Camera installing mechanism convenient to move

A technology of installation mechanism and camera, applied in the direction of supporting machine, image communication, mechanical equipment, etc., can solve unsightly installation traces, only remove the installation camera mechanism installed on the wall, and then re-install and install the camera mechanism damage and other problems to achieve the effect of perfecting the explosion-proof effect, maintaining the appearance and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

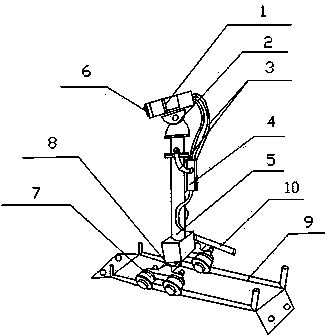

[0020] like figure 1 As shown, the present invention comprises explosion-proof shield 1, explosion-proof electric pan-tilt 2, junction box 4, mounting bracket 5, double roller 7 and slide bar 9, and described explosion-proof shield 1 is installed on the top of explosion-proof electric pan-tilt 2, explosion-proof The bottom of the electric pan / tilt 2 is installed on the mounting bracket 5, and a wiper 6 is also installed on the front end of the explosion-proof shield 1; a fixed steel plate is also welded on the side of the mounting bracket 5, and the junction box 4 is fixedly installed on the fixed steel plate. The bottom of the bracket 5 is connected to two double rollers 7 through a connecting plate 8, and each double roller 7 is stuck on the corresponding slide bar 9; Explosion-proof flexible pipe 3.

[0021] After the camera is installed in the explosion-proof enclosure, the mechanism can be directly fixed to the ground, or installed on the wall. Since a pair of double rol...

Embodiment 2

[0024] The preferred specific structure of this embodiment on the basis of Embodiment 1 is as follows: the two double rollers 7 are symmetrical about the mounting bracket 5, the two sliding bars 9 are parallel to each other, and mounting plates are provided on both sides of the two sliding bars 9. Two parallel sliding rods are set to make the mounting bracket more stable during the sliding process without deviation.

[0025] Both ends of the slide bar 9 are connected vertically to the stop bar.

[0026] A handle 10 is also provided on the side of the mounting bracket 5, and the handle 10 can rotate around the mounting point. The handle can be held to slide, and after the sliding position is determined, the handle can also be turned to support the ground or the wall to limit the position of the camera installation mechanism.

[0027] The junction box 4 is also connected with power lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com