Novel gas turbine low-pressure compressor rotor structure and assembling method

A technology for compressor rotors and gas turbines, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc. It can solve the problems of many parts, affecting the centering and balance of rotors, and uncontrollable quality, so as to reduce the number and reduce leakage. The effect of air loss and reliable force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

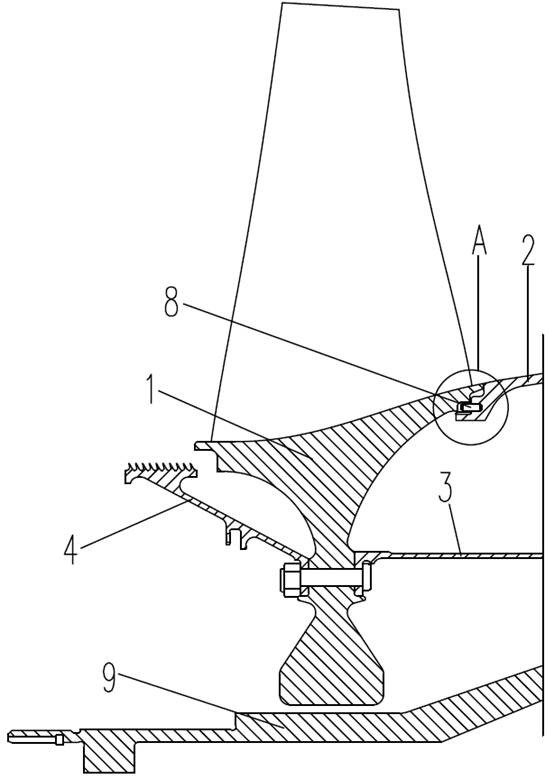

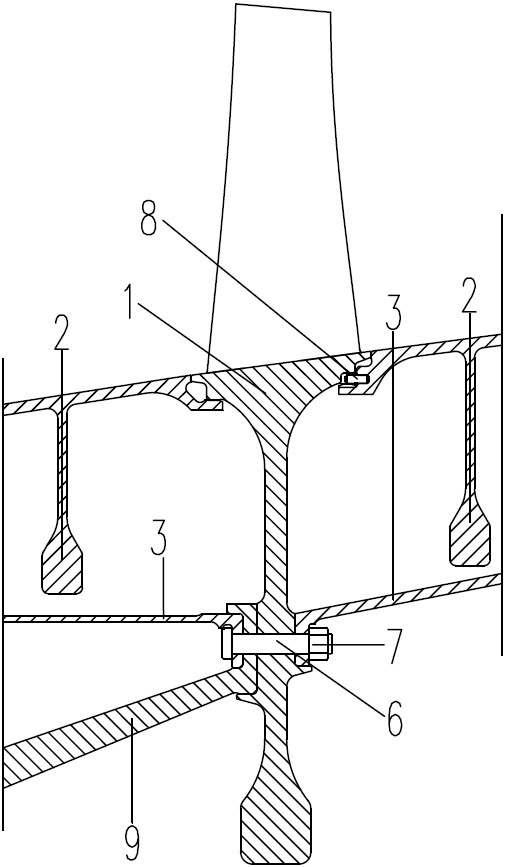

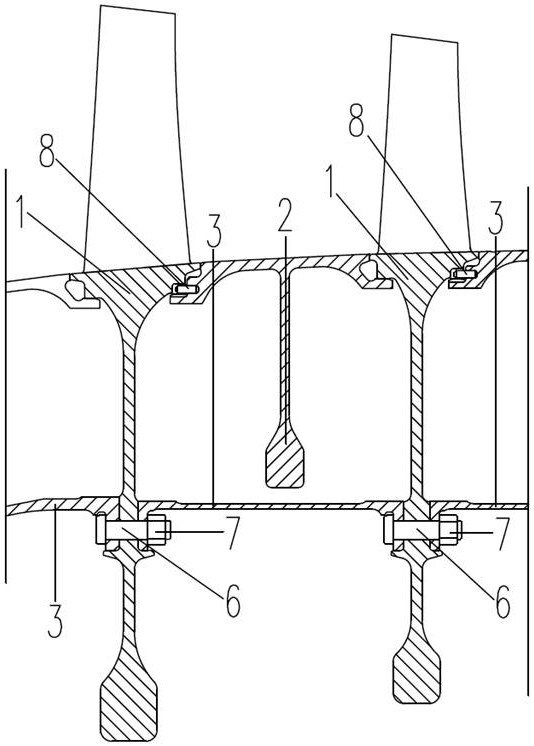

[0026] Such as Figure 1-5 As shown, the present embodiment provides a novel gas turbine low-pressure compressor rotor structure, including one to six working impellers 1 installed on the low-pressure compressor shaft and sequentially arranged from the front end to the rear end of the low-pressure compressor. The rotating shaft connects the working impellers 1 at all levels into one body and the associated structures into one.

[0027] Wherein, the outer sides of any adjacent two-stage working impellers 1 are connected by a passage ring assembly 2, and the inner sides of any adjacent two-stage working impellers 1 are connected by a spacer ring assembly 3, so that the two adjacent The first-stage working impellers 1 can be stably connected together, so that the first to sixth-stage working impellers 1 are combined into a stable whole; The end of the sixth-stage working impeller 1 close to the rear end of the low-pressure compressor is connected with the rear sealing grate toot...

Embodiment 2

[0037] This embodiment provides a method for assembling the rotor structure of a novel gas turbine low-pressure compressor as described in Embodiment 1, including the following specific steps:

[0038] Before assembly, put the low-pressure compressor shaft, first to sixth stage working impellers 1, all passage ring components 2, all spacer ring components 3, front sealing grate tooth disc 4, rear sealing grate tooth disc 5, all bolts 6. All lock nuts 7 and all pins 8 are aligned in place according to the installation position;

[0039] When assembled in place, rotate the working impeller 1, the passage ring assembly 2, the spacer ring assembly 3, the front sealing grate tooth plate 4, the rear sealing grate tooth plate 5, the front journal of the low-pressure compressor 9 and the rear journal of the low-pressure compressor The angular position of 10 to ensure the amount of runout.

[0040] When assembling, pre-tighten all the lock nuts 7 on the corresponding bolts 6 according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com