gas scrubber

A technology of gas scrubber and washing room, which is applied in fuel air filter, machine/engine, combustion air/combustion-air treatment, etc., which can solve the problem of increased gas flow resistance, poor filtering effect, uneconomical use, etc. problem, to achieve the effect of guaranteed throughput, low cost of use and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

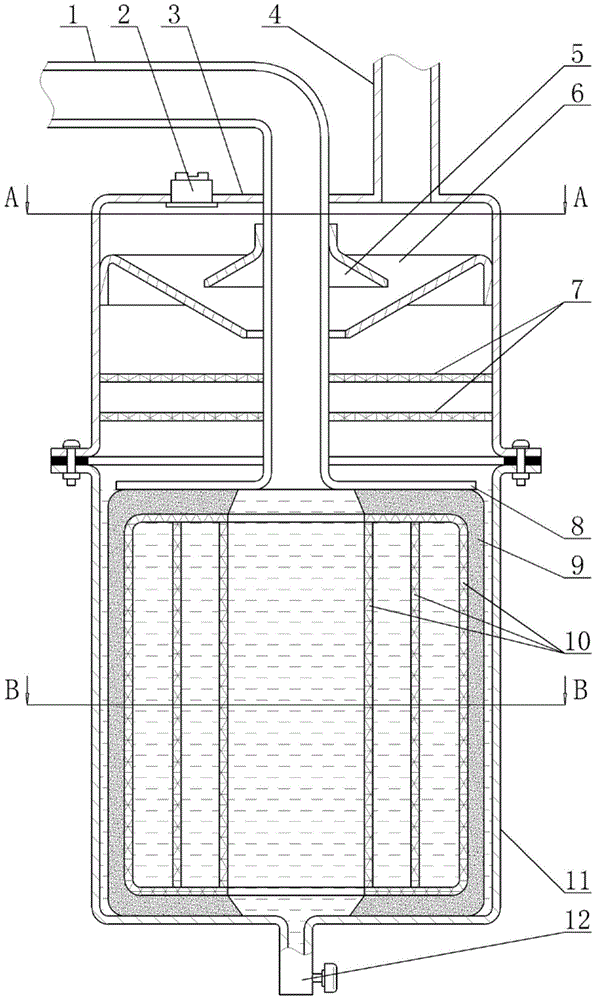

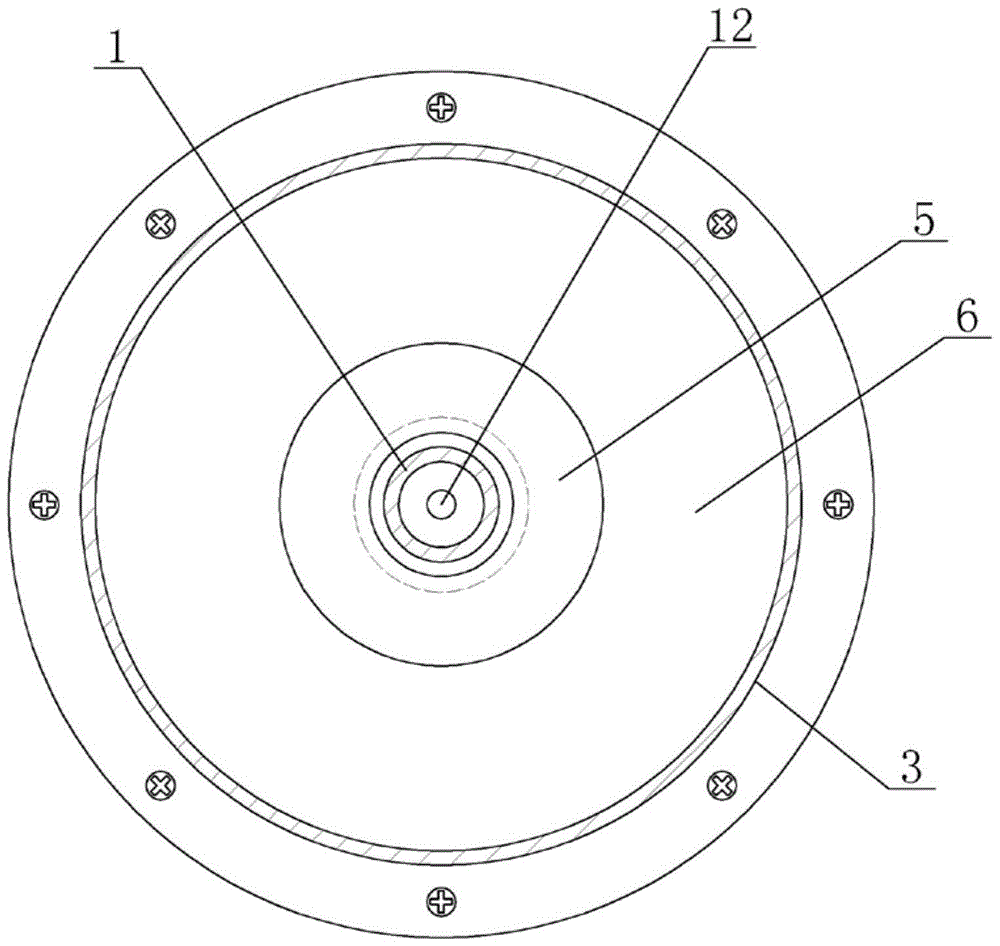

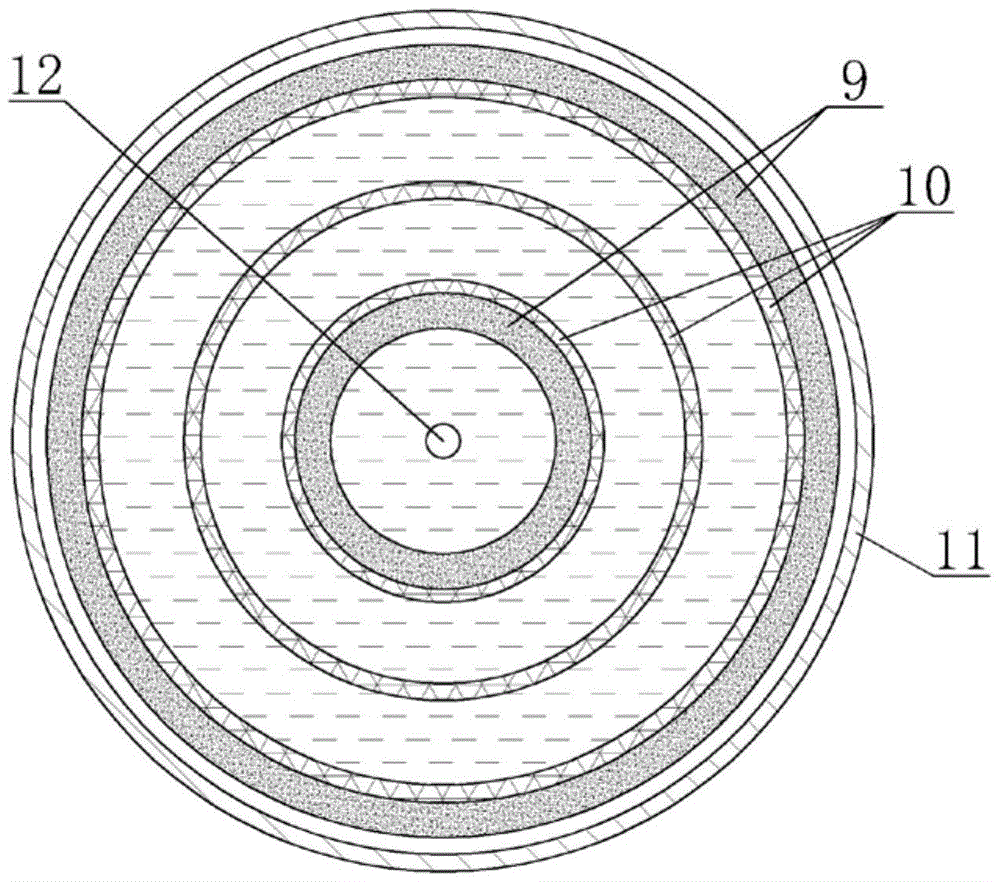

[0015] The gas scrubber has a metal tank. The top of the tank is provided with a water filling valve 2 for adding water or antifreeze to the tank. The bottom of the tank is provided with a drain valve 12 for discharging dirty liquid. The tank is equipped with Air intake pipe 1 and anti-overflow funnel 6, the wide mouth edge of anti-overflow funnel is fixedly connected with the inner wall of the tank, the narrow mouth of anti-overflow funnel is set on the air intake pipe, and an airflow channel is arranged between the edge of the narrow mouth and the air intake pipe, The space inside the tank above the spill-proof funnel is a gas collection room, which is used as a buffer room for the purified gas, and the space inside the tank below the spill-proof funnel is a washing room, which is used to filter impurities. There is water or antifreeze, water is used as the gas cleaning medium in summer, and antifreeze is used as the gas cleaning medium in winter. The trachea is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com