Special expansion joint for pulverized coal guide

An expansion joint and guiding technology, which is applied in expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as high cost, short service life of compensators, leakage, etc., and achieve simple structure, The effect of long service life, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

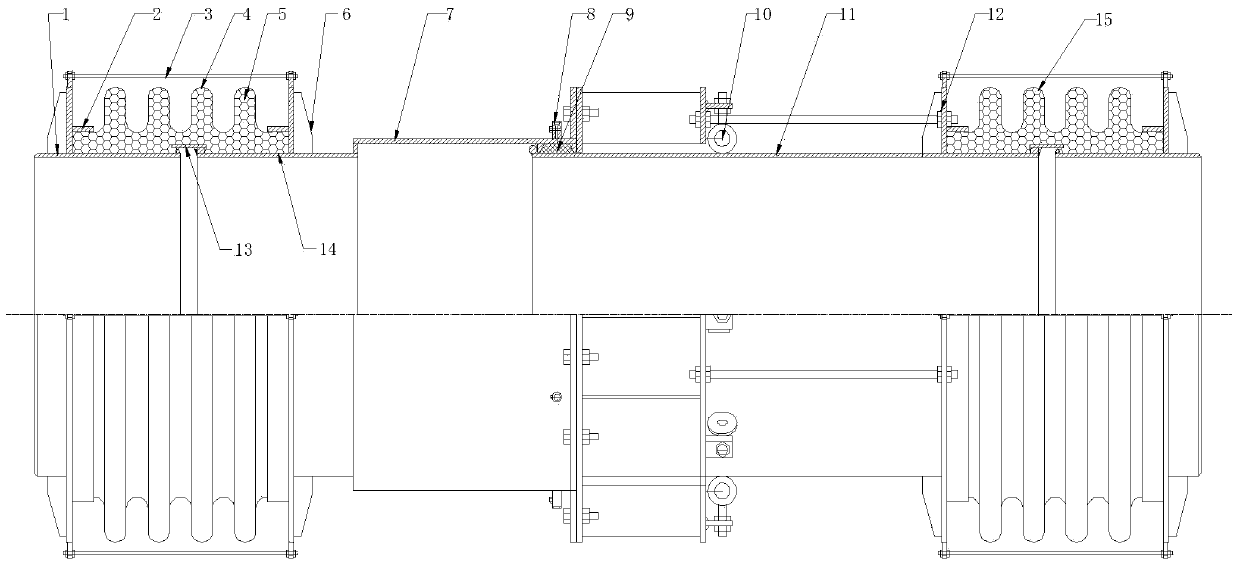

[0018] Such as figure 1 As shown, the special expansion joint for pulverized coal guidance includes bellows arranged at both ends and a telescopic intermediate connecting pipe connecting the bellows at both ends. The telescopic intermediate connecting pipe includes an intermediate connecting pipe 7 and a telescopic connecting pipe 11. One end extends into one end of the intermediate connecting pipe 7, the other end of the intermediate connecting pipe 7 is connected to the first bellows 4, the other end of the telescopic connecting pipe 11 is connected to the second bellows 15, and the telescopic connecting pipe 11 and the intermediate connecting pipe 7 are connected to each other. A sealing packing 9 is provided, and the intermediate connecting pipe 7 is connected with the second bellows 15 through an axial guide assembly.

[0019] The axial guide assembly includes a cylindrical connecting pipe and a pull rod assembly, one side of the cylindrical connecting pipe is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com