Atomic layer deposition method and apparatuses

A technology for atomic layer deposition and deposition of materials, which is applied in the field of deposition reactors and can solve problems such as complex devices of ALD reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

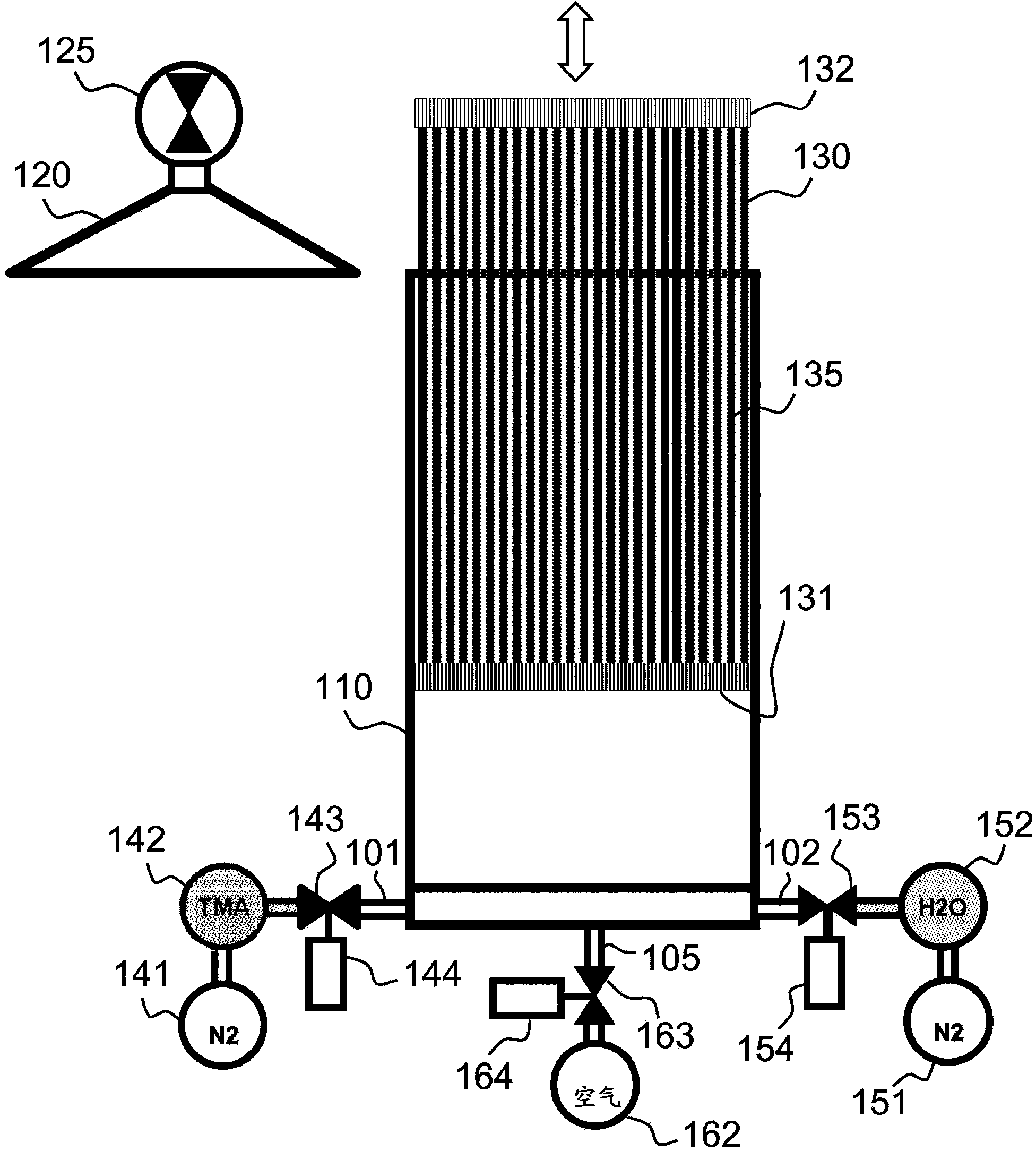

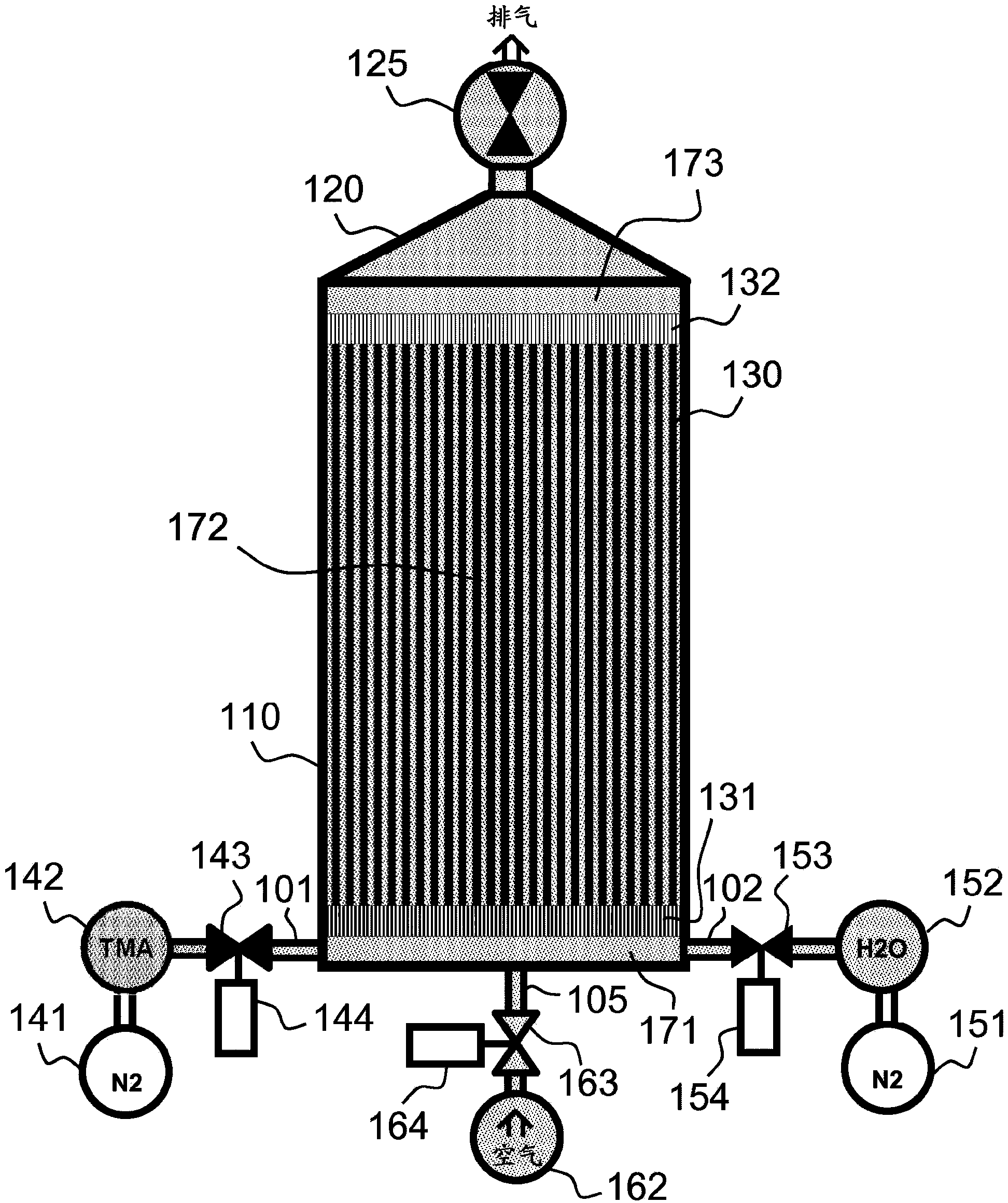

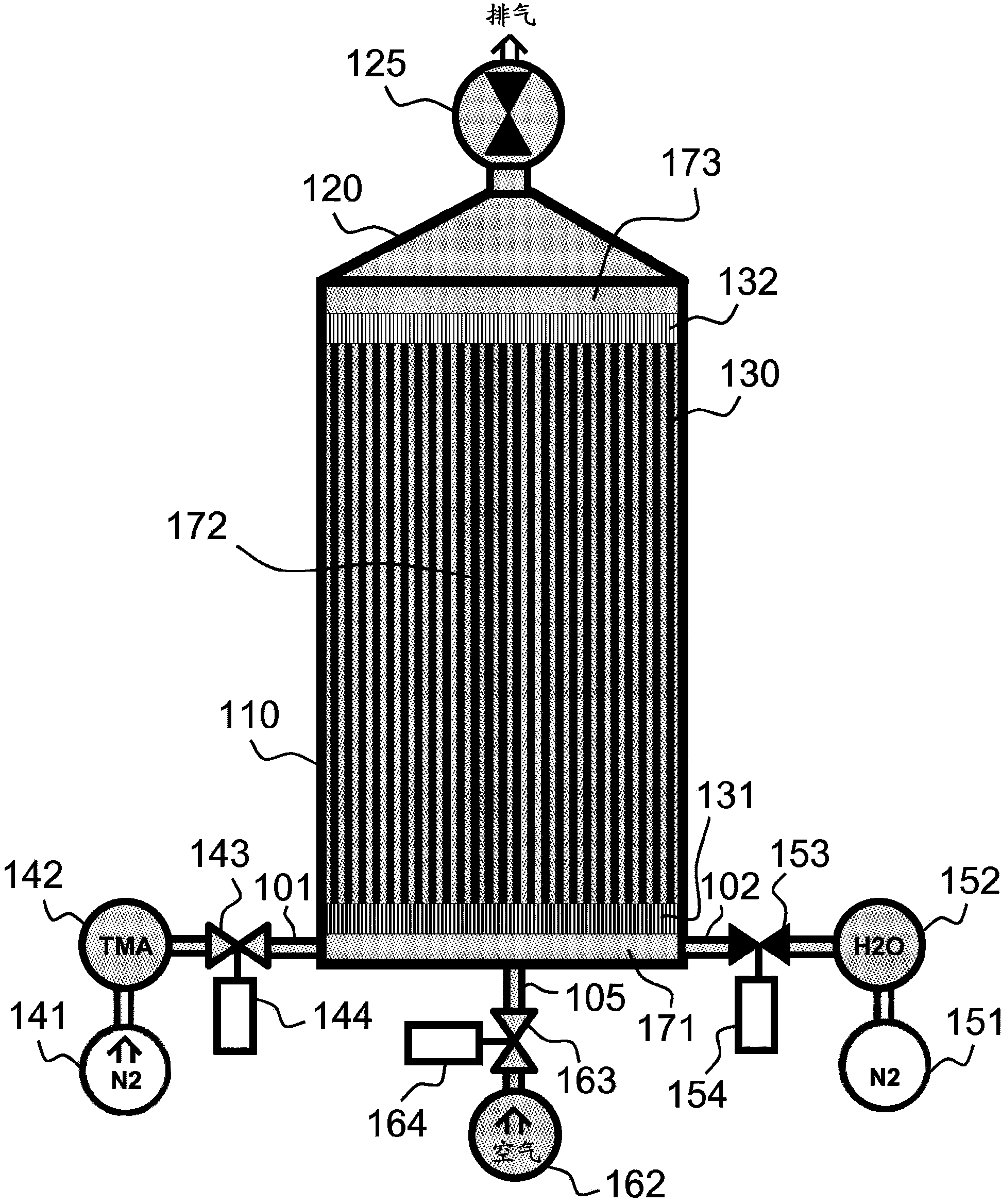

[0059] In the following description, atomic layer deposition (ALD) technology is used as an example. The basis of the growth mechanism of ALD is known to the skilled person. As mentioned in the introduction of this patent application, ALD is a special chemical deposition method based on the sequential introduction of at least two reactive precursor substances to at least one substrate. The substrate, or in many cases a batch of substrates, is located in the reaction space. The reaction space is usually heated. The basic growth mechanism of ALD relies on the difference in bond strength between chemical adsorption (chemical adsorption) and physical adsorption (physical adsorption). During the deposition process, ALD uses chemical adsorption and eliminates physical adsorption. In the chemical adsorption process, a strong chemical bond is formed between one or more atoms on the surface of the solid phase and molecules arriving from the gas phase. The bonding by physical adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com