Adjustable stop valve

A cut-off valve, adjustable technology, applied in the direction of lifting valves, valve devices, engine components, etc., can solve problems such as difficult cleaning, unfavorable flow adjustment, leakage, etc., and achieve the effect of reducing operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The design will be further described below in conjunction with the accompanying drawings of the description.

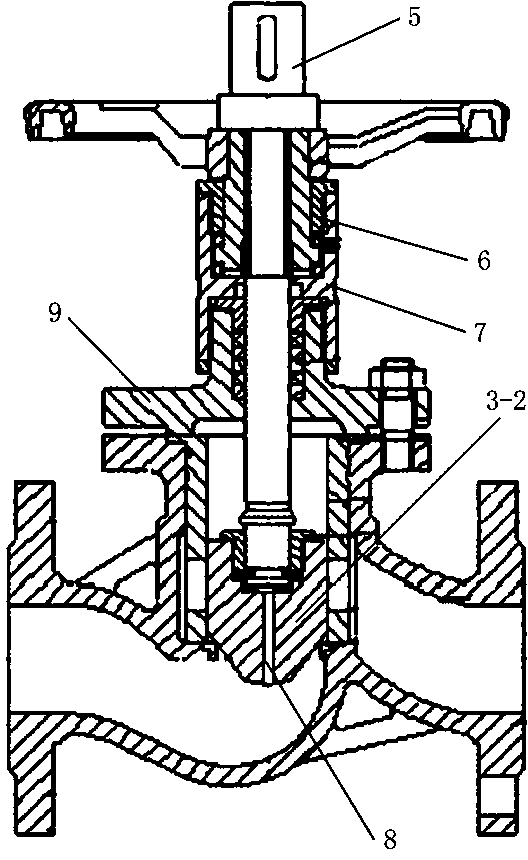

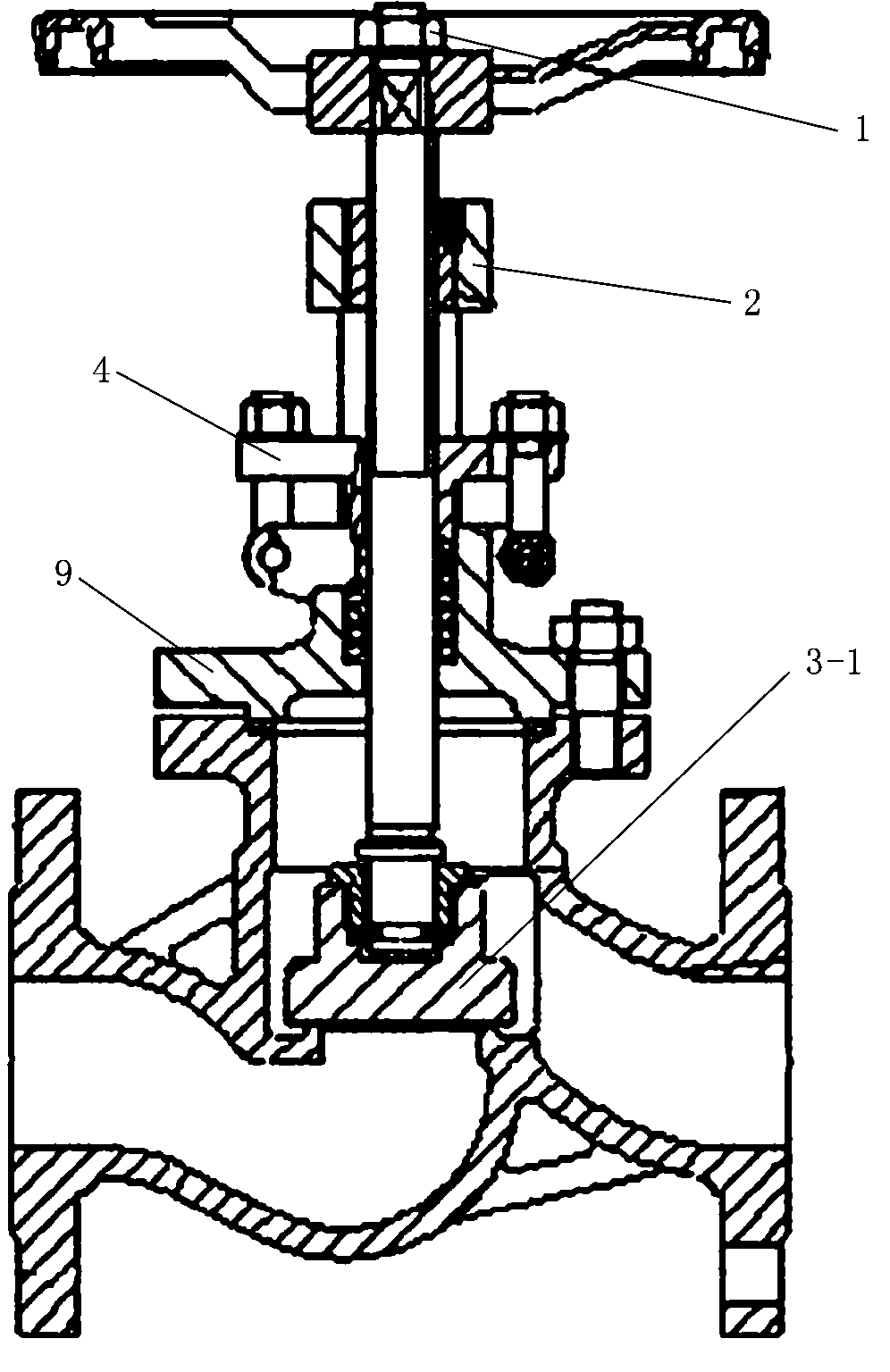

[0017] like figure 1 , 2 As shown, an adjustable stop valve includes a lock nut 1, a valve stem nut 2, a packing gland 4, and a valve disc 3-1, which is characterized in that: the valve disc 3-1 is a conical valve disc 3- 2.

[0018] The valve clack has a tapered structure, and cooperates with the valve sleeve to form a gradual flow passage, which is easy to adjust the flow rate with the valve clack rising and falling.

[0019] Preferred:

[0020] The above-mentioned adjustable cut-off valve is characterized in that: the taper of the conical disc 3-2 is 30°.

[0021] The above-mentioned adjustable stop valve is characterized in that: the conical valve disc 3-2 is also provided with a pressure guiding hole 8, and the pressure guiding hole 8 runs through the conical valve disc 3-2.

[0022] Pressure guide holes are designed at the valve disc and valve stem t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com