Friction stir welding seam welding and spot welding integrated spindle

A technology of friction stirring and welding seams, which is applied to welding equipment, non-electric welding equipment, metal processing equipment, etc., to achieve the effects of improving backfill efficiency, accelerating temperature rise speed, and increasing constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

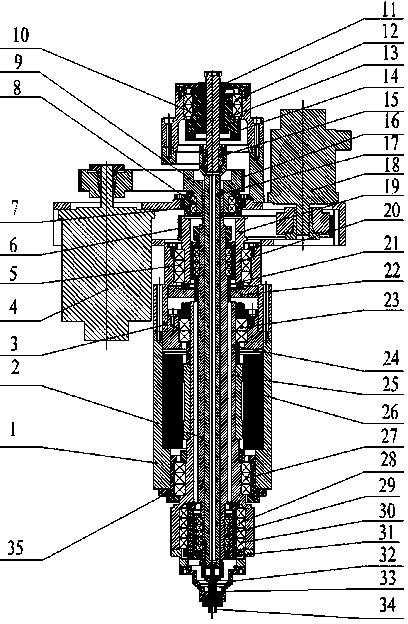

[0012] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

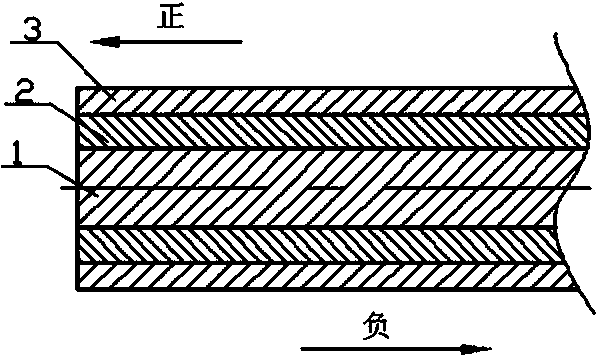

[0013] see figure 1 The friction stir welding seam welding and spot welding integrated spindle of the present invention includes a friction stir welding spindle head having a stirring pin 1 and a stirring sleeve 2 , a driving device and an outer sleeve 3 . The stirring needle 1 is located in the stirring sleeve 2 . The stirring sleeve 2 and the stirring needle 1 are located in the outer sleeve 3 and form a double-moving ring structure together with the outer sleeve 3 . The driving device drives the outer sleeve 3 to rotate around the axis of the stirring needle 1 . The stirring sleeve 2 can move positively and negatively relative to the outer sleeve 3 (assuming that the outer sleeve 3 does not move); the stirring needle 1 can move positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com