Magnetic recording medium for heat-assisted magnetic recording

一种磁记录介质、辅助磁的技术,应用在磁记录、数据记录、图案记录载体等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

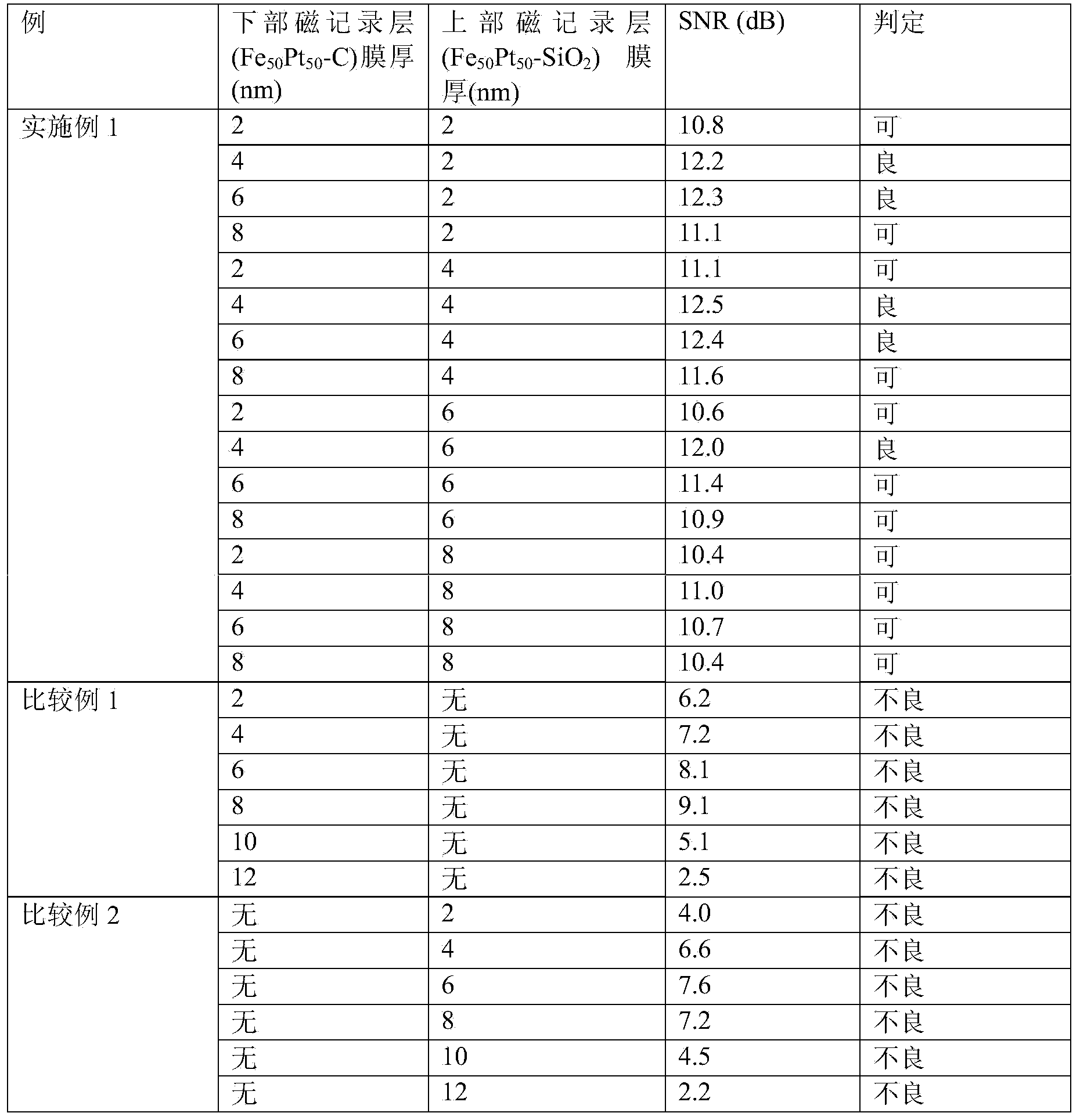

[0052] (Example 1)

[0053] A chemically strengthened glass substrate (N-10 glass substrate manufactured by HOYA Corporation) having a smooth surface was washed to prepare a non-magnetic substrate 10 . The cleaned non-magnetic substrate 10 is introduced into a sputtering device. CuSi heat dissipation layer 20 having a film thickness of 50 nm was formed by DC magnetron sputtering using a CuSi target in Ar gas at a pressure of 0.67 Pa.

[0054] Next, a two-layer structure seed layer 30 composed of a Ta layer and an MgO layer was formed. Specifically, a Ta layer having a film thickness of 10 nm was formed by DC magnetron sputtering using a Ta target in Ar gas at a pressure of 0.67 Pa. Next, the laminated body on which the Ta layer was formed was heated to 250° C., and a MgO layer with a film thickness of 5 nm was formed by RF sputtering using an MgO target in Ar gas at a pressure of 0.06 Pa, thereby obtaining the seed layer 30 .

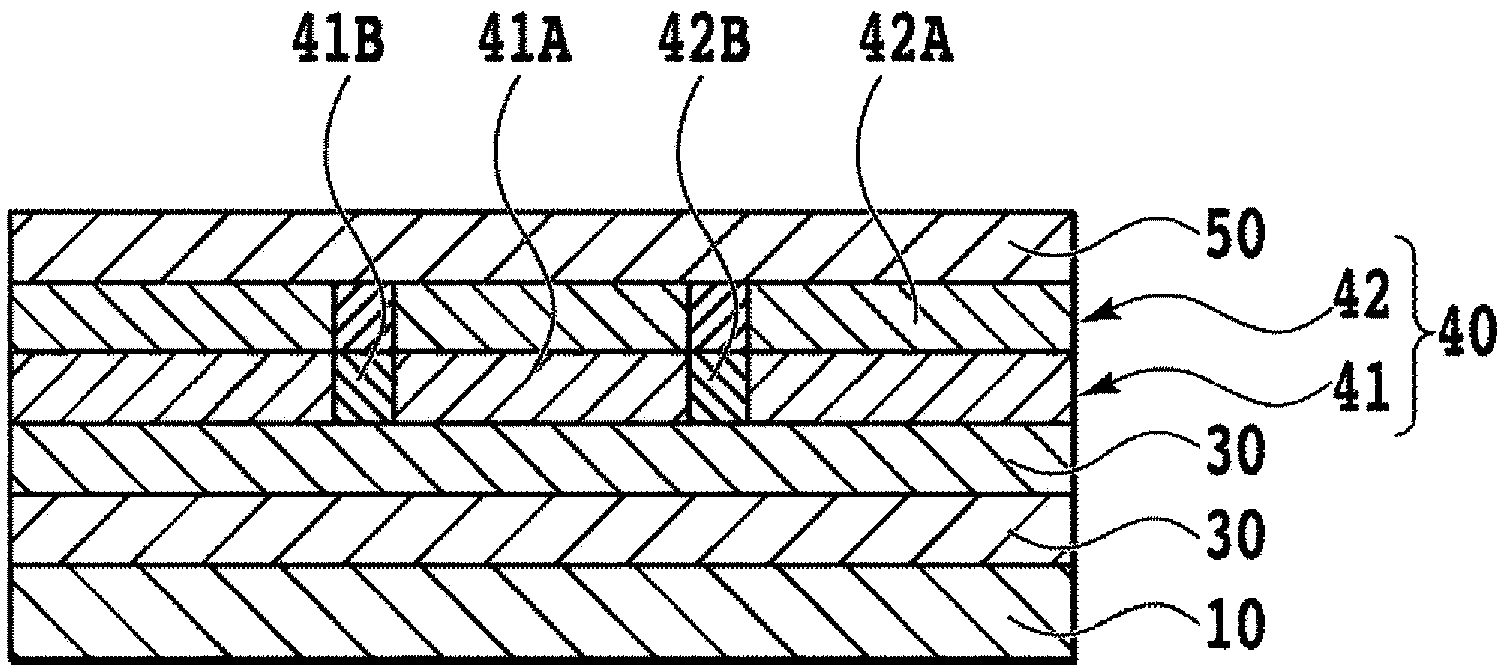

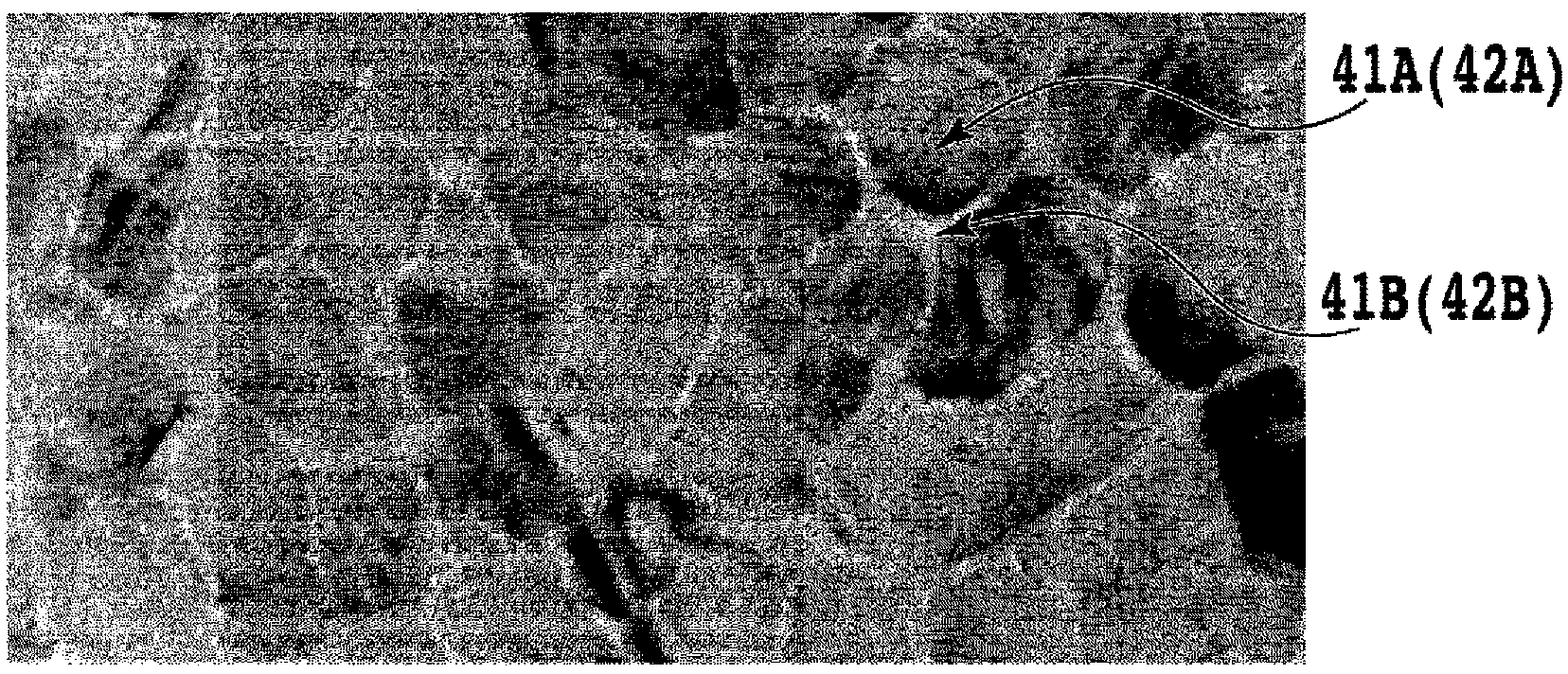

[0055] Next, the laminated body on which the s...

Embodiment 2

[0059] In addition to using mixed Fe 50 Pt 50 and TiO 2 75% by volume (Fe 50 Pt 50 )-25vol%TiO 2 target, formed by Fe 50 Pt 50 -TiO 2 Except for the configuration of the upper magnetic recording layer 42, the same procedure as in Example 1 was repeated to obtain a magnetic recording medium. In this embodiment, the film thicknesses of the lower magnetic recording layer 41 and the upper magnetic recording layer 42 are also varied within the range of 2 to 8 nm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com