Electric copied steel rail grinding machine

A grinding machine and profiling technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of inability to realize fast on-track operation, overall heavy weight, and low operating efficiency, and achieve compact structure, fast on-track operation, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

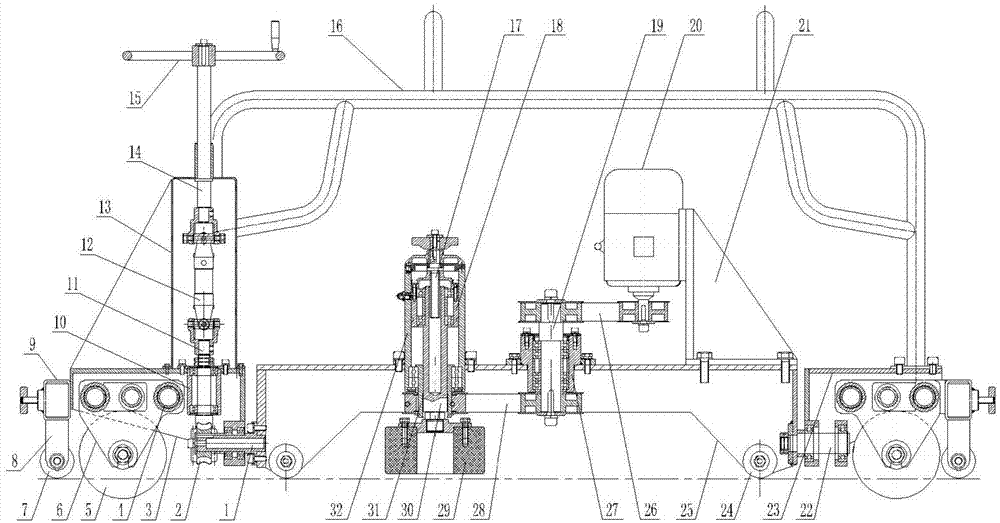

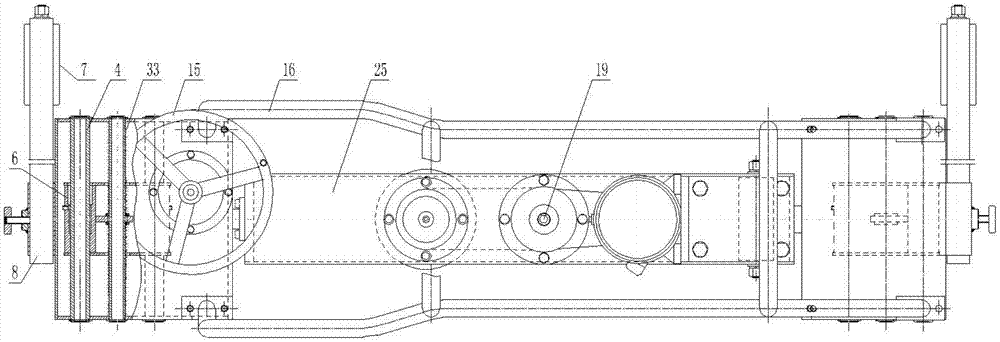

[0017] As shown in the figure, the electric profiling rail grinding machine includes two traveling wheel supports arranged front and back, which are respectively the first traveling wheel support 3 and the second traveling wheel support 23 . Three guide shafts 4 are respectively arranged side by side in the two traveling wheel supports, and the two ends of the guide shafts 4 pass through both sides of the traveling wheel supports respectively and are positioned by snap springs. Three guide shafts 4 in each travel wheel support are provided with a travel wheel frame 6, and a guide shaft 4 in the middle of the three guide shafts 4 is respectively provided with a pressure spring 33 on both sides of the travel wheel frame 6, The traveling wheel frame 6 is sheathed on the guide shaft 4 and is clamped in the middle by the pressure springs 33 on both sides. Rotatable road wheels 5 are installed on the bottom of the road wheel frame 6 by axles and bearings respectively.

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com