Coating color evaluation method

An evaluation method and a coloring technology, which are applied to color measurement devices, color measurement using color charts, color measurement using electric radiation detectors, etc., can solve the problems of complex changes in metallic color painting, difficulty in sorting or evaluation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

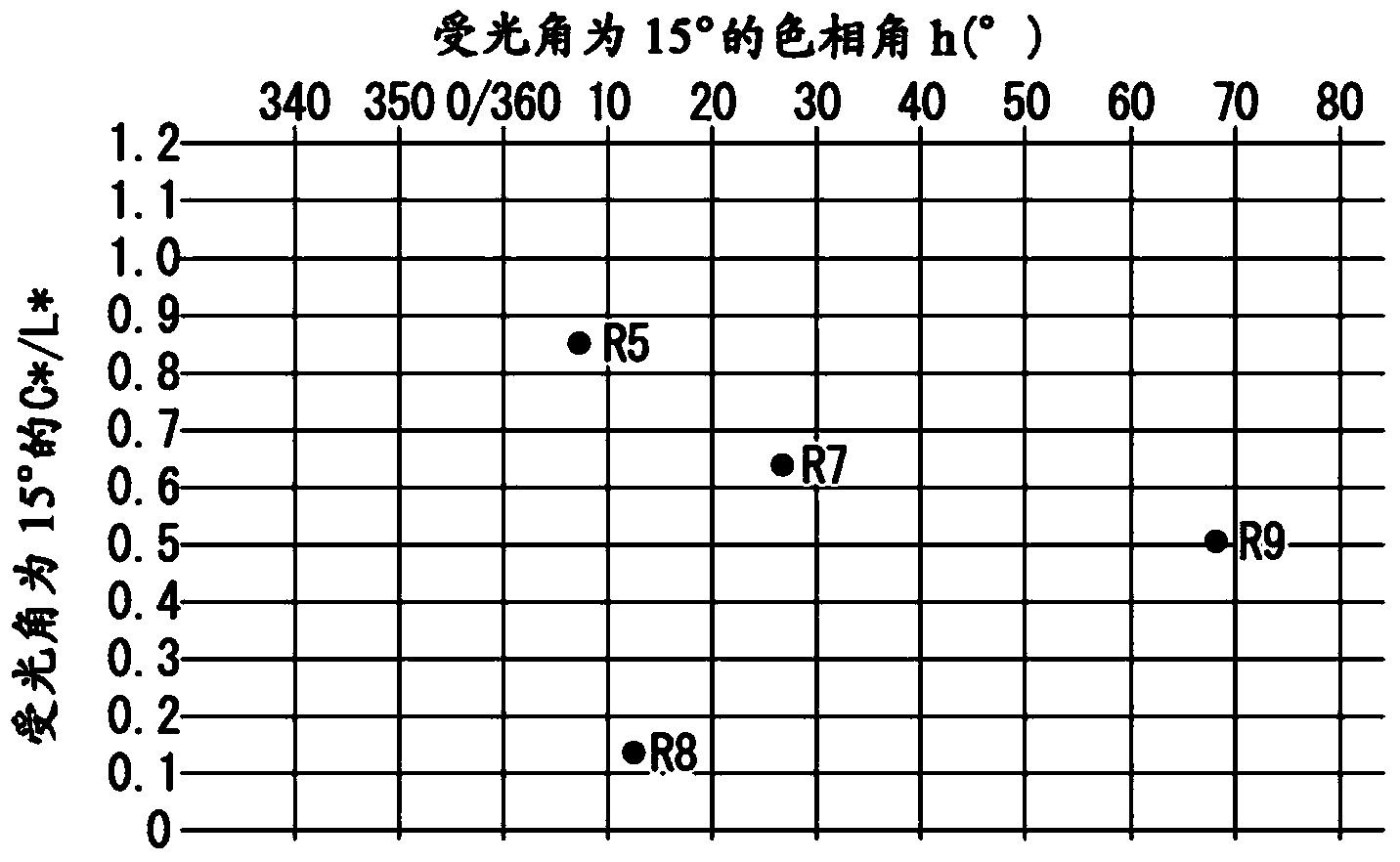

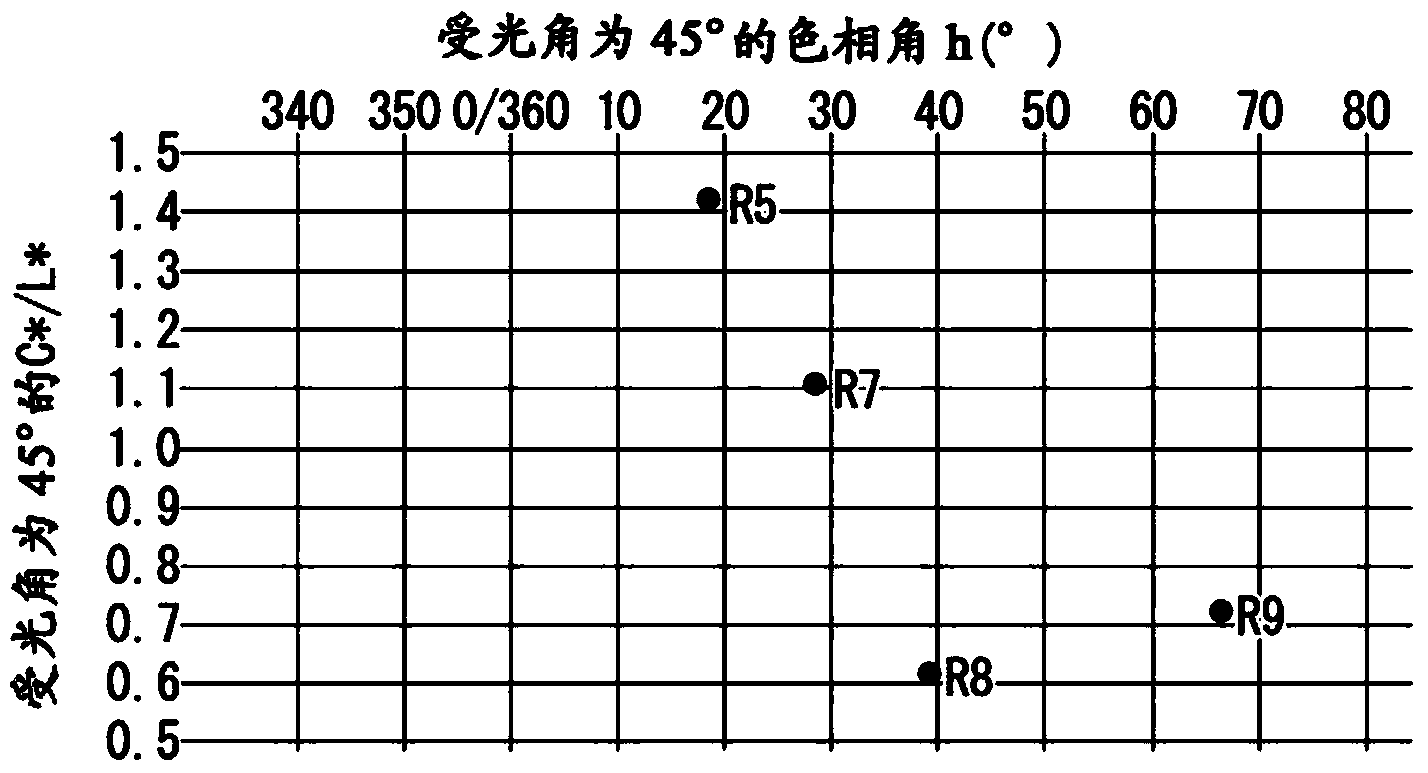

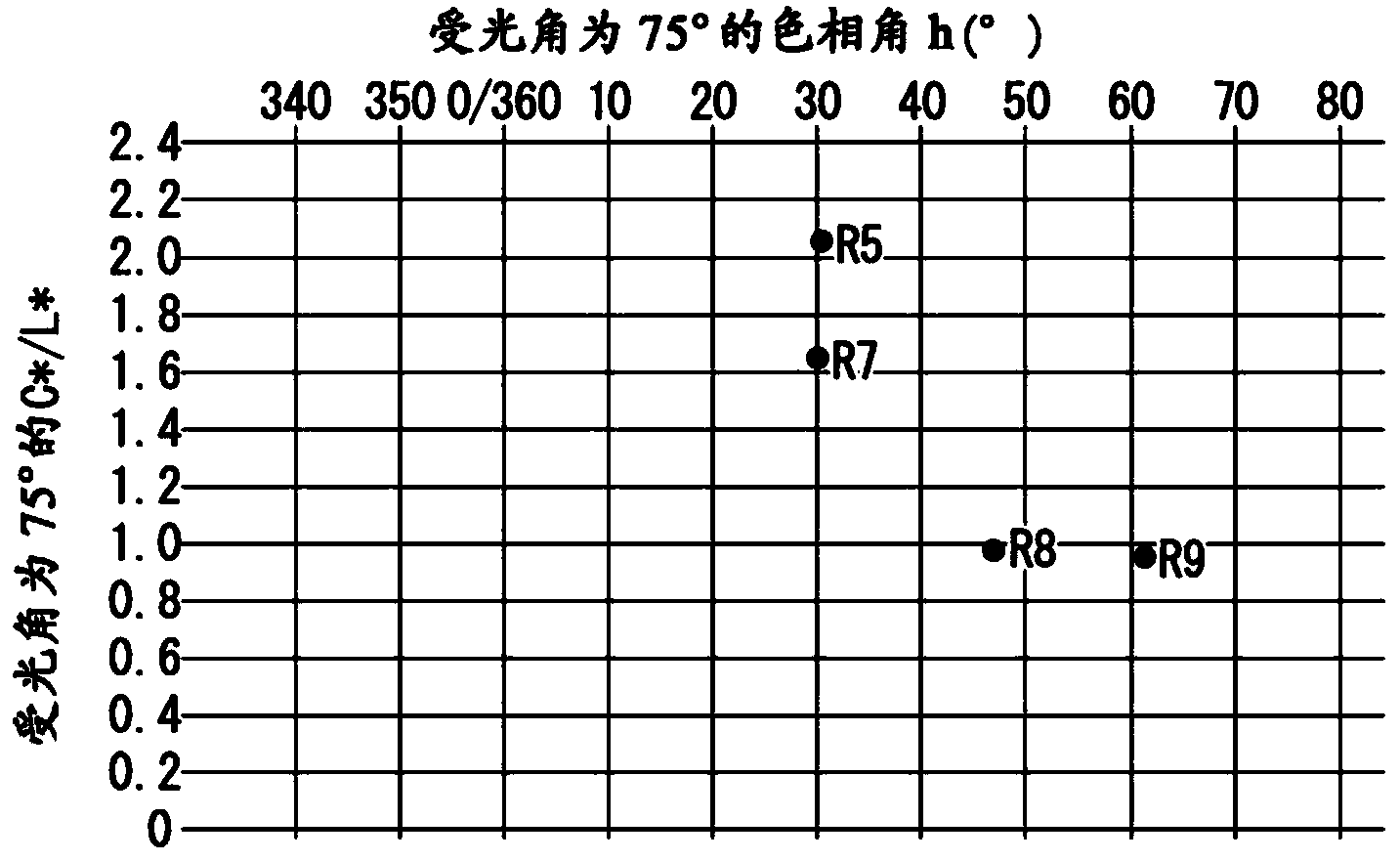

[0058] In the first embodiment of the evaluation method of coloring according to the present invention, the coating film of the above-mentioned photoluminescent paint is produced, the spectral reflectance is measured according to a predetermined light receiving angle, and the L*C*h chromaticity diagram is calculated from the spectral reflectance. The ratio of the brightness L* to the chroma C* is C* / L*. Furthermore, the above-mentioned C* / L* is respectively obtained for a plurality of photoluminescent paints, and the value of the above-mentioned C* / L* is expressed on one coordinate axis (the first coordinate axis), and other parameters are expressed on another one. A graph is drawn by arranging coordinate points representing the coloring of a plurality of photoluminescent paints on a two-dimensional plane represented by a coordinate axis (second coordinate axis). When C* / L* is used as the axis, compared with the case where C* is used as the axis, the spread is closer to the vi...

Embodiment

[0090] Hereinafter, the present invention will be specifically described based on examples.

[0091] (How to make the coated board)

[0092] An intermediate-coated panel on which a coating film of N-6 gray-intermediate paint was formed in advance was prepared, and after solvent degreasing and cleaning, the photoluminescence paint was applied to the coated panel as a cured coating film by air spraying so as to have a thickness of 20 μm. After that, it was left to stand in a laboratory at a room temperature of about 20° C. for 15 minutes, and then, the clear paint was applied on the coated panel as a cured coating film by air spraying so as to have a thickness of 30 μm. After that, it was left to stand in a laboratory at a room temperature of about 20° C. for 15 minutes, and then the clear paint was applied by air spraying as a cured coating film to a thickness of 40 μm on the coated panel. Then, it was left to stand in a laboratory at a room temperature of about 20° C. for 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com