Method for controlling nitrogen release in deep denitrification filter bed

A denitrification filter and release control technology, applied in anaerobic digestion treatment, etc., can solve the problems of increasing energy consumption, increasing backwash water consumption, shortening filtration cycle, etc., to reduce energy consumption, improve operating efficiency, and prolong filtration cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

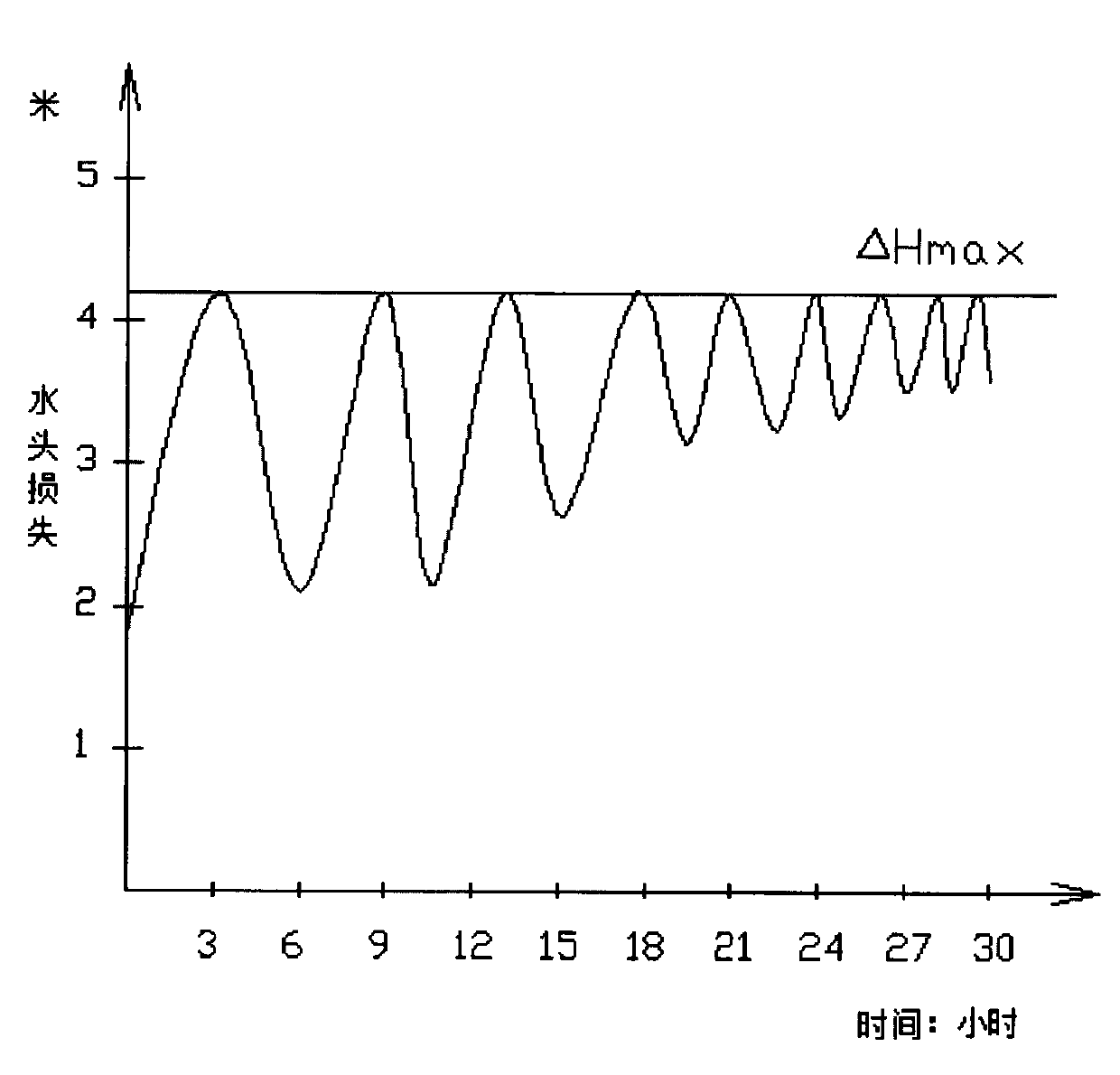

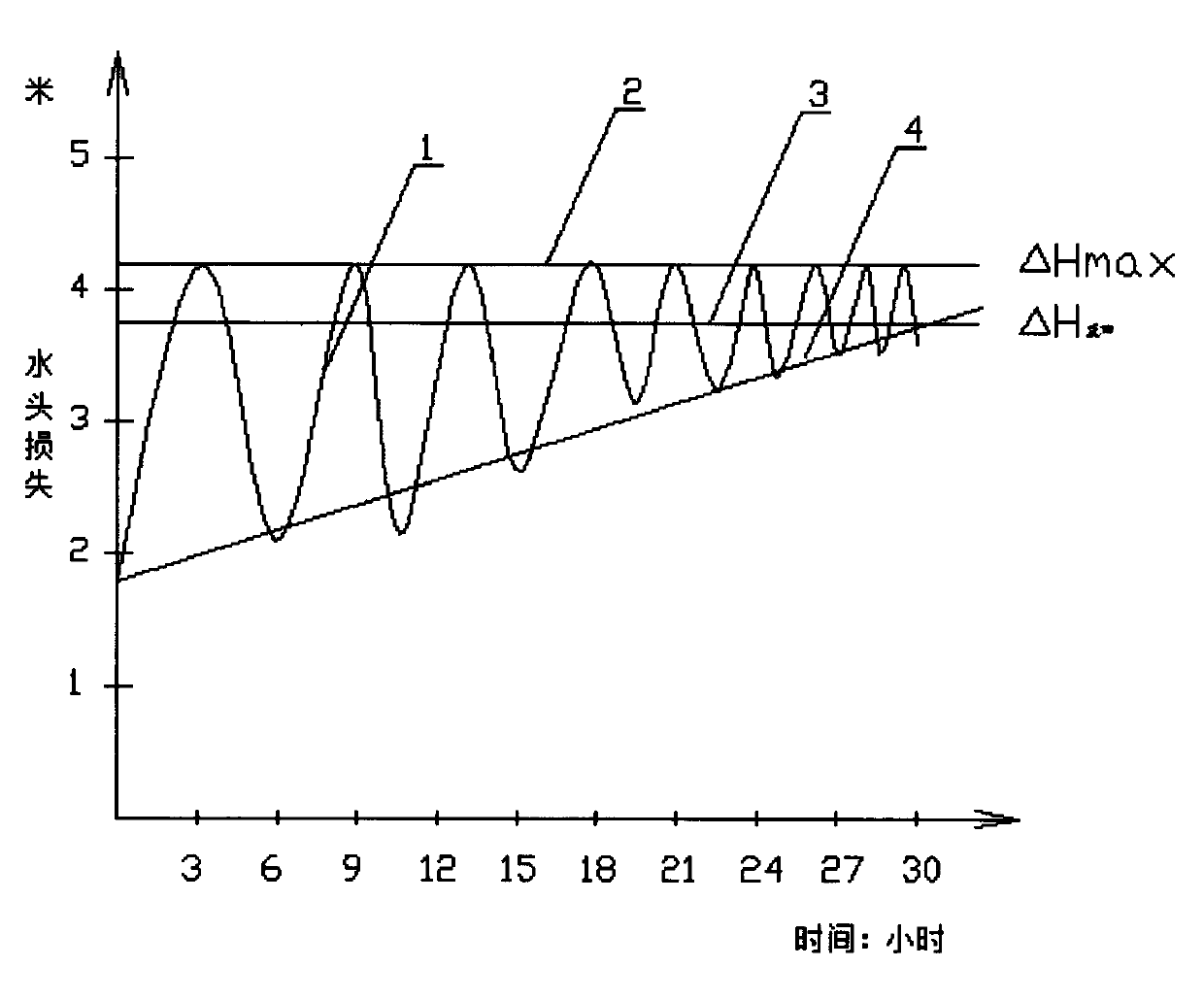

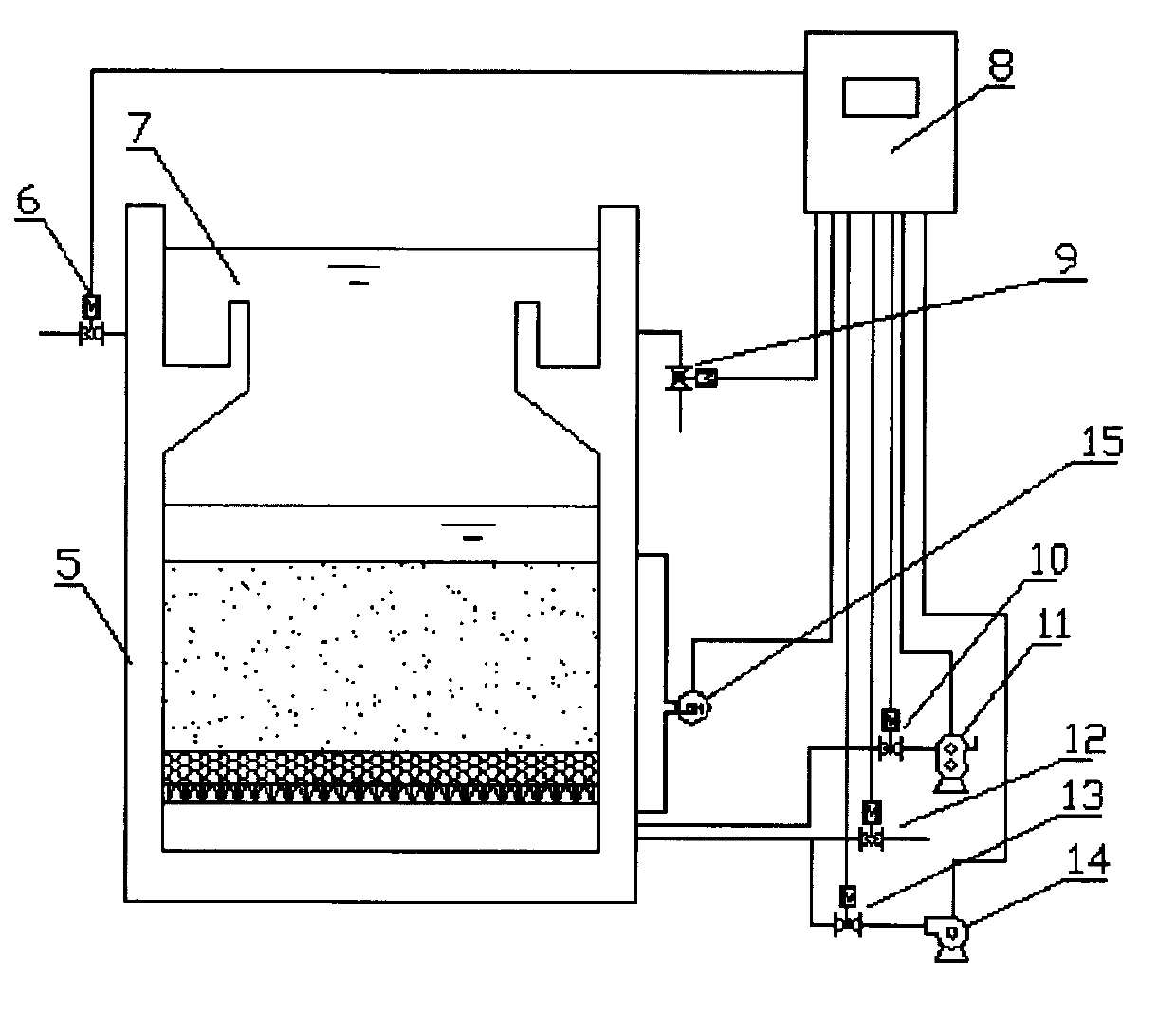

[0021] The key control factors of the total head loss control nitrogen release process are: (a) the head loss on-line detection instrument (15) participates in the nitrogen release control; (b) the head loss on-line detection instrument 15 does not participate in the gas-water recoil control, by calculating SS and The accumulation of biological sludge is compared with the maximum accumulation load to control the air-water recoil.

[0022] Nitrogen release process:

[0023] The measured value of head loss online detection instrument 15 is greater than or equal to the set value, and the nitrogen release program is started

[0024] Close the water inlet valve 6 and the water outlet valve 12

[0025] Open the recoil water inlet valve 13 and start the recoil water pump 14

[0026] ·Water recoil for 30-90 seconds

[0027] Close the recoil water pump 14 and the recoil water inlet valve 13

[0028] Open the outlet valve 12

[0029] Open the water inlet valve 6

[0030] Air water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com