Pile driving mechanism and pile driver

A technology for pile drivers and hangers, which is applied in sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of low equivalent force, high bearing reliability, gearbox lubricating oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

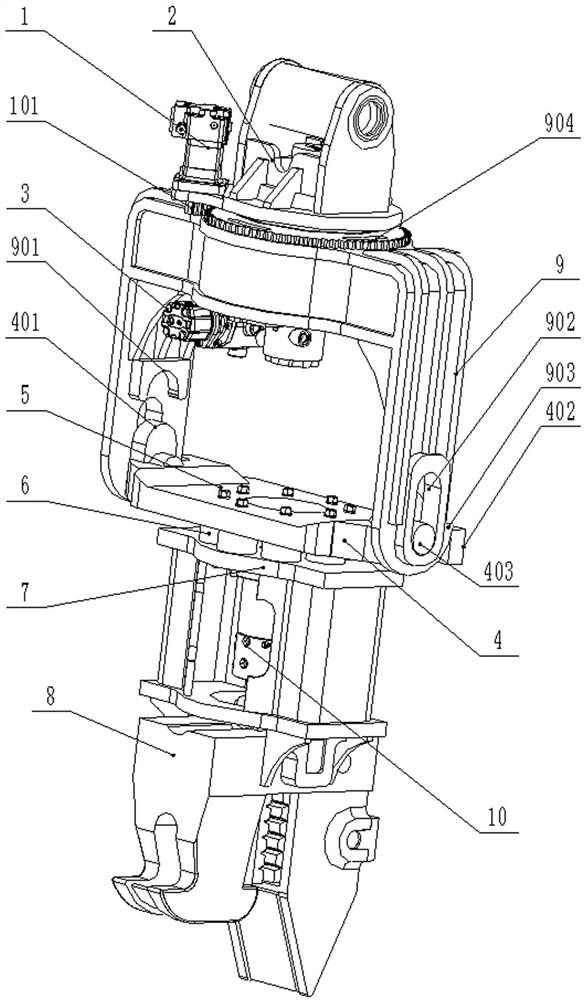

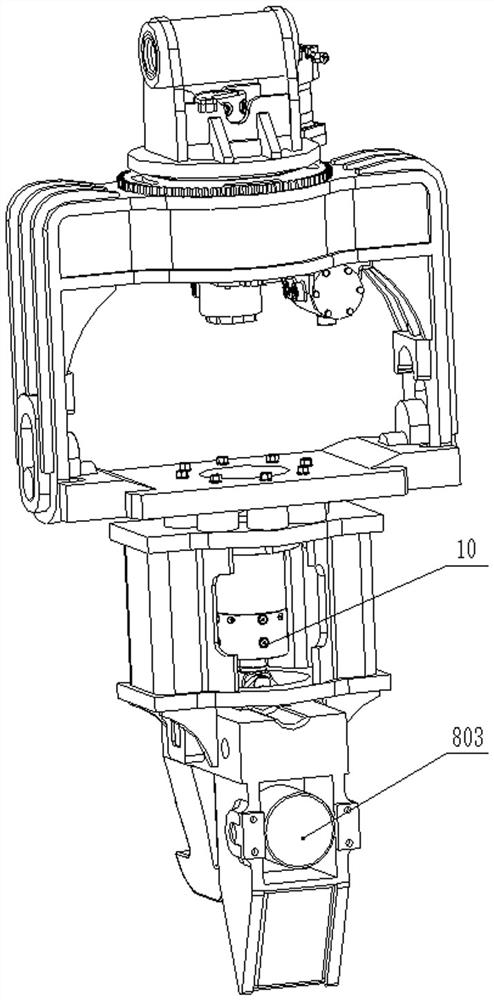

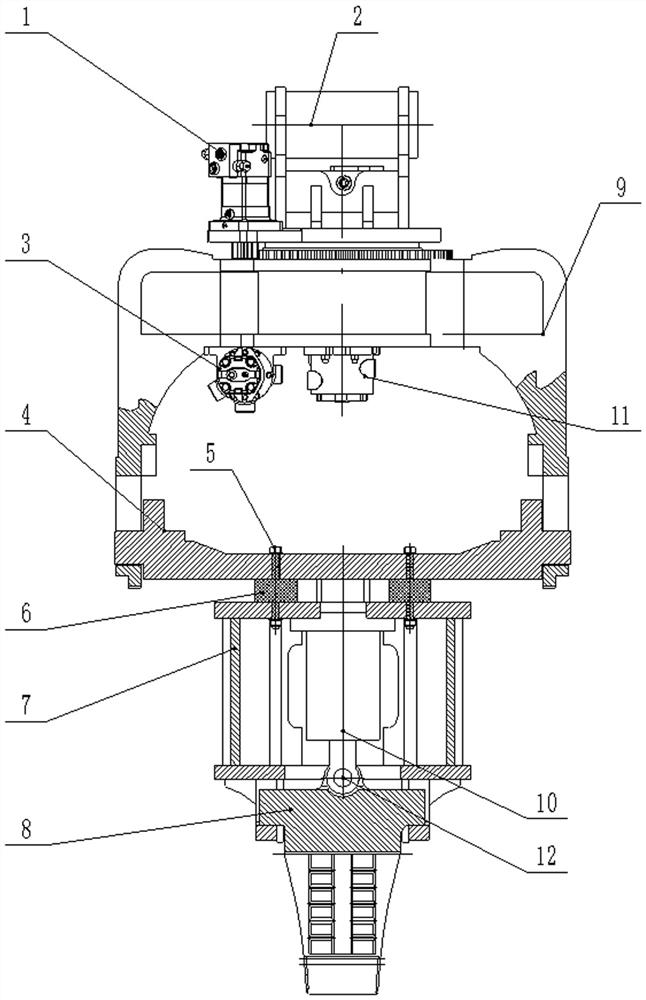

[0028] Embodiment one: if figure 1 and figure 2 As shown, the piling mechanism includes a hanger 9, a hydraulic cylinder 10, a fixed box 7 and a clamping hammer 8, and the bottom of the hanger 9 is equipped with a fixed box 7 that can move up and down, and one end of the hydraulic cylinder 10 is connected with the fixed box 7. The other end of the cylinder 10 is connected with the clamping tup 8, the two sides of the clamping tup 8 are respectively provided with a limiter 802, and the bottom of the fixed box 7 is provided with a chute 702 cooperating with the limiter 802 and with the clamping The limit plate 701 matched with both sides of the hammerhead 8 is a rib plate.

[0029] Such as Figure 5 and Figure 6 As shown, the clamping tup 8 includes a fixedly connected tup body 805 and a clamping plate 806, a clamping hydraulic cylinder 803 is provided between the tup body 805 and the clamping plate 806, and a limiting block 1 802 is arranged on On both sides of the hammer...

Embodiment 2

[0032] Embodiment 2: a rotatable support frame 2 is provided above the hanger 9, a drive motor 1 is installed on the support frame 2, a gear 101 is provided on the output shaft of the drive motor 1, and a fixedly connected rotary shaft is provided on the hanger 9. The ring gear 904 , the gear 101 meshes with the rotary ring gear 904 . The hydraulic oil drives the gear 101 of the output shaft of the drive motor 1 to rotate, thereby rotating through the slewing ring gear 904 on the meshing hanger 9, and then driving the relative rotation of the hanger 9 and the support frame 2, thereby passing through the fixed plate 4 and the shock absorber. 6 drives the fixed box 7 and the clamping hammer head 8 to rotate, and realizes the adjustment of the rotation angle of the clamping hammer head 8, so as to facilitate the angle adjustment of the clamping hammer head 8 and the pile 19 in the process of picking up piles, hanging piles and piles, and is convenient for operation construction. ...

Embodiment 3

[0037] Embodiment three: as Figure 7 As shown, the pile driver includes a pile driver body 12, a boom 14, a middle arm 16 and a small arm 18. The pile driver body 12 is mounted on the frame and the boom 14 is hinged, and the two ends of the middle arm 16 are respectively hinged with the boom 14 and one end of the small arm 18. , the other end of the small arm 18 is provided with the piling mechanism described in Embodiment 2; the small arm 18 is connected to the support frame 2, and the first oil cylinder 13 is arranged between the upper frame of the piling machine body 12 and the large arm 14, and the large arm 14 and A second oil cylinder 15 is arranged between the middle arms 16 , and a third oil cylinder 17 is arranged between the middle arm 16 and the small arm 18 .

[0038] When the present invention is in use, it is used in conjunction with a crawler excavator. During work, the pile 19 is fixed between the pressing plates 804 on the clamping hammer head 8 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com