Cracking-preventing bridge structure

A bridge structure and anti-cracking technology, applied in bridges, bridge parts, bridge materials, etc., can solve problems affecting the safety of bridges, achieve the effects of preventing cracking and reducing the temperature difference between inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

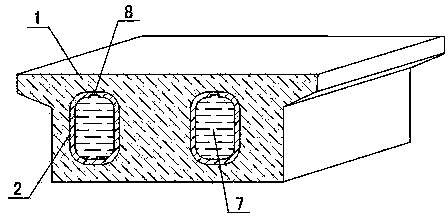

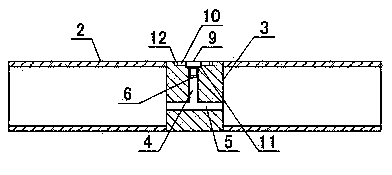

[0026] Such as figure 1 and figure 2 As shown, an anti-cracking bridge structure includes a concrete bridge body 1 and a steel cylinder 2 arranged in the concrete bridge body 1; the steel cylinder 2 is a rectangular hollow steel cylinder, the two ends of the steel cylinder 2 are closed, and the middle part of the steel cylinder 2 is A solid body 3, the top of the solid body 3 is provided with a water inlet hole 4 extending vertically downward, and the side of the solid body 3 is provided with a water outlet hole 5 extending horizontally and communicating with the water inlet hole 4 and the hollow part of the steel cylinder 2; The upper end of the water inlet hole 4 is provided with a threaded plug 6; the hollow part of the steel cylinder 2 is filled with water 7.

[0027] The installation process of the present invention is as follows:

[0028] Water 7 is injected into the steel cylinder 2 through the water inlet hole 4 , and then the water inlet hole 4 is blocked by a scre...

Embodiment 2

[0030] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the inner upper surface of the steel cylinder 2 is provided with an accommodation groove 8 , and the height of the water surface is lower than the accommodation groove 8 .

Embodiment 3

[0032] Such as figure 2 As shown, on the basis of any one of the above-mentioned embodiments, this embodiment also includes a protective cover 9, the protective cover 9 is disc-shaped, and a plurality of connecting blocks 10 are arranged on the outer circular surface of the protective cover 9; the solid The top of the body 3 is provided with a circular groove 11, and the water inlet 4 extends vertically downward from the bottom of the circular groove 11; the circular groove 11 is compatible with the protective cover 9, and the surroundings of the circular groove 11 are provided with accommodating connection The accommodating opening 12 of the block 10 is welded to the connecting block 10 and the accommodating opening 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com