Acceptance inspection tool for mounting dimension of small-amount standalone product

An installation size, stand-alone technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of large cumulative error, low acceptance efficiency, non-rectangular arrangement of installation holes, etc., to improve quality and efficiency, and ensure quality. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

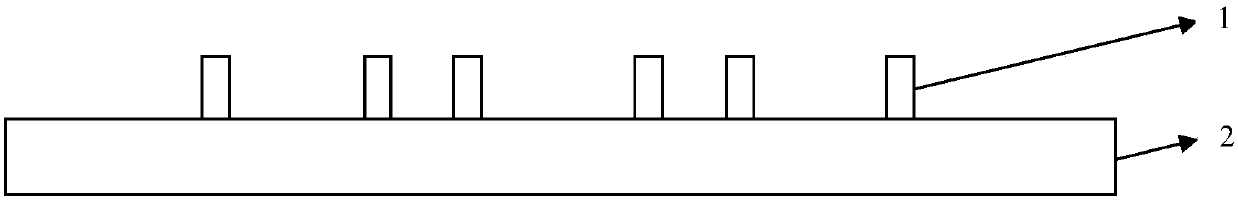

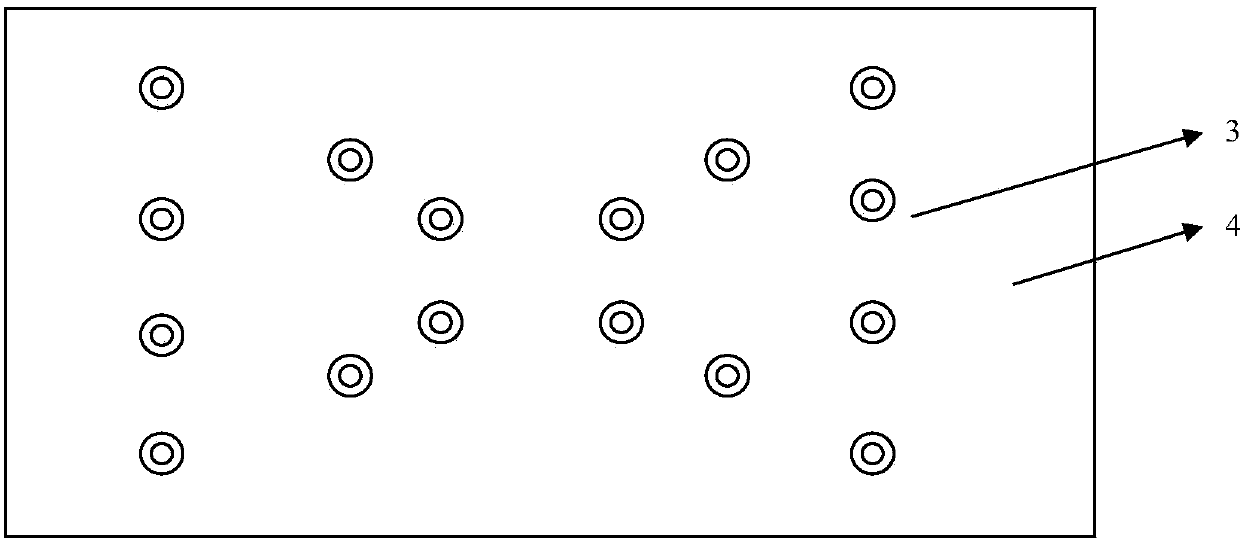

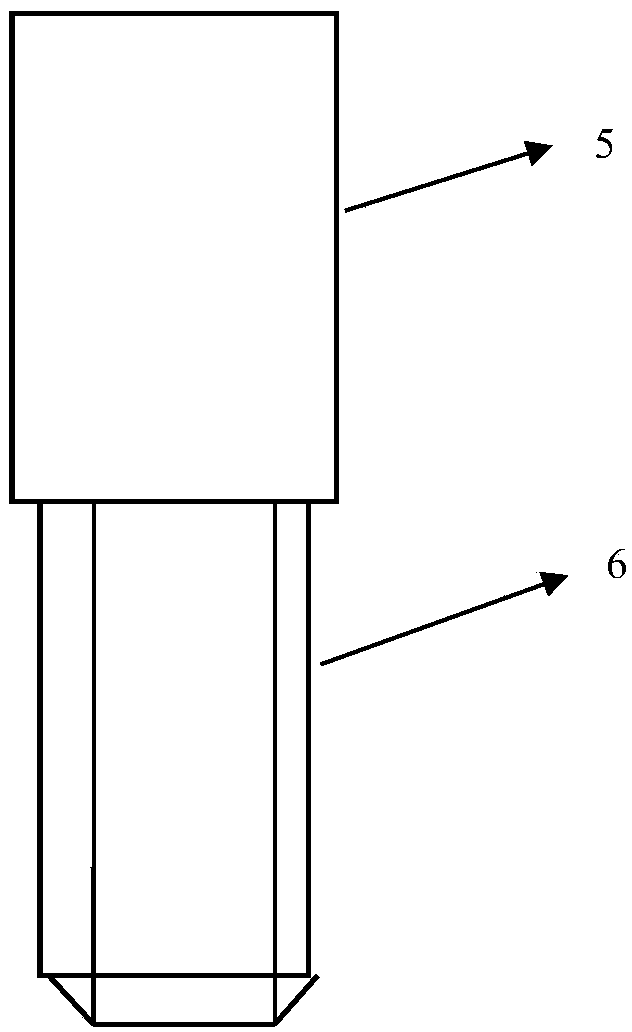

[0022] see Figure 1-3 , figure 1 It is a structural schematic diagram of the small-batch stand-alone product installation size acceptance tooling of the present invention; figure 2 It is a schematic front view of the bottom plate of the small-batch stand-alone product installation size acceptance tooling of the present invention; image 3 It is a schematic diagram of the measurement column in the small-batch stand-alone product installation dimension acceptance tooling of the present invention. Among them, the small-batch stand-alone product installation size accept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com