heat-expandable formulations

A technology of thermal expansion and preparation, which is applied in the field of thermal expandable preparations, and can solve the problems of insufficient anti-sag and non-sag properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

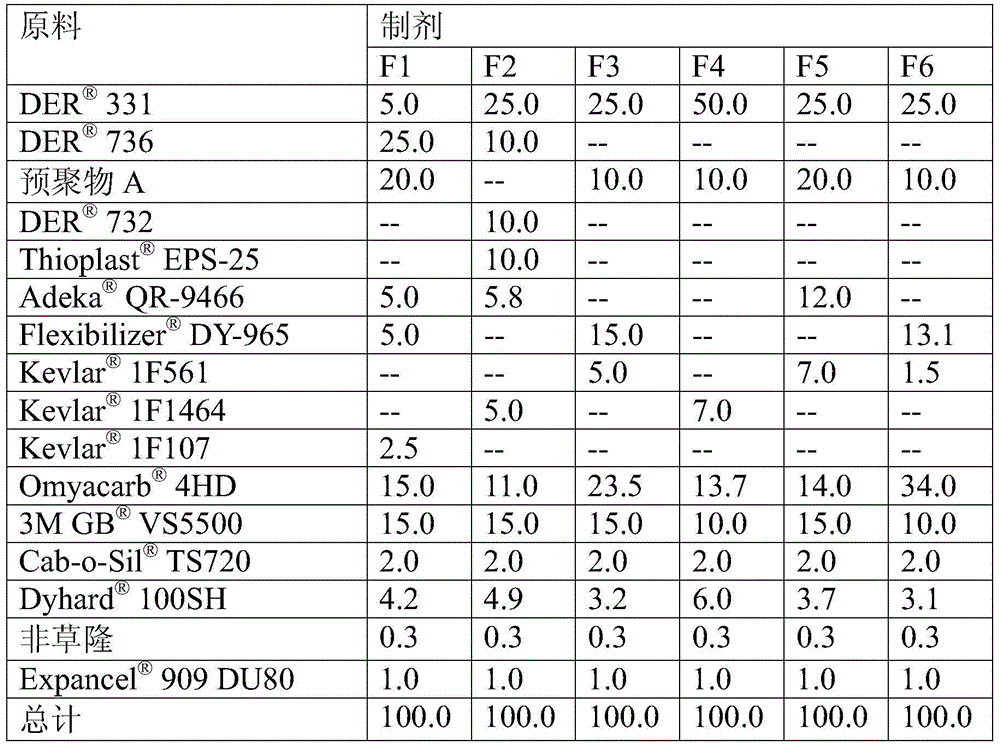

[0165] 1 Preparation of formulations

[0166] The following thermally expandable formulations were prepared.

[0167] Quantitative data are expressed in percent by weight unless otherwise stated.

[0168] Table 1:

[0169]

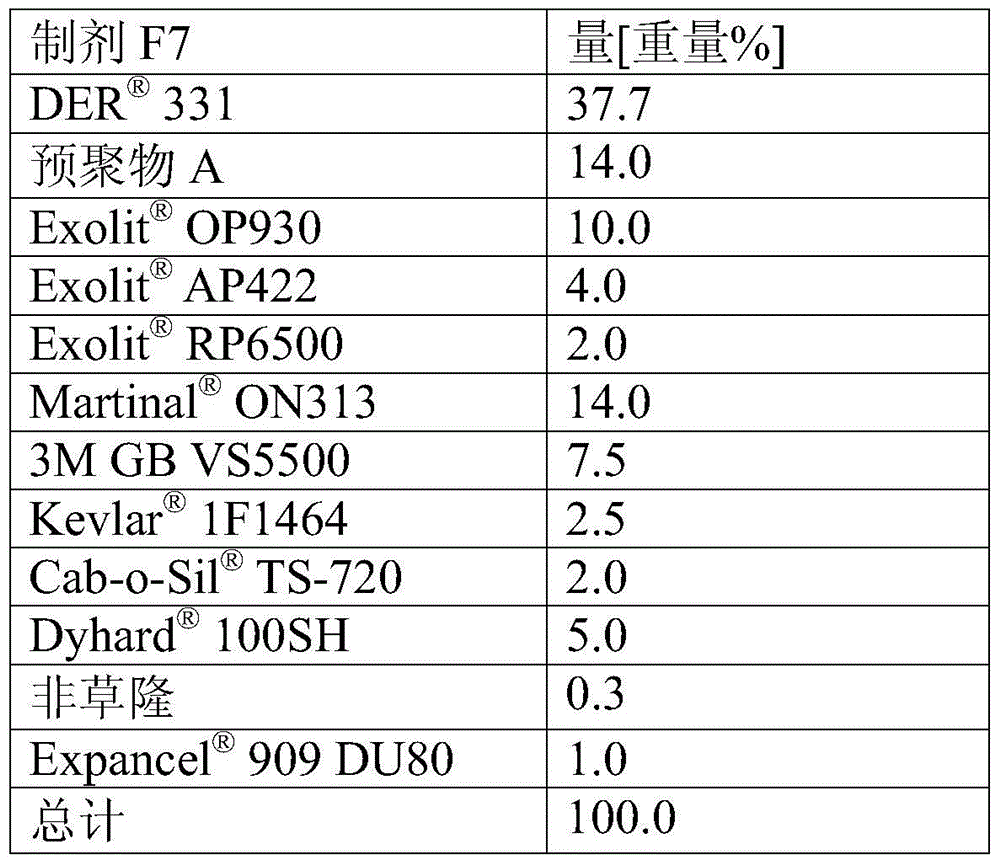

[0170] In addition, the following thermally expandable formulations of the present invention additionally containing a flame retardant were prepared:

[0171]

[0172] 2. List of goods used

[0173] VS5500 hollow glass spheres; manufacturer 3M; density 0.38g / cm 3

[0174] QR-9466 Modified polyurethane resin; manufacturer is Adeka

[0175] TS-720 Silica, fumed amorphous silica, manufactured by Cabot

[0176] 331 Reaction product of bisphenol A and epichlorohydrin; EEW is about 187g / eq; viscosity at 25°C is 12.5Pa*s; manufacturer is Dow

[0177] 732 reaction product of epichlorohydrin and polypropylene glycol; EEW is about 320g / eq; viscosity at 25°C is 0.034Pa*s; manufacturer is Dow

[0178] 736 reaction product of epichlorohydrin a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com