A kind of sanding machine which is convenient for adjusting the tightness of the sanding belt

A sand belt and sand machine technology, which is applied in the field of sand machines, can solve the problems of hindering the installation of the sand belt and adjusting the tightness of the sand belt, damaging the working environment, and inconvenient distance fixing, so as to reduce the difficulty of construction technology and reduce residual products , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

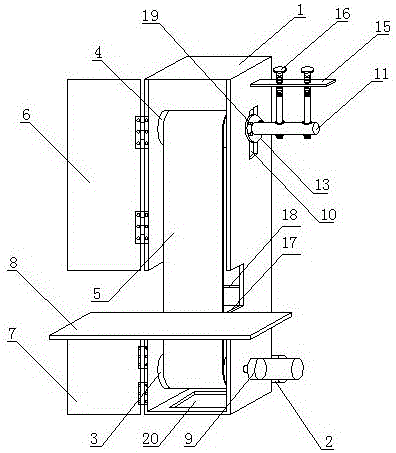

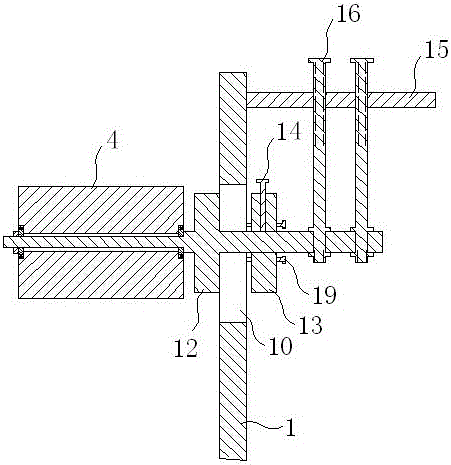

[0010] Attached below figure 1 And attached figure 2 A kind of sanding machine of the present invention that is convenient to adjust the tightness of the sanding belt will be further described.

[0011] A kind of sand skin machine that is convenient to adjust the tightness of sand belt of the present invention is to be made of cabinet 1, motor 2, drive roller 3, driven roller 4 and sand belt 5, and its described cabinet 1 is provided with upper opening door 6 and The vertical casing of the lower door 7, the setting of the upper door 6 and the lower door 7 are convenient for replacing the abrasive belt and cleaning the waste in the cabinet 1, and the middle part of the upper door 6 and the lower door 7 is provided with a horizontal feeding platform 8, The upper part of the material table 8 is provided with a grinding port 17, the lower part of the cabinet 1 is horizontally provided with a transmission roller 3, and the transmission wheel 9 of the transmission roller 3 outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com