Fertilizer

A technology of a fertilizer applicator and a transmission mechanism, which is applied to fertilizer applicators, fertilizer distributors, applications, etc., can solve the problems of clogging of fertilizer pipes, low fertilizer efficiency, slow moving speed, etc., and achieves improved backfill efficiency, reasonable structural arrangement, and transmission. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

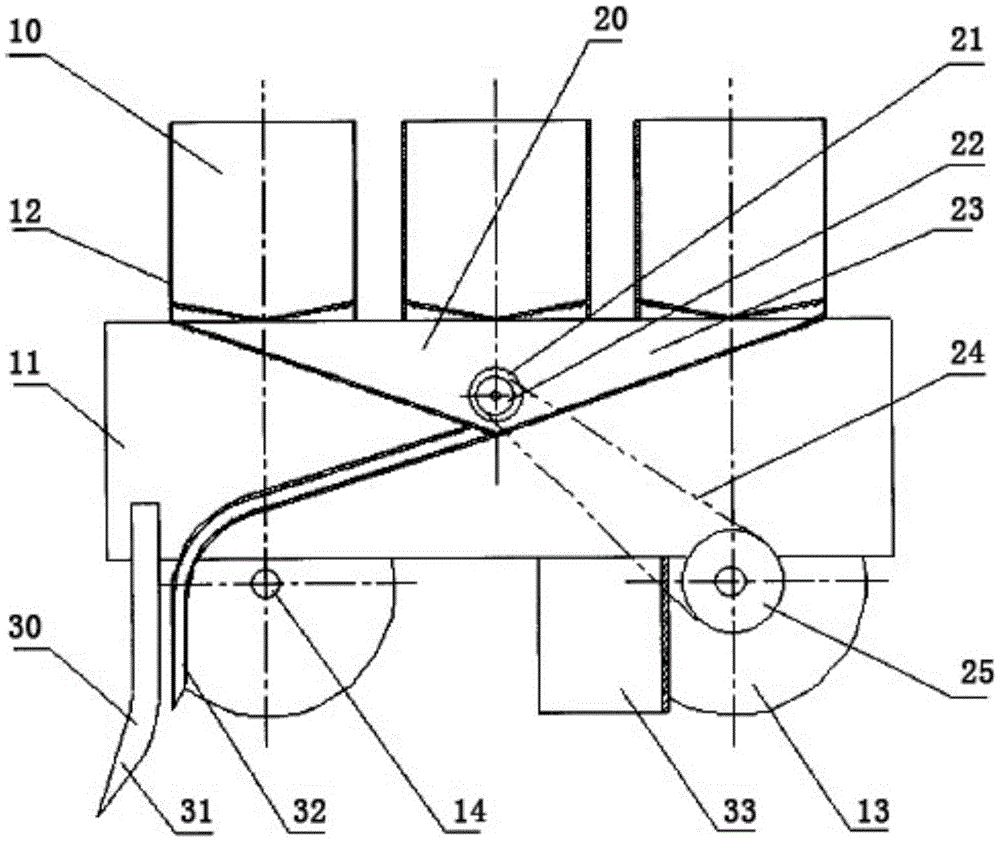

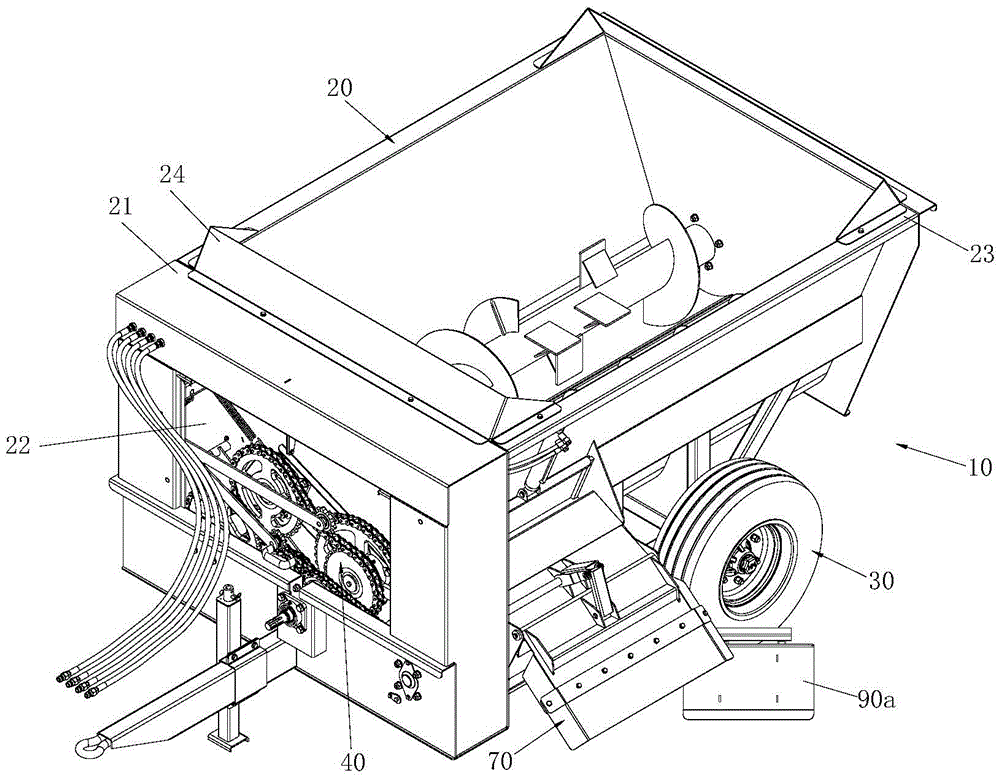

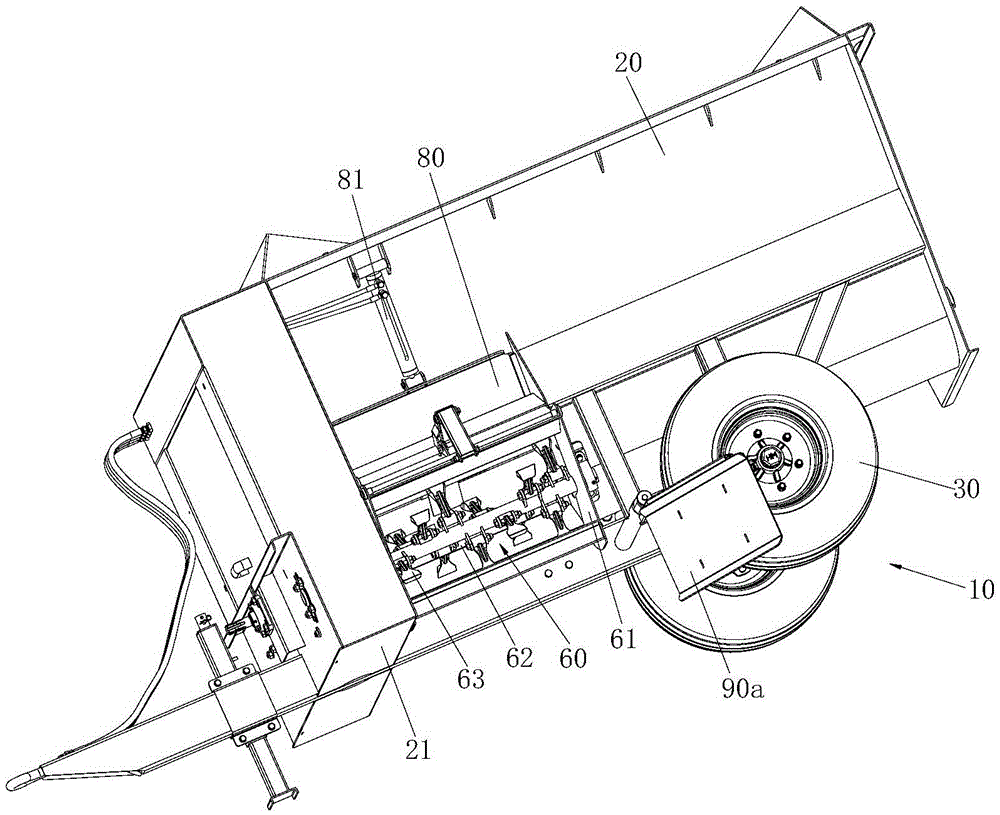

[0034] refer to Figure 2 to Figure 6 , The fertilizer applicator 10 of the present invention includes a material box 20 , a wheel 30 , a transmission mechanism 40 , a feeding auger and a fertilizer application mechanism 60 . The structure of each part is described in detail below:

[0035] At first what needs to be explained is the orientation problem. In the present invention, the front end and the rear end of the feed box are defined. Shown) under the action of power, make feed box 20 move according to the direction of traction force, therefore, the front end is the end of feed box close to traction device, and the rear end is the end of feed box away from traction device.

[0036] refer to figure 2, the top of hopper 20 has opening, and the space that is used for containing fertilizer of hopper is the bucket shape that is up big and down is small, and this bucket shape can be convenient to fertilizer and slides down automatically because its inner wall surface is the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com