Analysis method for impurity content of exenatide

A technology of exenatide and analysis method, applied in the field of analysis of exenatide impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Embodiment 1: ([D-His 1 ]-Exenatide)

[0100] 1. Chromatographic conditions:

[0101] Instrument: High Performance Liquid Chromatography—UV Detector

[0102] Chromatographic column: strong cation exchange column [PolysulfoEthyl A TM (3μm, 4.6*100mm, 300A)]

[0103] Mobile phase: Potassium dihydrogen phosphate buffer (take 4.76g of potassium dihydrogen phosphate, add water 1000ml to dissolve. Phosphoric acid adjusts the pH value to 4.0)-acetonitrile (56.4:43.6)

[0104] Column temperature: 50°C. Wavelength: 214nm. Flow rate: 1.2ml / min. Injection: 40 μl.

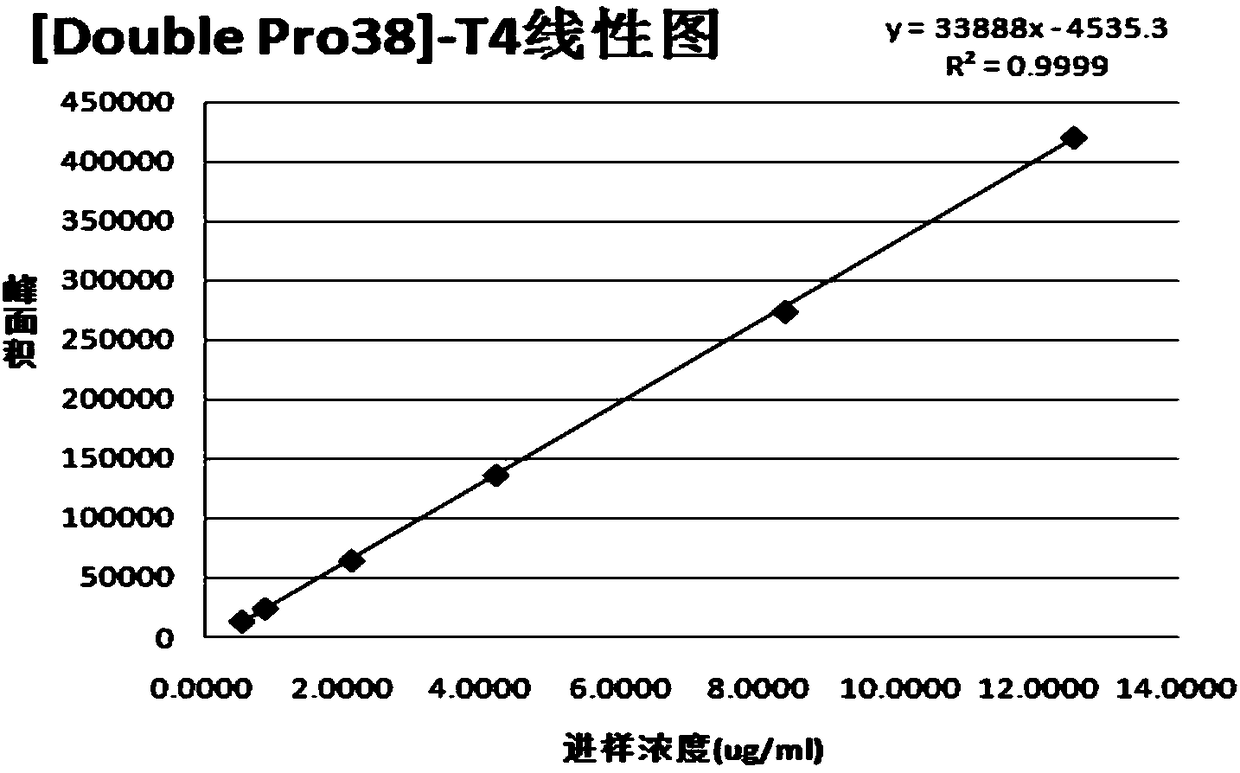

[0105] 2. Validation of analytical methods

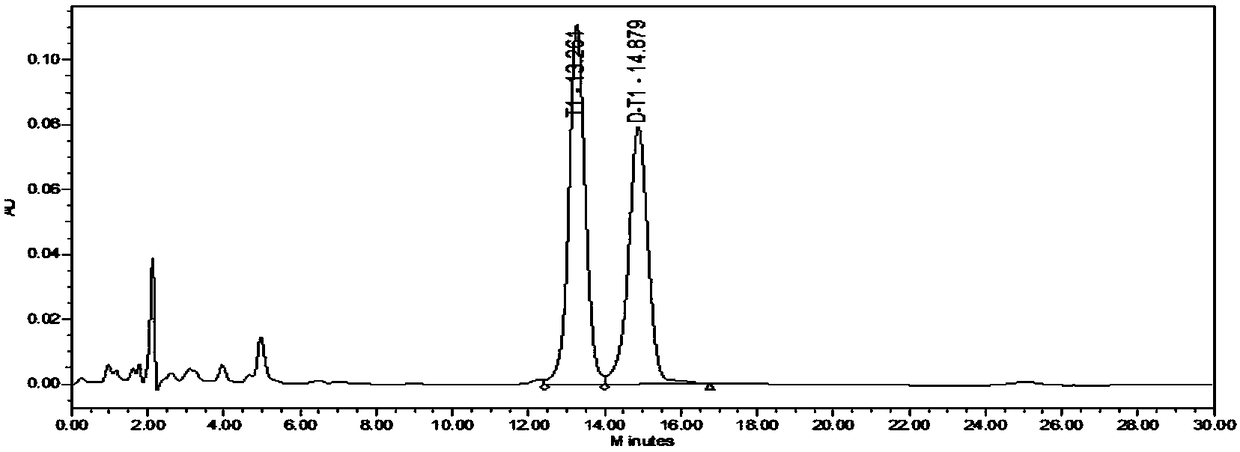

[0106] 1) Specificity

[0107] (1) Blank solvent: Take 15ml of 1% ammonium bicarbonate solution, put it in a 50ml measuring bottle, add 1.5ml of trypsin solution, mix well, heat in a 37°C water bath for 0.5h, let cool, add 5ml of dilute phosphoric acid solution, mix well, Add 15ml of 1% ammonium bicarbonate solution, mix well, add water to dilute to the mark, and ob...

Embodiment 2

[0140] 1. Chromatographic conditions:

[0141] Instrument: High Performance Liquid Chromatography—UV Detector

[0142] Chromatographic column: use octadecylsilane bonded silica gel as filler [X-TerraMSC18 (5.0μm, 4.6*150mm)]

[0143] Mobile phase: A: 0.1mol / L potassium chloride solution (take 7.4g of potassium chloride, add 1ml of triethylamine, add water to 1000ml, adjust pH to 2.7 with phosphoric acid)

[0144] B: Acetonitrile

[0145] gradient elution procedure

[0146]

[0147] Column temperature: 45°C. Wavelength: 214nm. Flow rate: 1.0ml / min. Injection: 80 μl.

[0148] 2. Validation of analytical methods:

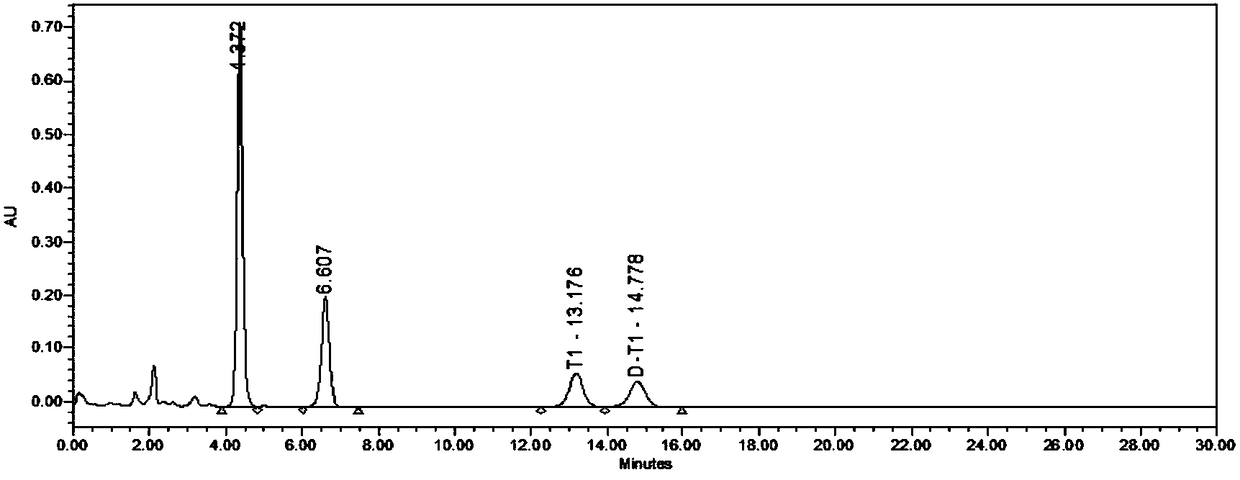

[0149] 1) Specific solution

[0150] (1) Blank solvent: Take 15ml of 1% ammonium bicarbonate solution, put it in a 25ml measuring bottle, add 1.5ml of trypsin solution, vortex and mix, put it in a 37°C water bath and heat for 0.5h, then add 2ml of glacial acetic acid to terminate the reaction, Add water to make up to the mark, shake well, and you get it.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com