High-temperature and abrasion resistant ball valve of linkage two-position ball

A high-temperature and wear-resistant technology, applied in the field of linked two-position ball high-temperature and wear-resistant ball valves, can solve problems such as leakage and easy wear, and achieve the effects of long service life, good safety performance, and not easy to leak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

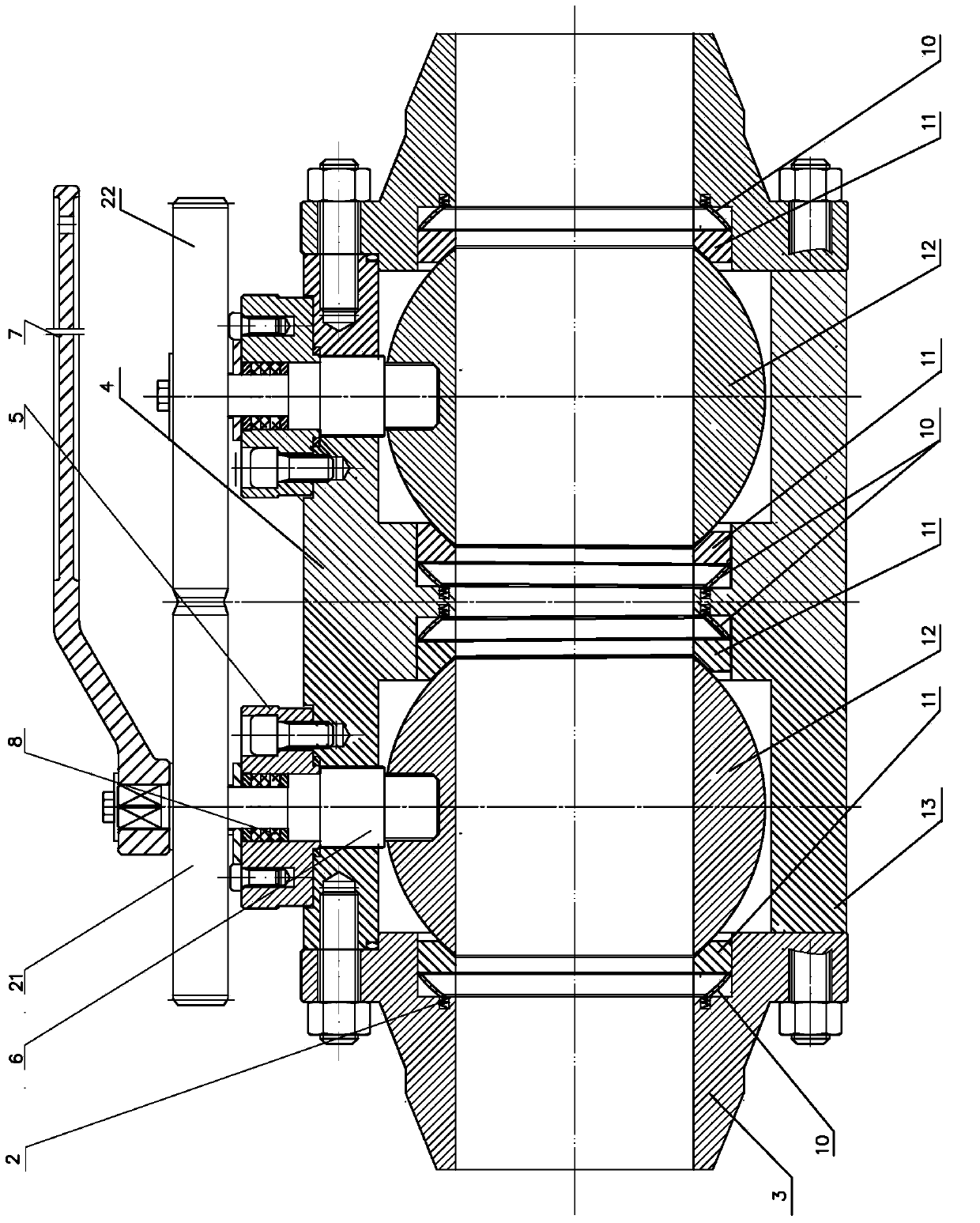

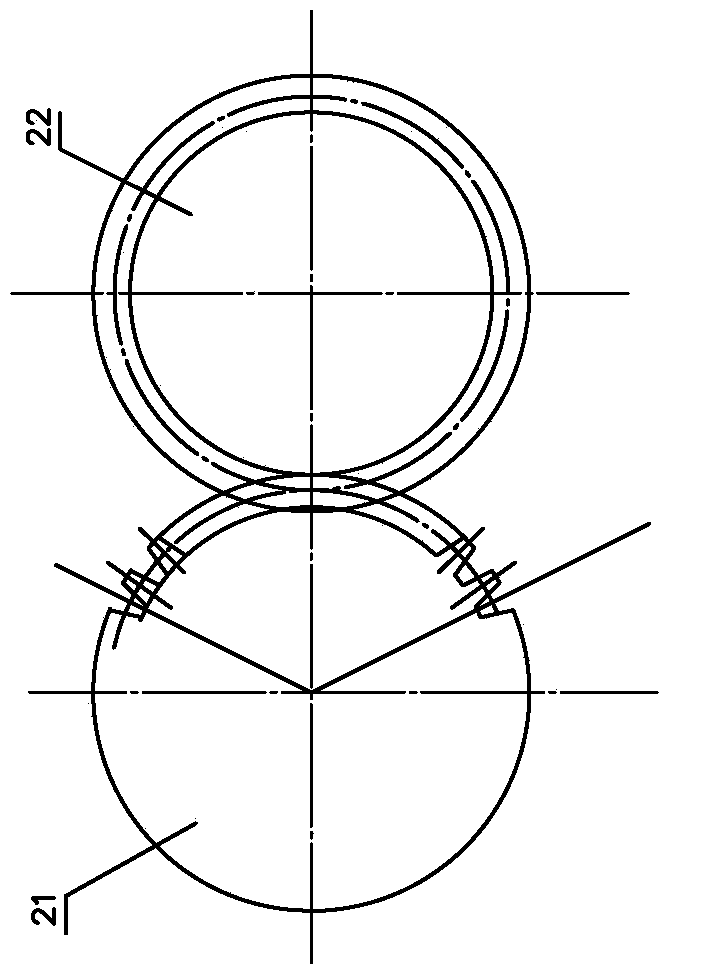

[0018] Embodiment: The present invention is a linkage two-position ball high-temperature and wear-resistant ball valve, as attached figure 1 As shown, it includes a valve body, a valve seat 11, a butterfly spring 10, a ball 12, a valve stem 6, and a valve cover 4, and the valve body includes a left valve body 3, a middle valve body 13, and a right valve body 9. The middle valve body 13 is provided with two cavities, and the middle part of the two cavities is connected and a sphere 12 is provided respectively. Each sphere 12 is provided with a valve stem 6; the oil holes on the two spheres 12 are arranged in parallel, and the two valve stems 6 are driven through synchronous transmission. The mechanism constitutes a transmission connection; the end of one of the two valve rods 6 is provided with an operating mechanism for operating the rotation of the ball 12 . One or two valve seats 11 are respectively arranged in the two cavities of the middle valve body 13, and the two valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com