Pipeline system of first condensation jar

A pipeline system and condensing tank technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of wasting time and energy, and achieve the effect of avoiding downtime maintenance and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

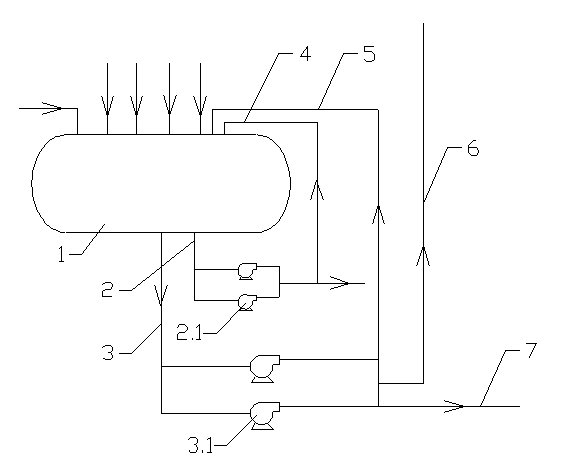

[0017] see figure 1 , the pipeline system of a first condensation tank involved in the present invention, it includes a first condensation tank 1, a plurality of pipelines are arranged on the upper part of the first condensation tank 1, and the pipelines include heat medium feed pipelines, preheating Heater discharge pipeline, cylinder discharge pipeline, esterification heat exchanger discharge pipeline and cold condensation tank return pipeline, the lower part of the first condensation tank 1 is provided with a first discharge pipeline 2 and a second discharge pipeline Pipeline 3, a first return pipeline 4 is connected between the rear section of the first discharge pipeline 2 and the return port of the first condensation tank 1, and the front section of the first discharge pipeline 2 is provided in parallel with two The first output pump 2.1, the second return pipeline 5 is connected between the rear section of the second discharge pipeline 3 and the material return port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com