A method of using a small-caliber copper round pipe tearer

A small-caliber, round pipe technology, applied in the direction of pipe shearing devices, shearing equipment, shearing devices, etc., can solve the problems of finger scratches, reduce the effective length of copper pipes, waste, etc., and achieve the effect of reducing the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

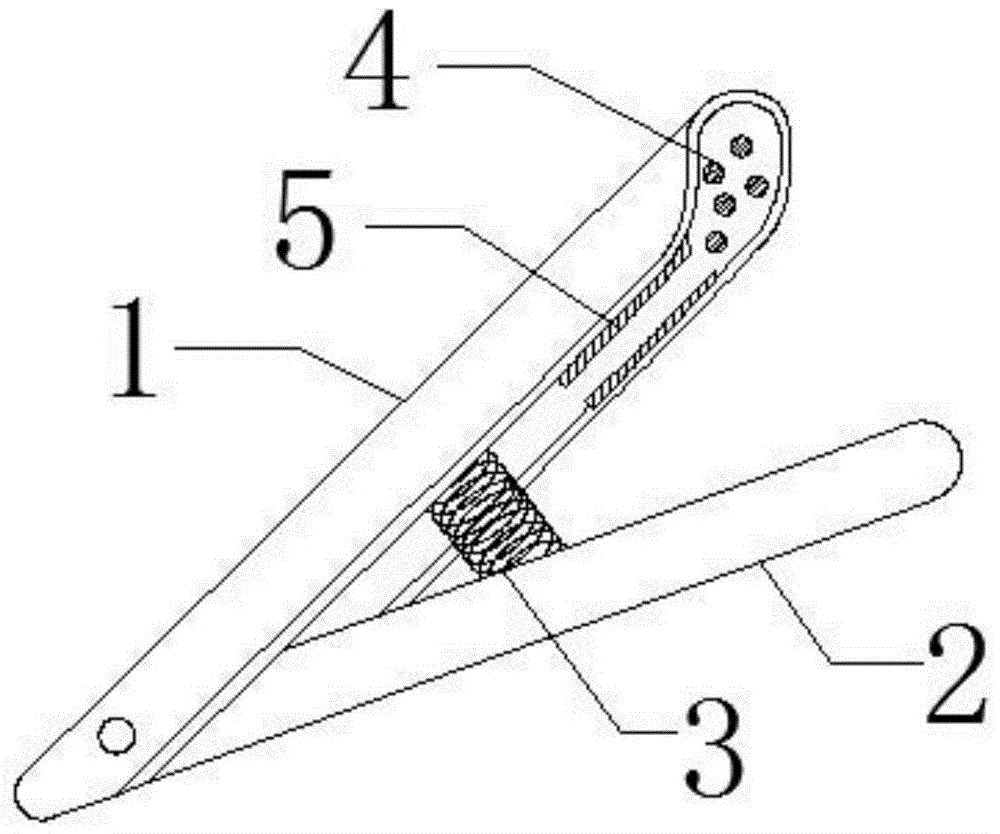

[0020] Embodiment 1: a kind of small-diameter copper pipe tearer, its structure is as figure 1 As shown: it includes a gland 1 with an arc-shaped interior, the front end of the gland 1 is a smooth transition structure, the rear end of the gland 1 is hinged with a cylindrical lining 2, and the two sides of the inner wall of the gland 1 are respectively provided with a split blade 5, and the distance between the two splitting blades 5 is greater than the diameter of the cylindrical lining 2, and a spring 3 connects the gland 1 with the cylindrical lining 2.

[0021] A viscous substance 4 is provided on the inner wall of the front end of the gland 1 .

[0022] The sticky substance 4 is a self-adhesive.

[0023] The lengths of the two cutting edges 5 are the same.

[0024] The front end of the cylindrical liner 2 has a hemispherical structure.

[0025] The present invention also provides a method for using the small-diameter copper pipe tearer of this embodiment, the steps are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap