Vibration feeding machine capable of being adjusted online in two levels

A vibrating feeder and vibrating motor technology, which is applied to vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of inconvenient adjustment and affecting work efficiency, and achieve easy operation, safe and reliable work, and small maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

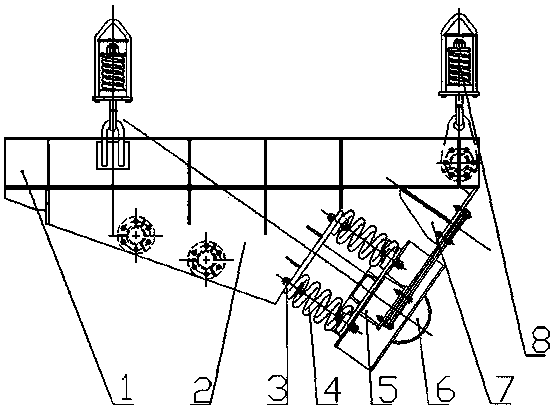

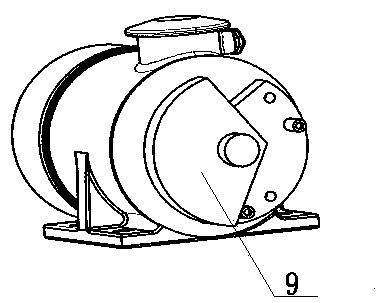

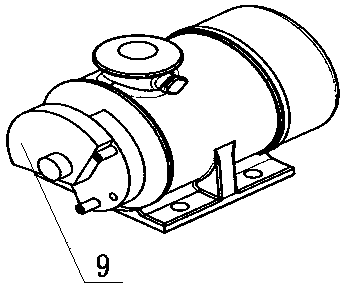

[0014] Such as figure 1 , figure 2 and image 3 As shown, a vibrating feeder capable of online two-speed adjustment includes a feeding trough 1, which is connected to the bin port through a shock absorber 8, and a vibrating motor 6 is connected to a motor base 5 through a bolt, and the motor base 5. The main vibrating spring 4 is connected to the connecting plate I3, the connecting plate I3 is fixedly connected to the thrust plate 2, the thrust plate 2 is fixedly connected to the feeding trough 1, and the vibration motor 6 is connected to the same eccentric wheel 9 on both sides.

[0015] Furthermore, the main vibrating spring 4 is a rubber composite compression spring, which is a linear spring and has the advantages of stable operation, stable amplitude, low noise, low energy consumption, large feeding capacity and long service life.

[0016] Further, the motor base 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com