A pulp molding double-sided rotary hub forming machine

A pulp molding and forming machine technology, applied in the direction of textiles and papermaking, can solve the problems of increased control system cost, difficult installation, high cost, etc., to reduce volume and mechanical strength, facilitate production and maintenance, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

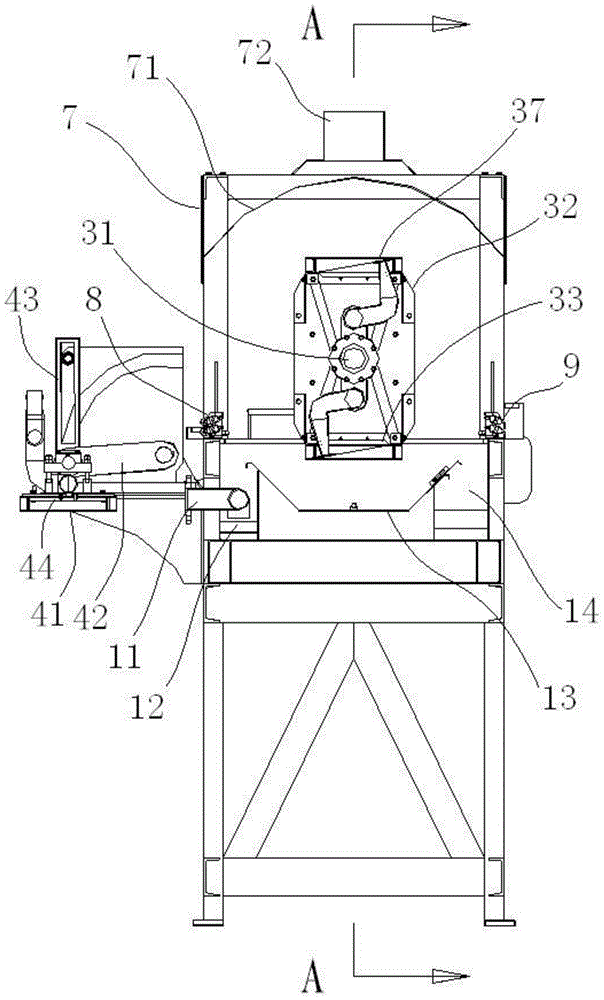

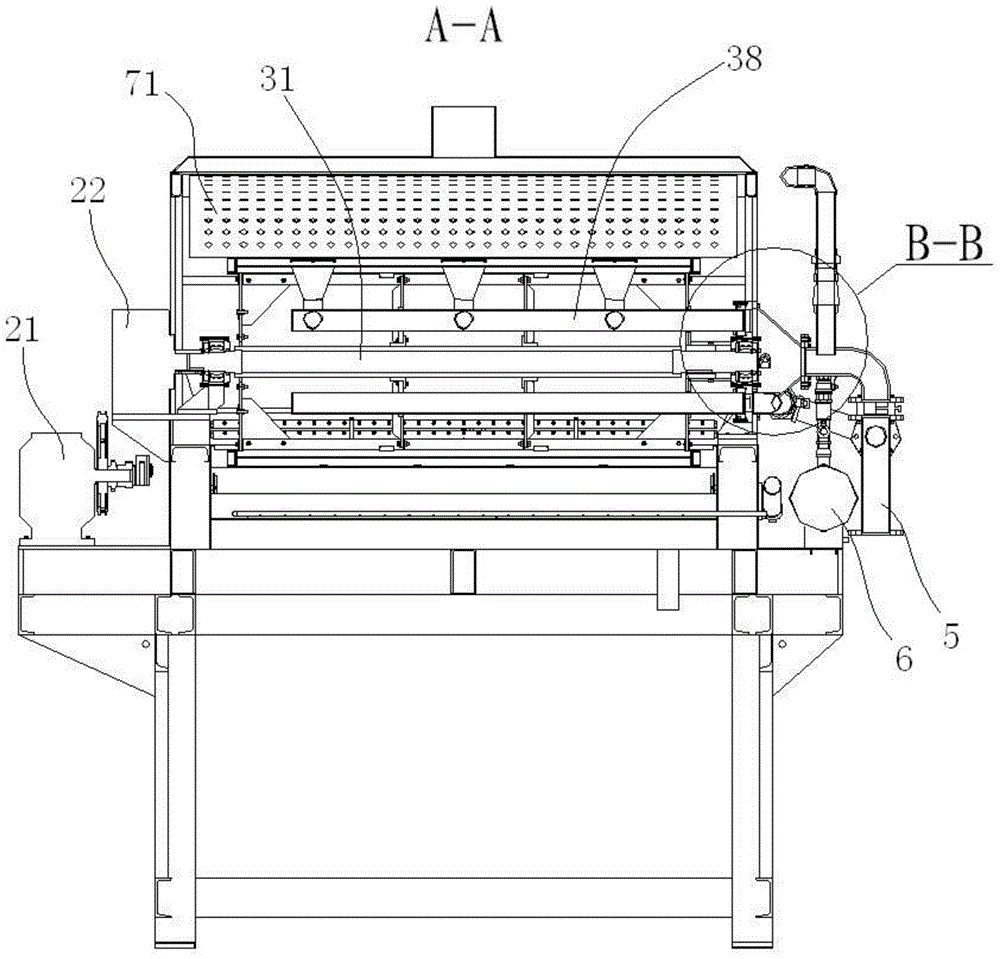

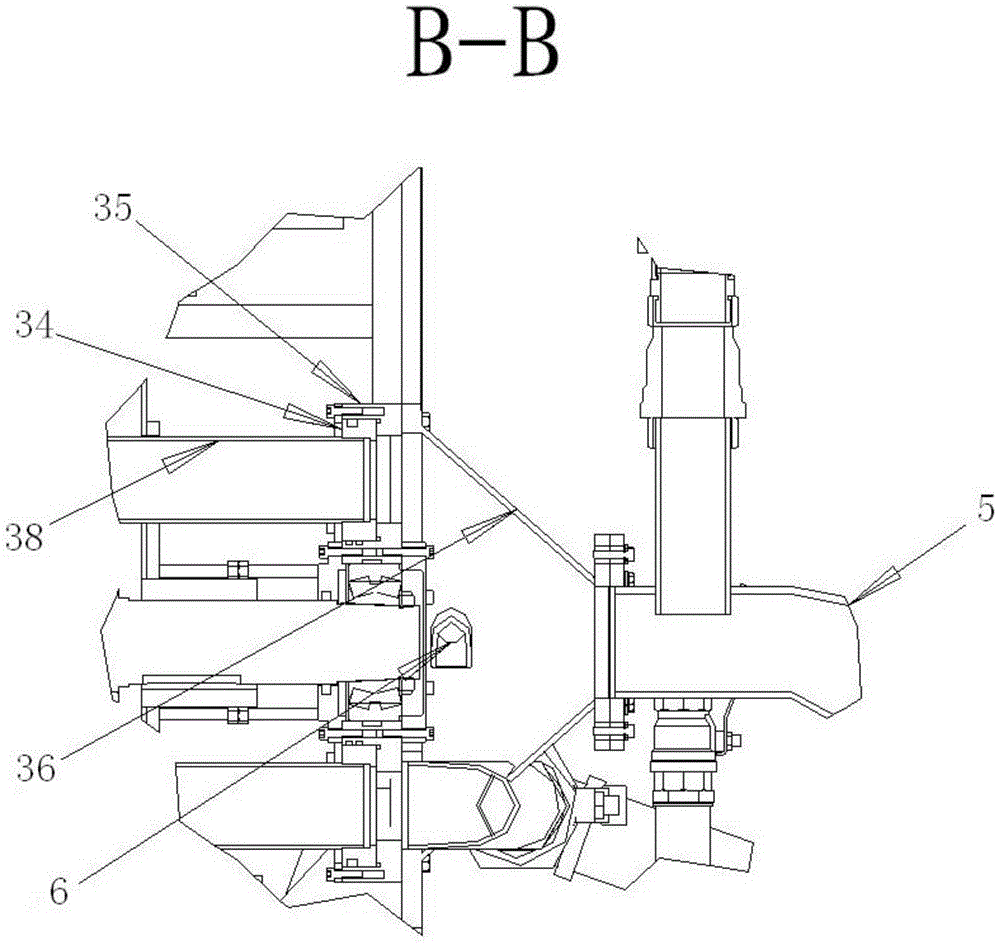

[0032] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] see in conjunction Figure 1 to Figure 6 As shown, a double-sided rotary hub forming machine for pulp molding includes a rotary hub intermittent drive mechanism 2 installed on a pulp box 1, a rotary hub forming mechanism 3, and a product removal mechanism 4. The rotary hub intermittent drive mechanism 2 is respectively connected with The hub forming mechanism 3 and the product removal mechanism 4 are connected. The pulp box 1 is composed of a pulp inlet pipe 11, a pulp inlet tank 12, a pulp storage tank 13, an overflow tank 14, and a return pipe connected in sequence. The hub intermittent drive mechanism 2 is a cam split drive mechanism, including a drive motor-reducer 21 and a cam divider 22, the drive motor-reducer 21 is installed on the base of the pulp box 1, and the cam divider 22 Installed at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com