Ceramic fiber paper

A technology of ceramic fiber paper and ceramic fiber, applied in fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, paper, etc., can solve the problems of poor durability, achieve good effect, good flame retardancy, and use long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

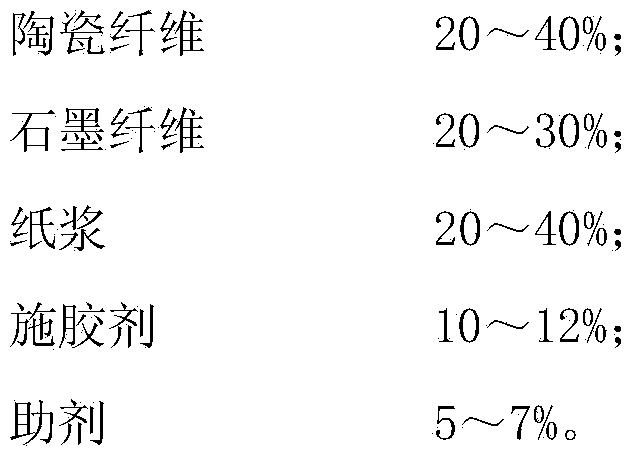

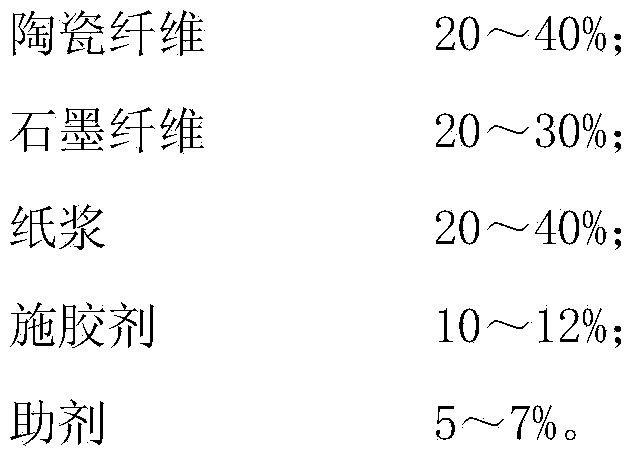

Method used

Image

Examples

Embodiment 1

[0014] Components and their weight ratio: 30% asbestos-free mineral fiber, 25% graphite fiber, 28% wood pulp, 12% rosin gum, 2.5% aluminum hydroxide powder, 1.25% sodium hydroxide powder, and 1.25% calcium sulfate powder.

[0015] Preparation method: grind the ceramic fiber and graphite fiber and put them into the stirring tank with the pulp, then add 2 times the volume of water; dissolve the additive in 1mol / L dilute hydrochloric acid solution and add it to the stirring tank; finally add sizing to the stirring tank agent, stirred for 1h; finally copied, dried, and molded.

Embodiment 2

[0017] Components and their weight ratio: 23% asbestos-free mineral fiber, 20% graphite fiber, 40% wood pulp, 10% paraffin glue, 3% aluminum hydroxide powder, 2% sodium hydroxide powder, and 2% calcium sulfate powder.

[0018] Preparation method: grind the ceramic fiber and graphite fiber and put them into the stirring tank with the pulp, then add 3 times the volume of water; dissolve the additive in 1mol / L dilute hydrochloric acid solution and add it to the stirring tank; finally add sizing to the stirring tank agent, stirred for 2 hours; finally copied, dried, and molded.

Embodiment 3

[0020] Components and their weight ratio: 37% asbestos-free mineral fiber, 28% graphite fiber, 20% pulp, 10% synthetic sizing agent, 2.5% aluminum hydroxide powder, 1.25% sodium hydroxide powder, and 1.25% calcium sulfate powder.

[0021] Preparation method: grind the ceramic fiber and graphite fiber and put them into the stirring tank with the pulp, then add 2 times the volume of water; dissolve the additive in 1mol / L dilute hydrochloric acid solution and add it to the stirring tank; finally add sizing to the stirring tank agent, stirred for 1.5h; finally copied, dried, and molded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com