Feeding device with bag insertion function

A feeding device and function technology, applied in the field of packaging machinery, can solve the problems of low production efficiency, inconvenient maintenance, and need to insert bags, etc., and achieve the effects of high production efficiency, simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

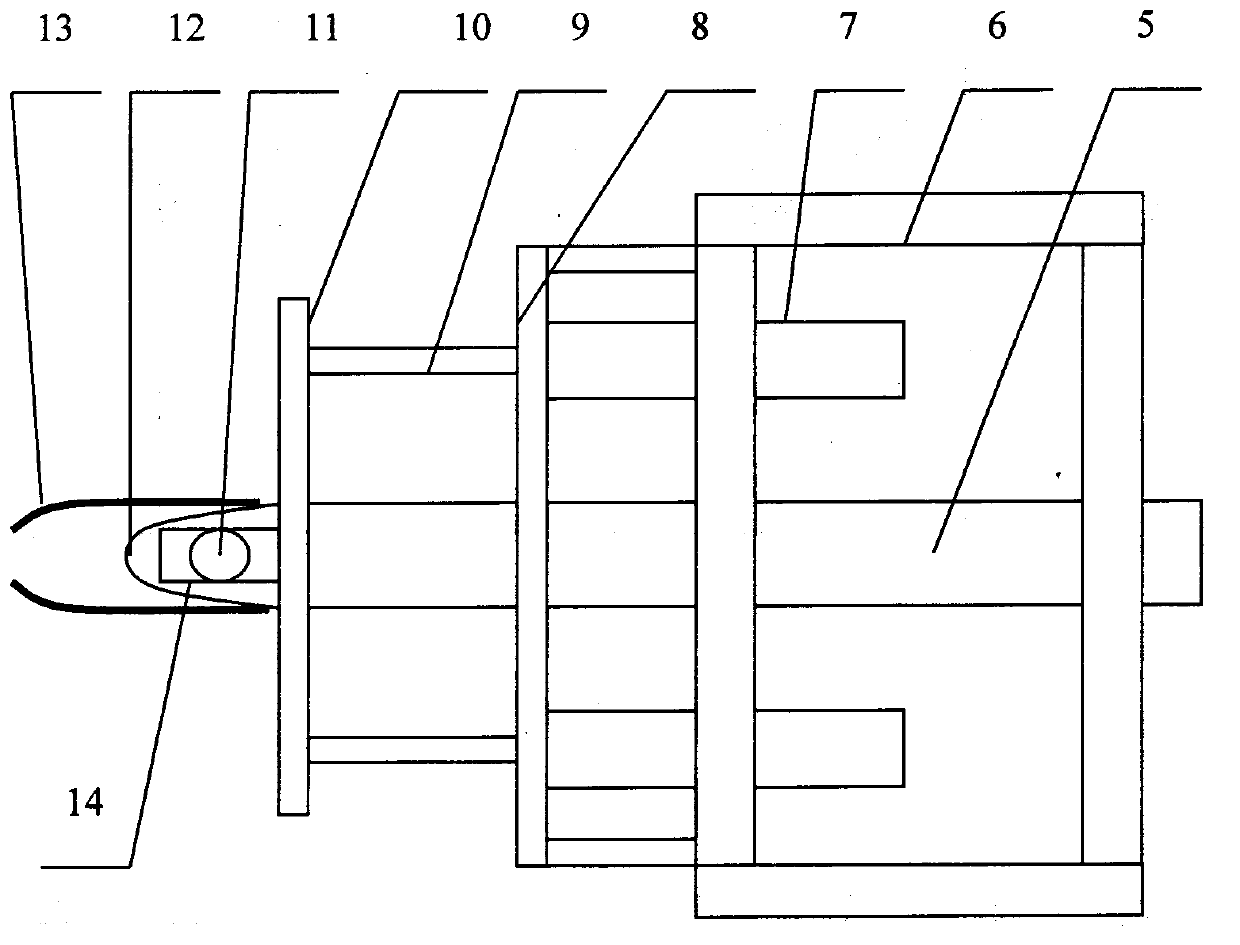

[0030] See figure 2 .

[0031] The feeding device with the bag insertion function generally includes a feeding pipe 5, a frame 6 and a bag grabbing mechanism composed of a push-pull cylinder 7, a movable block 10, and a long mouth. Two push-pull cylinders 7 are fixed on the frame 6, with the fixed block 8 of the frame 6 as a boundary, the movable block 10 connected by two push-pull rods 9 of the two push-pull cylinders 7 can only retreat to the position of the fixed block 8. The movable block 10 is arranged to compress the cylinder installation piece 14, and the compression cylinder 11 is placed on the compression cylinder installation piece 14. The long mouth includes a short piece 12 and a long piece 13 .

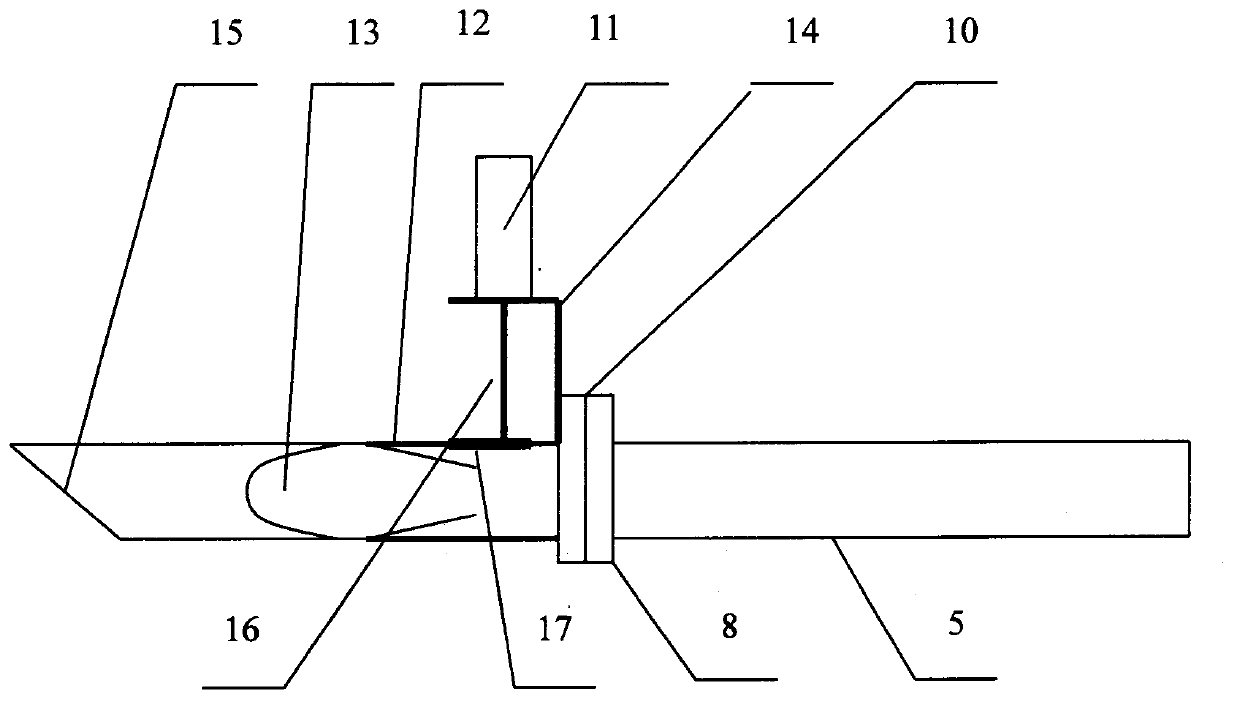

[0032] See image 3 . Compression cylinder mounting piece 14 becomes " 7 " word shape, and its vertical limit is connected on movable block 10 and fixes, and its horizontal limit arranges compression cylinder 11. Compression block 17 is connected under the compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com