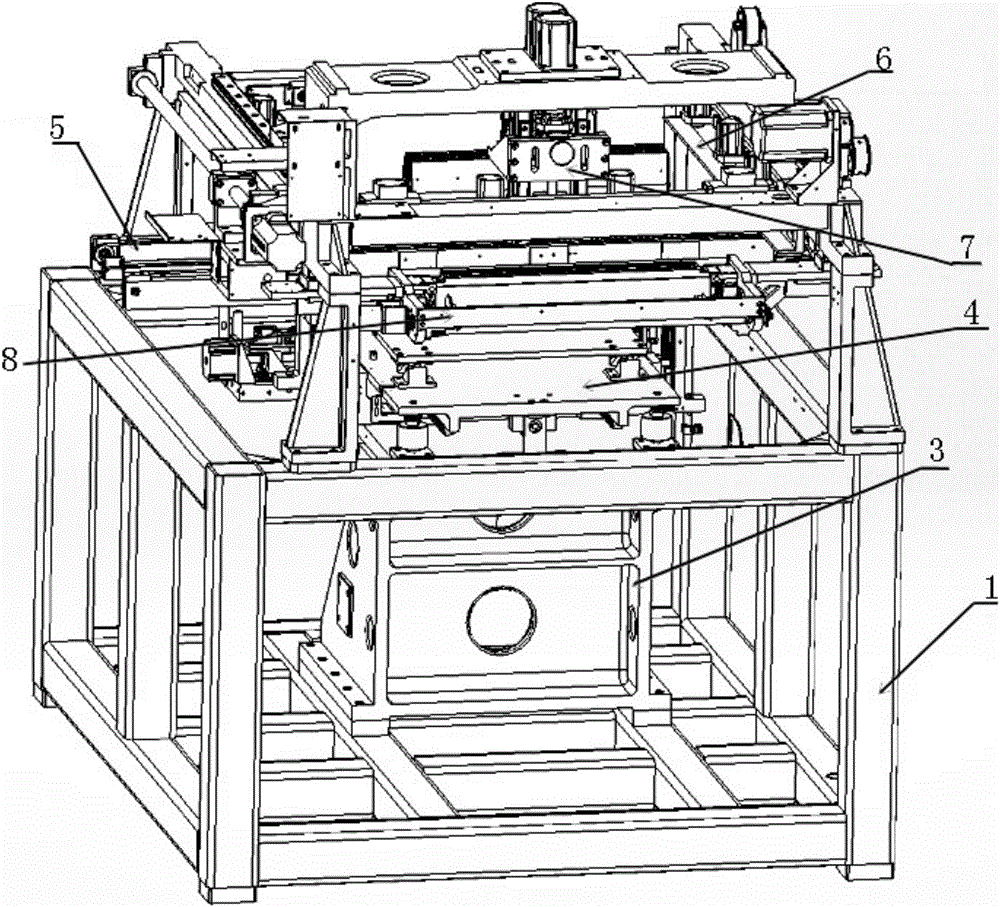

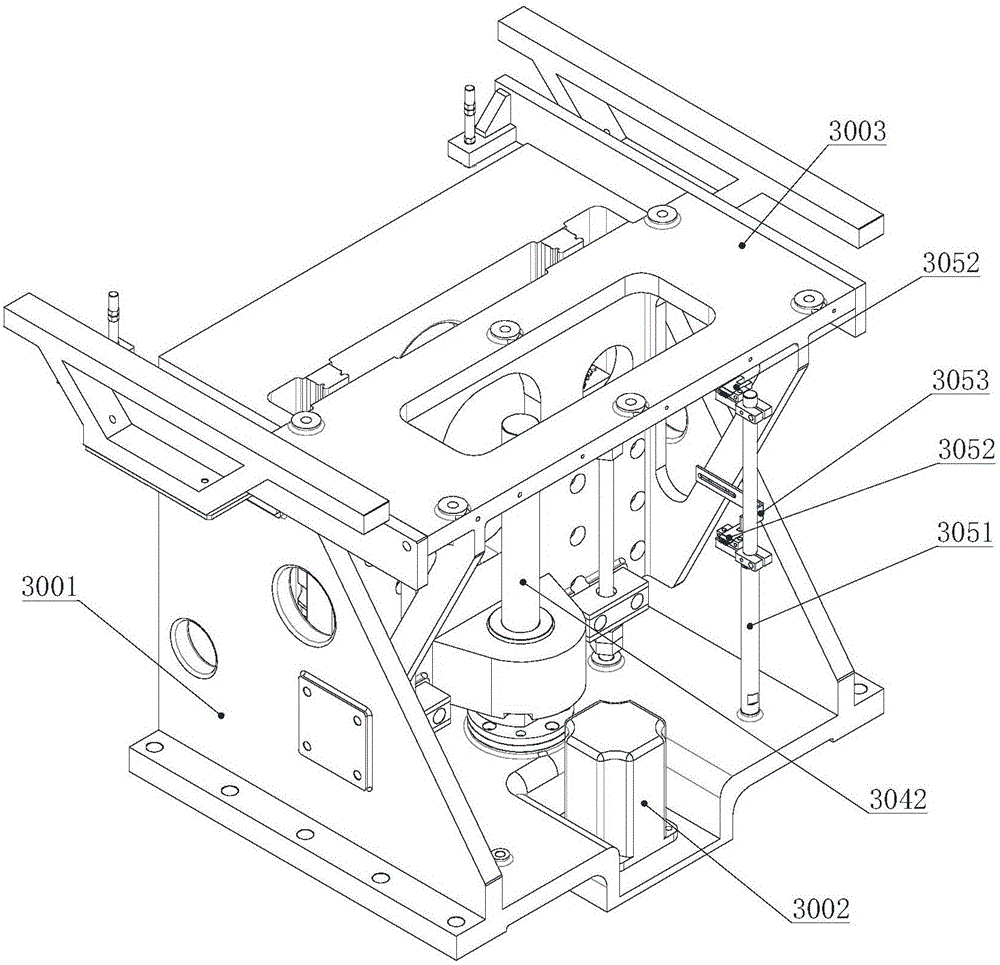

[0066] Such as figure 1 and figure 2 As shown, the fully automatic solder paste printing machine includes a rack unit 1, a Z-axis lifting system 3 is installed at the bottom of the rack unit 1, and a platform correction system 4 is installed at the top of the Z-axis lifting system 3 , a guide rail transport system 5 is installed on the platform correction system 4; a stencil frame clamping system 6, a scraper printing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap