Rotary station wire inserting machine

A wire-embedding machine and station technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems such as the inability to improve the production efficiency of the wire-embedding machine, the higher requirements for manual skills, and the impact on the performance of the stator. Achieve a good scope of application, ensure normal operation, and prevent equipment damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

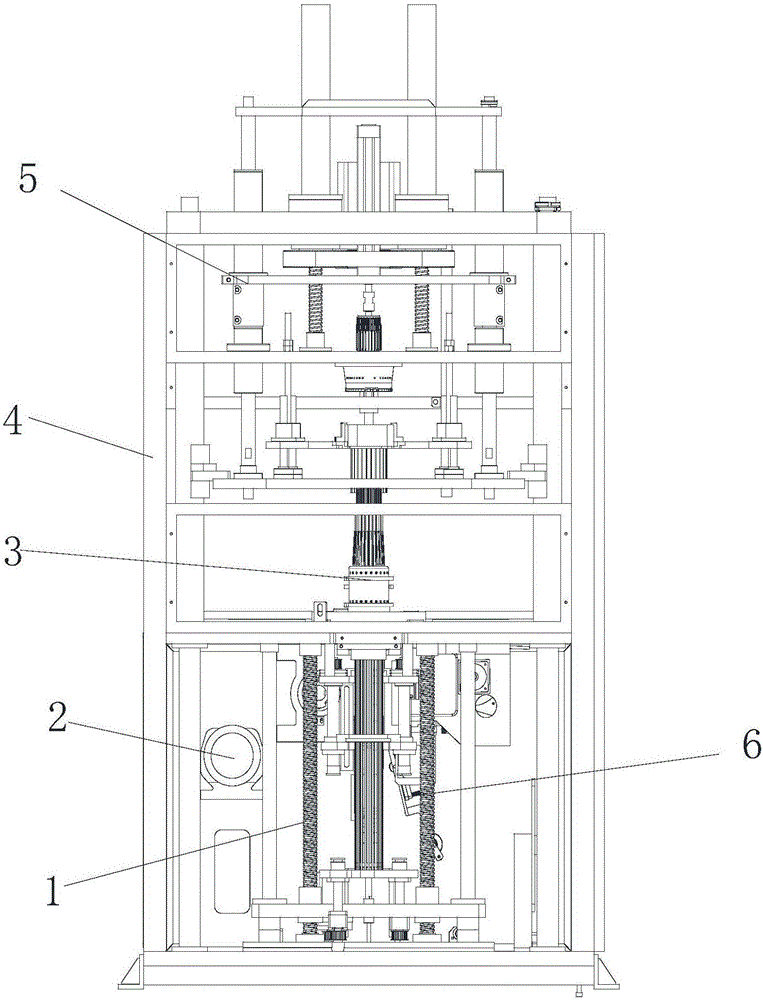

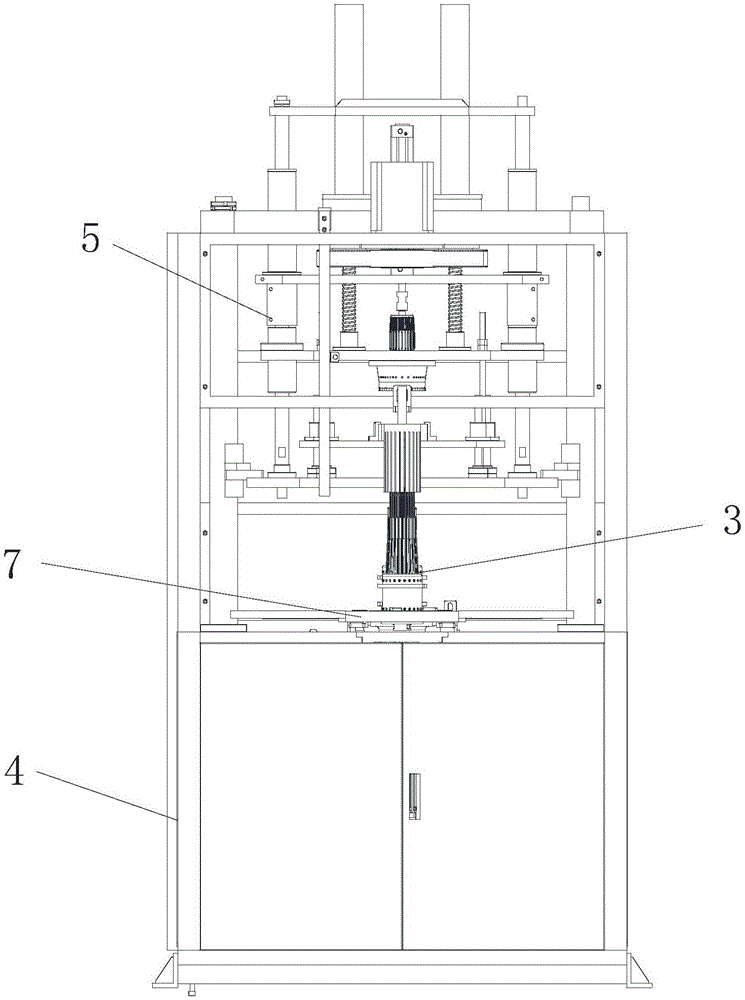

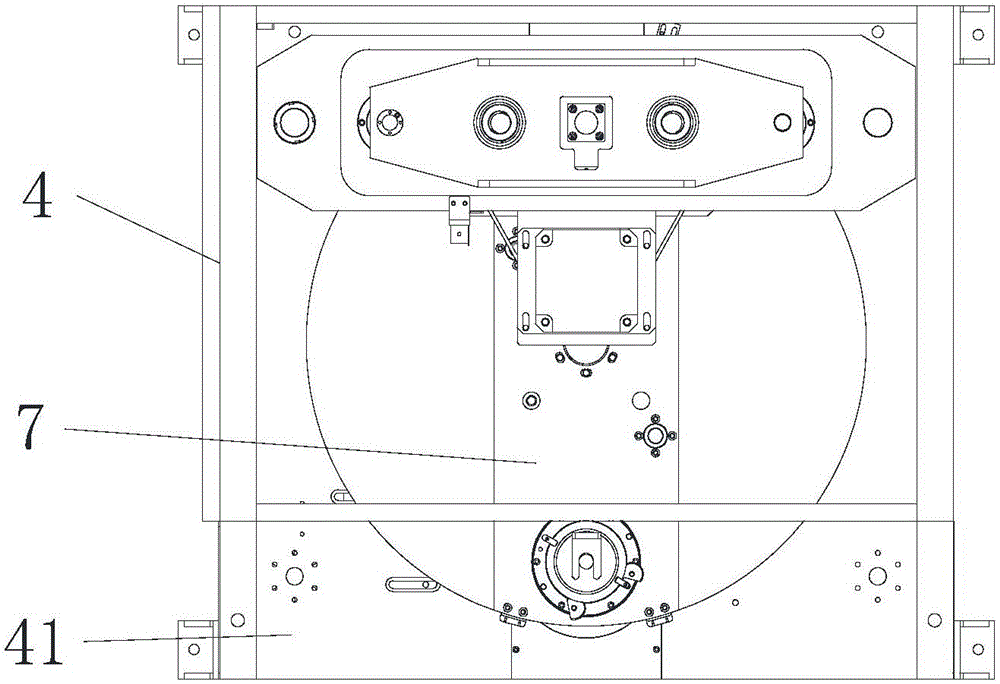

[0045] Such as Figure 1 to Figure 5 The shown rotary station wire inserting machine includes a frame 4, the lower part of the frame 4 is provided with a lower mounting plate 42, the middle part of the frame is provided with a middle mounting plate 41, and the rotating mechanism of the middle mounting plate 41, Described turning mechanism comprises the turntable rotating indexer 8 that is installed on the lower surface of middle mounting plate 41 driven by the motor, the output end of turntable rotating indexer 8 stretches out the upper surface of middle mounting plate, and the output end of turntable rotating indexer is connected with installation method. Lan, the rotating plate 7 is connected to the mounting flange; the rotating mechanism is used to drive the rotating plate to rotate, so as to realize the switching of the stations on the rotating plate 7. The middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com