Combined type stream welding machine and working principle thereof

A working principle, welding machine technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of poor generality of production lines, increased production costs, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

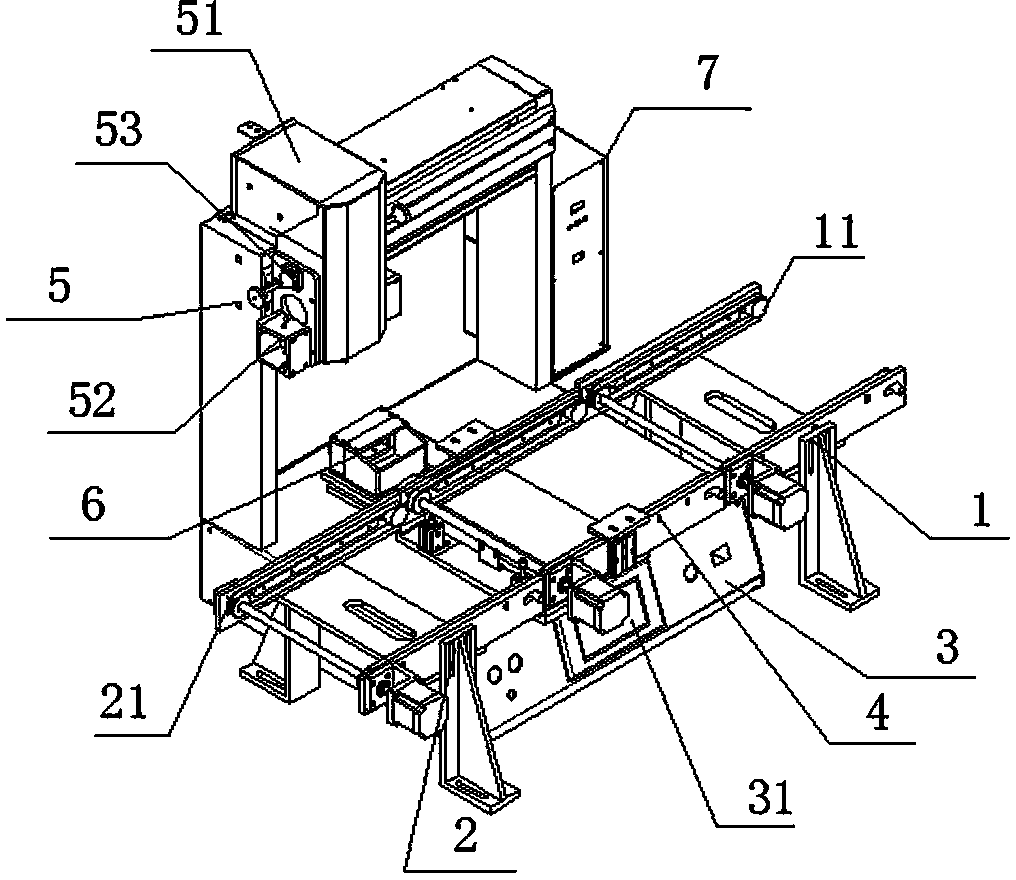

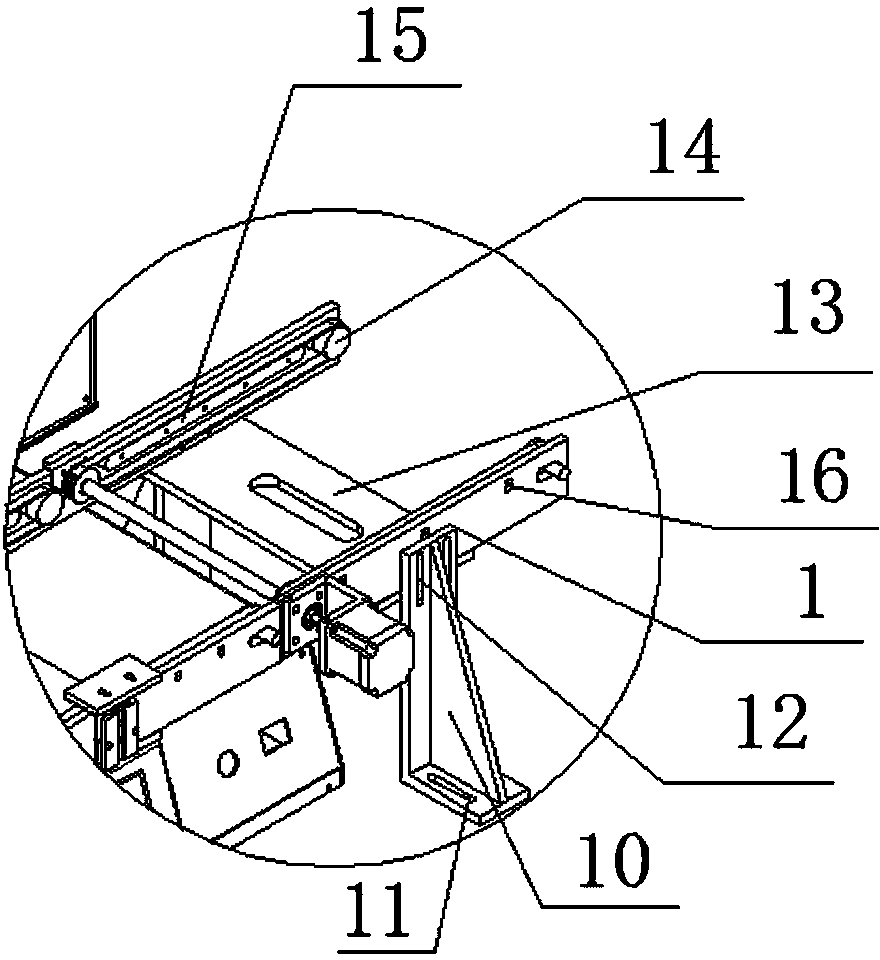

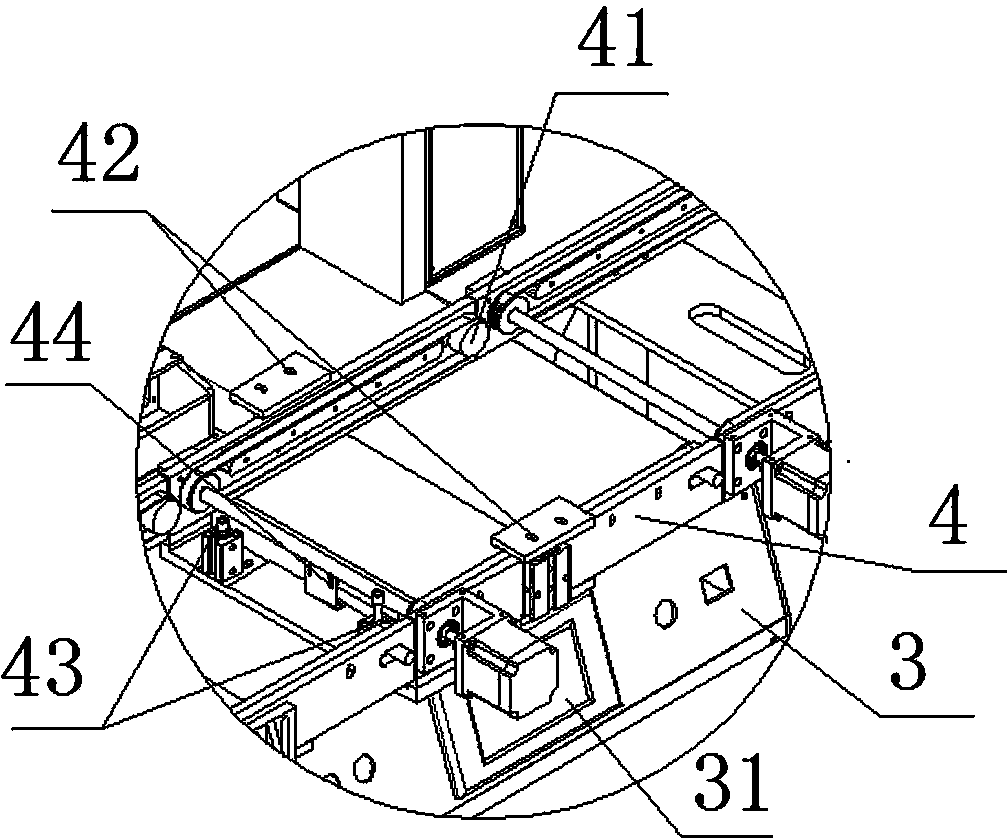

[0014] In this example, refer to Figure 1 to Figure 4 Shown, a kind of combined flowing water welding machine and its working principle, comprise material preparation conveying frame 1, discharge conveying frame 2, and be arranged on the workbench 3 between the material conveying frame 1 and the discharging conveying frame 2; Described work The front of table 3 is provided with an industrial control display screen 31 for control operation, and a working conveying frame 4 arranged on the working table 3. The working conveying frame 4 moves back and forth on the working table 3 to convey workpieces. Clamping mechanisms 42 for clamping workpieces are respectively provided, and a working conveyor belt mechanism 41 for conveying workpieces left and right is arranged between the clamping mechanisms 42. Two stoppers for workpieces are provided on the right side of the working conveyor belt mechanism 41. A position mechanism 43, a working infrared detection mechanism 44 for detecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com